For the Royal Australian Navy, Technological Leap Starts Small

Driven by the need to organically protect maritime Task Groups from the threat of sea mines, the Royal Australian Navy is introducing a deployable Mine Counter-Measures (MCM) capability under the first phase of Project SEA 1778.

The Royal Australian Navy’s (RAN) SEA 1778 deployable Mine Counter-Measures (MCM) capability is both a small step forward in the spiral development process and a “technological leap” into autonomy.”

The RAN is looking to replace its four legacy Huon-class minehunter coastal ships (MHCs) with a new deployable MCM capability. The lead ship in the class, HMAS Huon (M 82) will be 21 years old this May. The MHCs are slow and are not always available where and when they are needed. Furthermore, they need to enter mined areas to find the mines.

Captain Bryan Parker, the RAN’s Commander Mine Warfare, Clearance Diving, Hydrographic, Meteorological, Oceanographic and Patrol Force (COMMHP), said the Task Group MCM capability aimed to provide a tactical capability essential to reducing the hazard of mines in the littoral maritime domain for Navy’s deployed Fleet, while also minimizing direct exposure of its personnel to dangerous sea mines.

“By its very nature, MCM operations are a time-consuming task and conventional minehunters have a relatively slow speed of advance compared to our other warships. We are aiming to provide an MCM capability in-stride with, or in some cases ahead of, deploying maritime task groups to effectively speed up the time taken on this important function and enabling maritime maneuver,” Parker said.

“We need an organic MCM capability that’s designed to burst out of the back of the Landing Helicopter Dock (LHD) and clear a lane to the beach so the landing force can go ashore,” said Cmdr. Mick Parker, the operational requirements sponsor for mine warfare at the Navy Strategic Command. “SEA 1778 provides an initial interim MCM effect for a single task group.”

The SEA 1778 package is relatively small. The entire system can be containerized, shipped to a task group such as the RAN’s amphibious ships, the new Arafura-class OPV or the Hunter-class future frigate. It can then be dispatched to another location if necessary.

It uses manned and unmanned surface vessels and autonomous underwater vehicles that can search an area from a safe distance.

The procurement is also relatively modest, so the RAN can take gradual steps towards using autonomous systems.

“It’s a small buy so we can test the water, form our concepts, understand our rate of effort, the workforce requirement, conduct the integration, and springboard into the strategy,” Parker said. “It’s a toe-in-the-water of autonomy.”

Thales Australia is the prime contractor for SEA 1778 PH I, and has assembled a world-class team, starting with the five 38-foot support boats made by Steber International of Taree, New South Wales.

The Rotinor Black Shadow diver delivery system can be used to place detonating charges near mines. (Rotinor image)

The Rotinor Black Shadow diver delivery system can be used to place detonating charges near mines. (Rotinor image)

The boats are the same, all though two of them will also have be equipped with a control system from ECA of La Garde, France so they can be operated remotely. “The unmanned boats (USVs) can tow the Australian Minesweeping System (AMAS) sweep, made by Thales, which is a towed magnetic and acoustic multi-influence sweep for detonating influence mines. If you know there’s a mine out there, you can send out one of the unmanned boats and trigger the mine using the AMAS,” said Troy Stephen who is the Director of the Underwater Systems Business for Thales Australia. “The AMAS is a proven capability used by many navies around the world.”

General Dynamics Mission Systems Bluefin Robotics General Dynamics Mission Systems Bluefin Robotics of Quincy, Massachusetts, has delivered both 9-inch and 12-inch diameter Bluefin unmanned underwater vehicles (UUVs) for the program

According to Stephen, both the Bluefin-9 and Bluefin-12 vehicles have good endurance, Stephen said, and yet are small enough to handle with relative ease. The Bluefin-9 is 2-man portable, and can be placed into the water from the boats and retrieved over the transom. The larger AUV uses a stern launch and recovery system on the Steber support boat that has been developed by Thales. Both UUVs are fully autonomous, and feature Sonardyne Solstice high-resolution Multi-Aperture Sonar (MAS); the same Removable Data Storage Module (RDSM); and the same 1.9 kWh Li-ion batteries (the Bluefin-9 has one; the Bluefin-12 has four, so the Bluefin-12 can conduct missions of up to 24 hours or longer).

The Bluefin vehicles have the ability to be configured with automatic target recognition using software from SeeByte of Edinburgh, Scotland, so they can identify mine-like objects onboard the vehicle to create an image of the target, and can return with the data for post processing right on the surface boat.

“We can start looking at the data straight away,” Stephen said. “When we get the vehicle alongside, we can take the hot-swappable hard disk and the battery out, put a new one in, and launch it again to search a new area,” said Stephen. “Not too many other vehicles that can do that. That’s one of the key differentiators of the Bluefin vehicle, and why we chose it.”

