Canadian naval architecture firm Robert Allan Ltd. and Chinese shipbuilder Cheoy Lee Shipyards have rolled out the RAmparts 2500-CL, an exclusive new tug series being built by Cheoy Lee.

The new tug series is an evolution of Robert Allan Ltd.'s RAmparts 2500-W design, updated for Cheoy Lee's marketing objectives, which include increased flexibility allowing for a multitude of options according to clients’ requirements. The first RAmparts 2500-CL vessel is scheduled for delivery in early 2018.

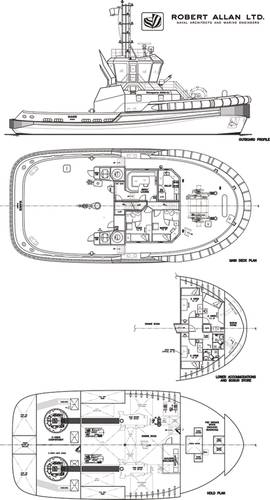

According to Robert Allan Ltd., the hull and skeg of the RAmparts 2500-CL have evolved to provide improved maneuvering and side stepping capabilities. As with all RAmparts series vessels, the hull has been optimized for maximum thrust and bollard pull, while maintaining excellent maneuvering and sea-keeping. A half-raised forecastle deck helps to keep the working deck safe and dry, while a gently rounded deck line in plan to ensure that the tug can safely and easily come alongside and remove itself from an attended ship at speed. The characteristic double chined stern unique to all Robert Allan Ltd. designs ensures that the tug can run astern at high speeds and maintain good control and directional stability.

The tug can be adapted to a suit a wide variety of owner requirements, including:

- Propulsion packages to achieve 50-, 60- and 70-metric-ton bollard pull

- Single or split drum forward winch

- Optional aft winch

- Optional Fi-Fi 1 systems (Fi-Fi 1/2 is standard)

- A variety of MLC compliant accommodation layouts

Particulars of the RAmparts 2500-CL are as follows:

- Length overall: 25.4 m

- Beam, molded: 11.8 m

- Depth, least molded: 4.6 m

- Maximum draft (overall): 4.63-5.1 m

The rule length has been kept less than the 24m loadline and tonnage convention limits while optimizing for maximum hull volume, resulting in improved accommodation spaces and crew comfort.

The vessel has been designed to LR Class requirements with the following notation: LR ✠ 100A1 TUG, ✠ LMC, ✠ UMS, IWS

Tank Capacities at 98 percent are:

- Fuel oil: 91 m³

- Potable water: 11 m³

- Optional foam: 5 m³

- Optional dispersant: 5 m³