Fincantieri Marinette Marine Dedicates New Blast and Paint Facility

Fincantieri Marinette Marine dedicated its new blast and paint facility in Marinette, Wis. on December 5, 2023.Fincantieri CEO Pierroberto Folgiero and Wisconsin Governor Tony Evers were present to help cut the ribbon on the new facility where shipbuilders will efficiently prepare and paint large portions of Constellation-class frigates prior to final construction. Fincantieri Marinette Marine is on contract to build the lead ship and three additional vessels, with additional options for six more frigates.The 25,000 sq.ft.

Austal USA Opens New Steel Facility

Mobile, Ala. shipbuilder Austal USA hosted a ceremony to celebrate the opening of its new facility which adds steel shipbuilding capability to the company’s well-established aluminum shipbuilding expertise.“We are so excited to see our plans to add steel to our capabilities come to fruition,” said Austal USA President Rusty Murdaugh. “The addition of steel capability is a game changer as it opens up our capability to support the U.S. Navy, U.S. Coast Guard and other customers with high-quality ships.

Shipbuilding: Fincantieri Marine Group Invests Mightily to Deliver for the US Navy

When he served as the commander of NWSC Carderock, Mark Vandroff woke every morning knowing that his counterpart in China had just gone to bed and had spent that day trying to make China’s Navy superior. His job, he figured, was to “get cracking and work to make our Navy even better.” Now the CEO at Fincantieri Marinette Marine (FMM), Vandroff brings that passion for navy shipbuilding – and delivering on the new USN Constellation-class frigates contract – to work every day.Introducing a new class of warship usually comes with a heaping helping of pain, from cost overruns to technical glitches.

U.S. Navy: Constellation-class Brings Frigates Back to the U.S. Fleet

Introducing a new class of warship can be fraught with pain, and the first ship is always the hardest – almost always behind schedule and over budget. And trying something new and transformational is even harder.The U.S. Navy knows this from experience. That’s one reason why the Navy is opting for a lower risk design for its next class of guided missile frigates (FFGs).Just about every new class has experienced a rough start. Although the USS Arleigh Burke-class of guided missile destroyers (DDGs) today represent the largest and most successful class of warships…

Better Blasting: Send in the Robots

When designing and constructing a new blast and paint facility at its yard in Belle Chasse, La., C&C Marine and Repair set out to create a safe, efficient and environmentally friendly worksite that would deliver a high-quality product.Fifteen months and 131 barges later, C&C Marine has nearly doubled its capacity as the facility and its robotic blasting technology continually meet and exceed expectations, says Tony Cibilich, president and owner of C&C Marine and Repair, who sees a long list of benefits for customers…

C&C Marine Celebrates 100th Barge Blasted

Just nine months after opening their new Robotic Paint and Blasting facility C&C Marine and Repair has announced the blasting of its 100th barge. “We knew we had the capability to blast and paint barges quickly and efficiently, but what we’ve been able to accomplish in these first nine months has exceeded our expectations in both speed and quality of blast” says C&C Marine and Repair’s owner, Tony Cibilich. The 83,350 square foot facility can accommodate barges up to 320’x75’ and has the capability to blast and paint a standard 30…

Shipbuilding Interview: Ron Baczkowski, VT Halter

VT Halter in Pascagoula, MS has been on a strong run, capped by its winning the high-profile contract to build the U.S. Coast Guard’s next generation of icebreakers. Maritime Reporter recently spoke with Ron Baczkowski, President and CEO, VT Halter Marine, for insights on the shipyard’s recent success and future prospects. Globally, the shipbuilding industry has gone through some ‘interesting’ times of late. How has it looked from your perspective?The shipbuilding market and activity at VT Halter during the past 12 months has been dynamic.