Both the Bluefin-9 and Bluefin-12 use commercial off-the-shelf sensors to collect bathymetric and environmental data, including data on water currents, temperature, salinity and turbidity; the Nortek Doppler Velocity Log (DVLs) for current measurements; and the Sonardyne Solstice Multi-Aperture Sonar (MAS) for high-resolution imagery even in murky littoral waters.

“Solstice uses multiple elements to generate an image, and in doing that, we improve the signal to noise ratio, and in doing that we extend the range,” said Ioseba Tena, the global business manager for defence and robotics at Yateley, UK-based Sonardyne International Ltd. “We’re extending the range by virtue of doing a better job of how we process and dynamically focus the data, to ensure the best performance in real-time.”

Tena said the Solstice and Bluefin vehicles can “fly” at speeds up to 6 knots, although most UUVs don’t operate that fast. “The beauty with a synthetic aperture sonar is that you get a constant area coverage rate. If you go faster, the range comes down, just by virtue of how the system processes the data. And if you go slower, the range goes up.”

“It’s all about the data,” said Andy Rogers, vice president of undersea systems at General Dynamics Mission Systems. “The Bluefin-9 and Bluefin-12 are able to collect high-resolution data, process that data on-board the vehicle, and deliver actionable information to vehicle operators and decision-makers both during and immediately after a mission.”

Rogers said the vehicles – by design – can be adapted to new missions as they are identified.

The Bluefin-9’s tightly integrated commercial off-the-shelf sensors deliver best-in-class imagery and collect bathymetric and environmental data, including data on water currents, temperature, salinity and turbidity. Designed for detailed hydrographic surveys, the Bluefin-9 is outfitted with Sonardyne Solstice Multi-Aperture Sonar (MAS) that provides high-resolution imagery even in littoral waters. The Bluefin-9 is also equipped with Nortek Doppler Velocity Logs (DVLs) that collect information on water currents up to 30 meters. General Dynamics Mission Systems Bluefin-12. (General Dynamics Mission Systems)

The Bluefin-9’s tightly integrated commercial off-the-shelf sensors deliver best-in-class imagery and collect bathymetric and environmental data, including data on water currents, temperature, salinity and turbidity. Designed for detailed hydrographic surveys, the Bluefin-9 is outfitted with Sonardyne Solstice Multi-Aperture Sonar (MAS) that provides high-resolution imagery even in littoral waters. The Bluefin-9 is also equipped with Nortek Doppler Velocity Logs (DVLs) that collect information on water currents up to 30 meters. General Dynamics Mission Systems Bluefin-12. (General Dynamics Mission Systems)

Stephen said the Bluefin UUVs can also do underwater surveys for harbor clearance or to map out a lane for an amphibious force beach landing. “We’ve tested the Bluefin vehicle with the RAN up in Pittwater, an area to the north of Sydney on the Hawkesbury River, and we’ve had tremendous success. We used the Bluefin to map the bottom, and we found wrecks that nobody knew about. We’re doing experimentation with that data to develop 3D models of the bottom of the ocean. The system also allows for change detection. If we found two objects on the bottom every week for a month, and then a third object shows up, maybe we need to check that out,” said Stephen.

When mines are found and are to be destroyed, the SEA 1778 kit includes the Atlas Elektronik SeaFox (Bremen, Germany) expendable mine neutralization system, as well as the Rotinor (Stuttgart, Germany) Black Shadow diver delivery vehicle to transport divers to place detonation charges near mines, depending on the environment and tactical situation. The MAS Zengrange (Wellington, New Zealand) Command Initiated Detonation Systems (CIDS) is used to initiate the detonation.

In the first phase, the unmanned boats won’t be able to self-deploy the underwater vehicles, but in future phases it is anticipated that the USVs will be enhanced to become fully autonomous and capable of deploying and recovering the UUVs, Stephen said.

As part of the first phase of SEA 1778, the RAN stood up Mine Warfare Team 16 (MWT 16) to operate the four Bluefin-9 UUVs, three Bluefin-12 UUVs, two USVs, three manned MCM Support Boats, and the Seafox Expendable Mine Neutralization System. The team is training on select elements of the system now. MWT 16 will receive the all of its gear later this year. The initial roll-out of the equipment will be the man-portable ‘Bluefin-9’ AUV, for which MWT 16 is undergoing pilot training at Sydney’s Pittwater area. Stephen said the Bluefin-12 has now also completed acceptance trials at Pittwater.

Lt. Cmdr. John Sutherland, who command s MWT 16, said RAN’s joint commitment to training with Defence Science and Technology Group (DSTG) and industry partners such as the Australian Maritime College, is bolstering the team’s capacity to hit the Initial Operating Capability milestone.

“We’ve been working with partners to upskill our people in the operation of AUV technology and provide them with invaluable underpinning AUV knowledge required to execute activities,” Sutherland said.

