Exploring 'Future Fuels' - Methanol’s Superstorage Solution

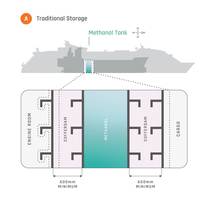

Technical inquiries to SRC Group ramped up after it received Approval in Principle (AIP) for a concept which ‘reinvented methanol fuel storage’ on board ships. Delivering the answers has seen technical talk converting into project discussions ‘Green’ methanol has the ability to one day run vessels almost emission-free, and commercial shipping increasingly investigates. Derived today principally from natural gas, methanol is nonetheless available, relatively easy to handle and predictable.

PPG Rolls Out New Tank Coating

PPG has lunched a new phenolic epoxy tank lining, PPG Phenguard 985, geared for the marine and tank storage sectors. The tank lining is designed to deliver high chemical resistance to a wide range of aggressive chemicals and higher temperature resistance for chemicals that contain fatty acids.“The latest addition to our PPG Phenguard range, PPG Phenguard 985 tank lining features a patent-pending formulation that can be applied in two or three coats instead of the traditional three coats without compromising chemical resistance…

Prysmian Wins SGRE Gig

Italian cable manufacture Prysmian Group has secured a contract with turbine manufacturer Siemens Gamesa Renewable Energy (SGRE).The scope covers low voltage cables and assemblies for nacelles and low voltage cables for towers, Prysmian said. The deal also includes fully-terminated medium voltage assemblies for towers, it added.The supply includes products and services from Prysmian Group’s wind portfolio of low voltage cables and assemblies for nacelle platforms, low voltage cables for towers and fully terminated medium voltage assemblies for towers, well renowned to be specifically designed and optimized to work with high torsion,…

Ship Paint: NRL Pigment Package Slows Discoloration

A pigment package designed by the U.S. Naval Research Laboratory (NRL) to slow discoloration of the exterior coating on surface ships has started to make its way into the fleet and is producing early, positive results.NRL researchers created the pigment combination to satisfy the fleet requirement for the Navy standard "haze gray" paint that will remain color stable for longer than current coatings. While many paint manufacturers had produced new coating technologies that solved a variety of other problems…

Chemical Tankers Market to Grow at a CAGR of 4.5% by 2022

The chemical tankers market is projected to grow from USD 26.63 billion in 2017 to USD 33.11 billion by 2022, at a CAGR of 4.5% between 2017 and 2022, said a research report. The flourishing chemical industry and increasing use of water transportation for transferring chemicals from one place to another across the globe are the major driving factors for the growth of the chemical tankers market, said Report Linker. Chemical tankers market includes revenues earned through shipping of chemicals and related products. The growth of the chemical tankers market is expected to be adversely impacted by the political unrest in the Middle East & Africa region as this region is one of the leading markets for chemical tankers.

Keeping a Tight Lid on Tier III & Sealing Solutions

With more than 90 percent of global trade carried by sea, shipping is a major battleground in the reduction of emissions. Tier III is the latest emission standard pertaining to NOx emissions from marine diesel engines. Tier IV is expected to come into effect for 2020 – with engine manufacturers already seeking sealing components to future-proof engines well into the next decade. Here we explore challenges faced by diesel engine operators in the face of Tier III, and how the correct selection of sealing materials could deliver better performing solutions.

Cast Polyurethane for High Impact, High Wear Applications

Although ship and boat building design engineers have traditionally specified parts made of rubber, plastic or steel when durability is required, many are considering cast polyurethanes as a new alternative for demanding, high-wear, abrasion and impact applications. Cast polyurethanes, also broadly referred to as urethanes, are tough, elastic materials that combine many of the performance advantages of high-tech plastics, metals and ceramics along with the resiliency and flexibility of rubber parts and are ideal for ship/boat building components.

AkzoNobel Expands Coatings Research Facility

AkzoNobel has completed the $3.5 million expansion of its U.S. research and development facilities in Houston. Carried out in phases over a period of three years, the investment in the site – which employs around 40 scientists – will support the company’s Protective Coatings, Marine Coatings and Specialty Coatings businesses. Part of AkzoNobel’s ongoing investments in its global RD&I activities, the Houston upgrade follows an investment of $ 14.2 million in a research and innovation hub in Felling, U.K., announced earlier this year.

PPG Debuts New Coatings for Steel, Metal Applications

PPG has introduced PSX 800 and PSX 805 coatings for steel and metal surfaces, two next-generation products formulated with greater flexibility and hiding performance than competing polysiloxane coatings. According to PPG, the two new products feature improved flexibility, which enables them to withstand the cracking under stress commonly associated with difficult steel, tank exterior and building exterior applications. PSX 805 coating adds a durable satin-sheen finish that masks imperfections on metal surfaces.

PPG Unveils New Coating for Dry Bulk Cargo Holds

Debuting its latest offering at Posidonia 2016, PPG’s protective and marine coatings business has unveiled a new protective system for dry bulk carrier cargo holds: the PPG SIGMASHIELD MTC system, built on coating technology that comprises a PPG SIGMASHIELD PRIME undercoat and PPG SIGMASHIELD MTC topcoat. Designed specifically for the cargo holds of dry bulk carriers, the system’s chemistry maximizes technical performance and offers a commercially sound solution for spot and full repairs as well as for application at newbuild, PPG said.

