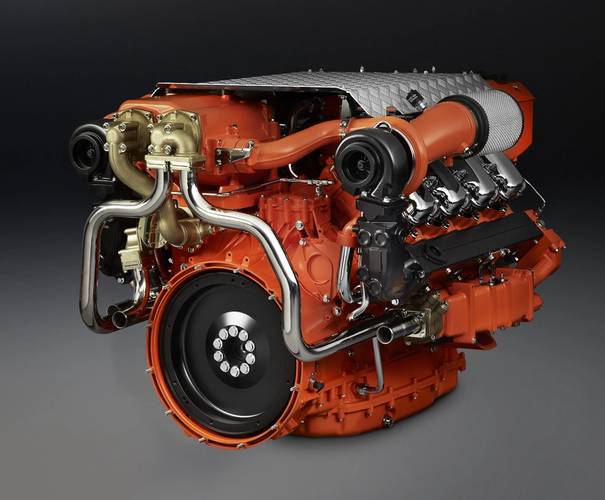

The Scania Marine Engine Solution Showcased at Workboat

Scania introduces a new range of marine propulsion units consisting of engine, transmission and type-approved instrumentation at the International Workboat Show in New Orleans, Louisiana.

The 13-liter marine engines range from 400 hp for continuous use up to 750 hp for patrol craft use.

The Scania marine engine solution, consisting of a new 13-liter marine engine is the first in a new line of engines for propulsion and auxiliary use designed for maximum reliability and durability, as well as low operating cost. Torque ratings have been increased on the new range, making it easier to maintain favorable operating speeds in high sea or with a heavy load. Single-circuit keel cooling is used to simplify installation and reduce cost. The service life of pistons and liners is enhanced by Scania saver ring, a ring placed at the top of the cylinder liner to reduce coke deposits and engine wear.

For marine auxiliary use, the Scania 13-liter engine is designed to handle large step- load variations with short recovery time. The top version achieves its top output of 426 kW at 1,800 r/min. Output has been increased, yet exhaust emissions are low. The engine also features Scania EMS, an in-house developed engine management system that is outstandingly flexible when it comes to tailoring engine performance to individual customer applications.The new 13-liter marine engines complies with emission standards IMO II, EU Stage IIIA and US Tier 2.

New type-approved instrumentation

Scania is also launching a new type-approved instrumentation according to the standards of classification societies such as RINA, DNV, Germanischer Lloyd, American Bureau of Shipping and Lloyd’s Register. The new instrumentation is easily installed and via a user-friendly and flexible web interface, the marine operator can adapt the information on the panels and choose any required data. The panels have prepared layouts for water temperature, engine speed, oil pressure and fuel consumption. The operator can also connect and configure a gauge indicator for transmission monitoring and for fuel or fresh-water levels.

The master panel is equipped with a flexible input/output (I/O) with ten digital inputs, two 4-20 mA inputs, two PT100 inputs and seven digital outputs. The system is expandable with an unlimited number of slave panels via standard Ethernet.

The flexible I/O makes it easy to install surveillance and alerts of seawater flow or fuel consumption. Increased idling makes the maneuvering of a hydraulic pump for powering winches, or cranes, uncomplicated. Connection for throttle availability via all standardized interfaces (0-5 V, 4-20 mA and CAN).

Key characteristics of the new engine range

• Scania PDE unit injector fuel injection

• Revised bore and stroke for increased swept volume

• Increased combustion pressure

• Traditional easy-to-service Scania architecture with individual cylinder heads

• Scania engine management

• Saver ring at the top of the cylinder liners to prevent coke build-up on the piston

Engine architecture

The new engine platform is a completely new design, yet it retains traditional Scania characteristics like individual cylinder heads, camshaft located high in the block and rear-mounted timing gears, as well as the familiar cyclone oil filter. Bore and stroke have been slightly altered and swept volume increased compared to previous Scania engines. Important features for the marine engine segment are reliability, high uptime, generous torque at low revs, good fuel economy and prompt engine response. The cylinder block and other structural components have been redesigned for additional strength. The saver ring at the top of the cylinder liners removes the residual carbon from the edge of the piston crown and reduces cylinder liner wear.

Extended maintenance intervals

Maintenance and oil-change intervals have been extended to 500 hours. Shared components and systems between Scania's different engine series reduce costs for parts stocking and maximizes availability.

In-house development

Scania has secured control of all strategic steps in development and performance control. Basic engine development and manufacturing, as well as the development of engine management, fuel injection and emission control systems are all carried out in- house. This strategy is motivated by demands and targets for performance and fuel economy, as well as to secure consistent environmental performance, robustness and convenience of operation.

Engine weight and dimensions

Engine type

Swept volume

Length

Width

Height

DI13M

775 CI inline 6

59.0 in

37.6 in

42.2 in

Dry weight 2,623.5 lbs with heat exchanger, 2,513.3 Ibs with keel cooling.