Veka-Group Develops LNG Tankers

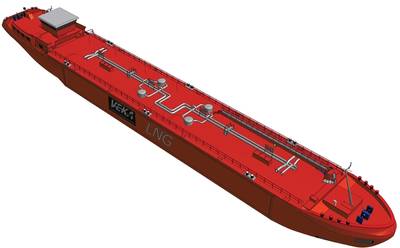

Veka-Group has developed three new LNG tankers, which can also be used as bunker ships.

Two tankers are destined for short sea trips and/or coastal services. The third tanker, a LNG inland waterway bunker ship, is the first of its type in the world. The tanker sails almost completely on the ‘boil off’ of the load and is 100% emission-free. After the introduction of the first bi-fuel tanker in the world, the “Pioneer Knutsen”, this is again a proof of Veka-Group’s innovative power.

With the “Pioneer Knutsen”, Bijlsma Shipyard, member of the Veka-Group, was years ahead of her time. ‘It was the first bi-fuel LNG tanker ever built’, says managing director Arend Bijlsma. ‘Especially for this project we have developed new technology for the storage of LNG and for the use of LNG as fuel for the propulsion engines. The combination of these two techniques made it possible to sail the tanker for a significant part on the ‘boil off’ (the gas that is released by keeping the load on the correct temperature). The engine switches to diesel in case of insufficient ‘boil off’ availability, which explains the term bi-fuel.’ Thanks to these innovations applied when building the “Pioneer Knutsen”, the design received the ‘Clean Marine Award ’ from the European Commission.

Use of ‘boil off’ clean and cost-efficient

‘LNG is a natural gas made liquid by drying, cleaning and cooling it down to -164 ºC’, explains Bijlsma. ‘The LNG stays liquid in special thermally insulated storage tanks. During transport a very small part of the load is released as gas. Before we found a way to use that gas as fuel for the propulsion engine, it was simply flared. The application of the gas as fuel is cost efficient and contributes to the environment.’

Bijlsma expects that the use of LNG by ships for coastal and inland shipping will increase rapidly. ‘Using LNG instead of gas oil gives already now a saving of roughly 25% on your fuel costs. Experts believe that the price of gas oil will reach a level of about € 1.000 per ton in the near future whereas the price of LNG will not or hardly increase. From a financial point of view the use of LNG will be increasingly more attractive. In addition to this the rules with respect to the environmental requirements are becoming stricter in more and more countries. For instance in the Baltic Sea and the Gulf of Bothnia until some years ago it was allowed to use high sulphuric heavy crude. Now only low sulphuric crude is allowed. In the long term the environmental requirements will be tightened worldwide. It is expected that then you will have to use gas oil again or install a scrubber to remove sulfur and hydrates from the exhaust fumes. If you want to sail really clean and cost efficient, LNG is the only answer.’

Small tankers conquer the market

As more ships will use LNG there will be a growing demand for LNG bunker stations and tankers to supply these stations. ‘At this moment there are no small LNG tankers that can supply the LNG from the large terminals to smaller terminals or directly to ships’, says Bijlsma. ‘Last year a LNG ship moored for the very first time in Rotterdam and more will certainly follow. In the short term there will be a bigger market for small tankers. We want to be a pioneer in this field and therefore we started with the development of the LNG short sea tanker and the LNG – Oil Combi tanker.’

Both ships are equipped with a dual fuel engine. ‘The engine runs for about 25 percent on the ‘boil off’ and for the rest on the own LNG cargo’, explains Bijlsma. ‘Because the engine can also run on diesel a 1 percent diesel injection is used. The tankers are almost free of hazardous emissions. In case a LNG engine is installed it will be 100% hazardous emissions free. ’

Inland bunker tanker sails on ‘boil off’

This is already the case with the LNG inland shipping bunker tanker. ‘The 100 percent LNG engine burns the ‘boil off’ completely’, explains Veka project manager Robin Sijbrands. ‘The advantage of these engines is that with respect to the output they perform better than dual fuel engines. Therefore only a very limited quantity of the LNG cargo is required for fuel consumption.’ This tanker is so innovative that the design has been submitted for approval to the Central Commission for Navigation on the Rhine in Strasbourg and to the Maritime Safety Committee (AND) of the United Nations Economic Commission for Europe (UNECE). ‘The results of the carried out risk assessments are very positive. The hull has already been completed. As soon as the plans have been approved we will immediately proceed with the construction and completion of this tanker.’ The LNG inland shipping bunker tanker is expected to be put into service late 2013.

LNG inland shipping container ship

Around the same period also a LNG inland shipping container ship will be delivered. ‘This ship, equipped with 100 percent gas engines, will be deployed for the route Rotterdam – Duisburg’, says Sijbrands. ‘It will be provided with two LNG tanks each having a capacity of 40 cubic meters.’ This ship is, like the LNG inland shipping bunker tanker, the first of its type in the world. ‘We have developed a system that enables the ship in port to run the electrical network on board completely on batteries. This results in a situation of zero pollution, which is really unique. With additional battery sets the ship can sail using electric power only.’ Practically gas engines require much less maintenance than diesel engines. ‘You can sail much longer before engine overhaul is required.’

Sijbrands expects that this concept will quickly catch on in the market. ‘Especially for longer distances, the use of such a ship is profitable. We are sure that this ship, like the LNG inland shipping bunker tanker, will be another success for Veka-Group.’