Pontoon Deck Preservation for Floating Dry Docks

Dry dock pontoon deck preservation is often taken for granted. In the flow of ever changing priorities for dry docks, it often gets pushed aside and/or delayed. If neglected long enough and often enough between preservation cycles, the thickness of the pontoon deck steel plates can be compromised. Salt water with chloride contamination causes accelerated corrosion while impact and abrasion damage from heavy equipment also take their toll. For shipyards, the overall objective should be to provide a protective surface that will hold up over time, and that is easy to clean.

RS Approves Composite Tank Containers

Russian Maritime Register of Shipping (RS) has issued Certificates of approval for tank containers made of polymer composite materials (PCM) intended for transportation of aggressive media. The manufacturers of tank containers are JSC “Research and production corporation UralVagonZavod” / Uralcryomash JSC. Issuance of RS documents is a logical end of one and a half year activity of a group consisting of specialists from JSC “Research and production corporation UralVagonZavod” / Uralcryomash JSC where a series production of PCM containers is expected to be commenced, “STTC ApATech-Dubna” ltd. which is responsible for design of material and structure, Spectransgarant LLC - tank container company-operator and RS.

New Tank Coating from Hempel

Marine paints manufacturer Hempel announced the launch of a new pure epoxy tank coating, Hempadur 15460, to replace its Hempadur 15400 tank coating. Hempadur 15460 is designed specifically as a tank coating for chemical vessels and is based on amine adduct cured epoxy technology, which the manufacturer says delivers resistance to continuous immersion in a range of chemicals, including crude oil up to temperatures of 80ºC/176ºF. The coating uses no toxic products and can be used to coat all liquid cargo tanks. It is also suitable for grey and black water tanks, mud and brine tanks, refrigerated seawater fish tanks and other vessel tanks.

PPG Unveils Phenguard Pro Tank Coating

PPG Protective and Marine Coatings has unveiled Phenguard Pro, a tank coating system that is intended to offer benefits for both shipyards and ship-owners. For shipyards and at installation, the coating system provides potential efficiency gains of over 20 percent compared to three-layer coating systems, PPG said. For owners it provides the wide chemical resistance and long carriage time of more than 3,400 cargoes, delivering maximum flexibility to the product tanker trades, according to the manufacturer.

MN 100: PPG Protective & Marine Coatings

Executive Vice President: Viktor R. Vice President: Timothy M. PPG Industries, Inc., headquartered in Pittsburgh, Pennsylvania, USA, is a global, multi-billion dollar diversified manufacturer supplying paints, coatings, chemicals, optical products, specialty materials and glass. PPG is a world leader in protective and marine coatings, developing products that protect customers’ assets in some of the world’s most demanding conditions and environments. These include, among others, Offshore, Petrochemical, Marine new-build, Marine dry dock and Marine sea stock.

Adances in Marine Coatings & Corrosion Control

The advance of modern marine coatings and related technologies is not unlike other technical sectors of the maritime industry, primarily driven by emerging regulation from the international, national and regional level, usually in regard to environmental concern. But in recent years, an increased focus on the reduction of marine emissions in tandem with the capability to more directly correlate clean, well-maintained hulls with reduced fuel consumption and lower emissions has driven the industry further faster…

Marine Manufacturer Says Thermoplastic Pipes Eco-friendly

GF Piping Systems say their plastic piping provides better efficiency and lower weight compared to traditional piping materials. Thermoplastic plastic piping represents an environmental friendly solution thanks to a carbon footprint that is 5 times lower than metal. Applications such as Inert Gas Cleaning (Scrubbing), Advanced Water Treatment, Ballast Water Management, Laundries supply and drainage, and Air Conditioning can all benefit from plastic piping. For scrubber installations…

LVDT Linear Position Sensors Perform in Hostile Environments

LVDT Linear Position Sensors Available in Different Housings to Perform in Hostile Chemical, Radiation and Seawater Environments. Macro Sensors (www.macrosensors.com) offers its AC-operated LVDTs in different material housings to perform in varying operating environments including those with high and low temperature extremes, radiation exposure, seawater and vacuum pressure conditions. Standard configurations of Macro Sensors’ AC-operated linear position sensors are constructed…

Sigma Adds to its Coatings Line

As an acknowledged industry leader in Marine tank coating technology Sigma Coatings has added another groundbreaking product to its assortment which already includes Sigma Phenguard and Sigmaguard CSF. After successful use in non-marine applications such as land based storage tanks, Sigma Coatings has just launched the solvent free epoxy phenolic tank coating Sigma Novaguard for Marine applications. Sigma Novaguard has increased chemical resistance versus Pure Epoxy and standard Solvent Free Epoxy tank coatings currently on the market whilst possessing the same excellent flow and edge coverage properties of the Sigma solvent free product range.

New Antennas from Sea Tel

Sea Tel has released the first USAT (Ultra Small Aperture Terminal) antenna. Sea Tel announced a smaller, lighter 60 cm antenna system, the first 60 cm marine antenna to meet FCC’s and ETSI’s specification allowing multi mode use with Spread Spectrum, TDMA and SCPC services. The USAT 24 is aimed at Coastal trading vessels and inland craft. Services are currently being Beta trialed with a number of modem providers including Hughes, Viasat, iDirect, and STM on a number of satellite operator’s footprints world-wide. Service in Europe and the US is expected to start in the 4th Quarter of 2008.