According to Sutherland, the new autonomous and unmanned technologies will allow the RAN to search for, classify, identify and dispose of sea mines more safely and efficiently and limit the danger factor presented when personnel are directly involving in mine removal and destruction. “There’s a lot of training, testing and trialing involved, but we’re all aware of the significance of this new generation of technology, the team are making an important contribution to Navy’s leading-edge capability and mission to fight and win at sea.”

“We’ve conducted several rounds of training in operations and maintenance for Thales and RAN operators,” said Rogers. “Our modular systems allow operators to replace components themselves which increases operational availability.”

Advantages for naval applications of autonomous platforms and systems are many. But deciding which systems to use, and how to share the capabilities between men and machines, can be daunting. This is especially true in the area of naval mine warfare. The more machines can do, while keeping Sailors safely out of a minefield, the better. But the technology is still evolving. For the RAN, the move towards autonomous MCM is being conducted with a modest and incremental low-risk approach.

Cmdr. Parker, the SEA 1778 PH I program manager, said Phase I will be a learning experience. “It’s a small buy so we can test the water, form our concepts, understand our rate of effort the workforce requirement, conduct the integration, and springboard into the strategy.”

“In the modern warfare space, the speed and multiplicity of what will be occurring, such as swarms and counter swarms, means it’s going to be a busy place. And that busy place may rise to what is beyond human capability in many of these terms,” said Cmdr. Paul Hornsby, the Navy lead for Autonomous Warfare Systems, which includes the platforms, payloads, people and doctrine for the RAN.

“Technology is changing so quickly, and we don’t want to commit to a great deal of investment and buy enough systems to last us 30 years when the technology will be obsolete in three years,” said Hornsby.

“That’s why we want to buy small, and buy often,” Hornsby said.

Scouting with the Bluefin-12

Testing conducted for the Royal Australian Navy’s SEA 1778 Phase I deployable mine warfare system has been very revealing.

Cmdr. Paul Hornsby is the RAN lead for Autonomous Warfare Systems and is responsible for SEA 1778 PH I, the RAN’s new deployable mine warfare system. Hornsby said Australia has harsh conditions – strong currents and dynamic sea floor conditions—which is especially challenging in mine warfare. “We need systems optimized for our requirement,”

SEA 1778 PH I uses the General Dynamics Mission Systems Bluefin Robotics Bluefin-9 and Bluefin-12 unmanned underwater vehicles (UUVs) with Sonardyne Solstice multi-aperture sonar to find mines. “We’ve tested the Bluefin vehicle with the RAN up in Pittwater, an area to the north of Sydney on the Hawkesbury River, and we’ve had tremendous success,” said Troy Stephen, the director of the Underwater Systems Business for Thales Australia, which is the prime contractor for SEA 1778 PH i. “We used the Bluefin to map the bottom, and we found wrecks that nobody knew about.”

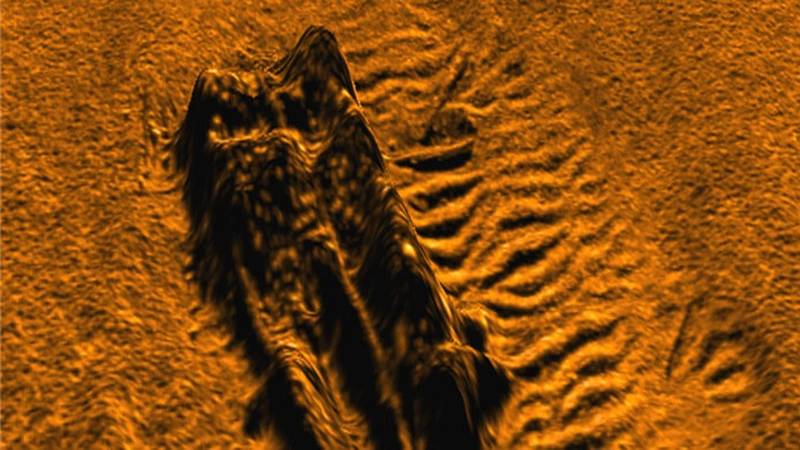

Additional testing was conducted in November 2019 by General Dynamics Mission Systems Bluefin Robotics conducting sea trials of a Bluefin-12 UUV near their facility in Quincy, Massachusetts, captured detailed images of a Navy ship, USS YF-415, lost during World War II. The 132’-foot YF-415 with a crew of 31 was carrying explosives from the Naval Ammunition Depot in Hingham, Mass., on May 10, 1944, when an accidental ignition occurred. The ship was lost with 17 of her crew killed or missing.

“In addition to the shipwrecks our Bluefin UUVs found in Australia, our Bluefin-12 UUV captured detailed images of the USS YF-415 shipwreck during sea trials off the coast near Boston,” said Andy Rogers, vice president of undersea systems at General Dynamics Mission Systems. “Technology advancements for both autonomous underwater vehicles and sensors are allowing new and more detailed surveying of the sea floor in challenging environments. We are better able to locate and image sunken ships, and provide details that can solve mysteries about what happened to them.” Photo: Thales Australia

Photo: Thales Australia