Shipyard Coatings: Green is the Best Color

VT Halter’s new state-of-the-art blast and paint facility, already paying dividends for the shipyard’s bottom line and the environment alike, is poised to lift your bottom line with improved coatings and reduced corrosion.When it comes to marine coatings, preparation is everything. If that’s the case, then Gulf Coast-based VT Halter has all the boxes checked when it come to making sure that every vessel component and exposed surface that leaves its facility is ready for whatever harsh conditions come next. That’s because, in April of 2018, VT Halter Marine unveiled a state-of-the-art blast and paint facility that today allow ship sections to be prepared, blasted and painted in a controlled environment.

New Indoor Paint and Robotic Barge Blasting Facility

LA based C&C Marine and Repair has announced the opening of their new indoor, climate controlled, Paint and Blast Facility. The 83,350 square foot facility can accommodate barges up to 320’x75’x20’ and will be able to blast and paint a standard 30,000 Barrel Tank Barge or two 10,000 Barrel Tank Barges in 7-10 days. The fully enclosed, climate-controlled facility is unaffected by inclement weather and allows for uninterrupted operation year round. “We modified technology that was being used to blast rail cars and containers and have successfully adapted the process to blast barges…

VT Halter Opens New Paint Facility

VT Halter Marine Inc. has unveiled its new state-of-the-art blast and paint facility that will allow ship sections to be prepared, blasted and painted in a controlled environment. The ceremony included a keynote speech given by Senator Roger Wicker, U.S. Senator for the state of Mississippi.“The installation of this new blast and paint facility is to incorporate cutting-edge technologies in our marine construction programs. We are now able to apply a diverse range of protective coatings regardless of the weather conditions…

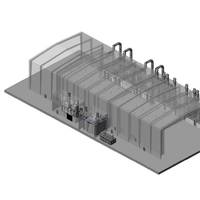

VT Halter Building New Blast and Paint Facility

VT Systems’ shipbuilding arm VT Halter Marine said it has begun construction of a new state of the art integrated blast and paint facility, effective April 17, 2017. The new facility at VT Halter’s Pascagoula, Miss. shipyard will allow the complete indoor and environmentally controlled surface preparation and final painting of ship sections prior to final erection. Its “flow-thru” configuration will allow ship sections to be prepared, blasted and painted complete without having to be taken outside and ensuring particles from the facility are not released into the environment.

NASSCO Invests in Facilities, Equipment and People

General Dynamics NASSCO has invested several hundred million in capital projects as part of its efforts to increase efficiencies via modular shipbuilding, including: two 300-ton cranes allowing shipbuilders the ability to increase the size of the erectable blocks; a block assembly line to optimize construction of commercial ship blocks; inverted block and grand block outfit areas to more fully install components and equipment on blocks; and a state-of the-art, environmentally-friendly blast and paint facility to paint blocks indoors with high capacity equipment.

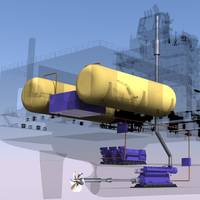

TOTE Goes Gas

Last month U.S. ship owner Tote Inc. shocked the maritime community in ordering the world’s first LNG-powered containerships; in one fell swoop energizing the U.S. shipbuilding sector. On the occasion of this historic contract, top executives from TOTE, NASSCO and MAN spoke to Maritime Reporter & Engineering News to weigh in on the deal’s significance. In recent decades, particularly in the large commercial ship niche, it is fair to say that the U.S. has not been a world force.

Venture Boat Co. Relaunches Itself on Market

Under leadership of new owner, Lee Heaton, US-based Venture Boat Company features modernized new additions to its range. Venture Boat Company has undergone a complete modernization, adding a number of innovative improvements to their existing models, introducing new models and moving production to the world-famous American Custom Yachts (ACY) facility in Stuart, Florida. Through their new partnership with American Custom Yachts, Venture Boats is not only able to provide customers…

Australia Invests in Shipbuilding

The expansion of Western Australia’s shipbuilding capabilities is set to continue with the construction of two crucial common-use facilities at the Australian Marine Complex (AMC) at Henderson. The State Government has today called for expressions of interest to build a service and repair facility for the local super-yacht industry and a blast and paint facility at the AMC. Industry and Enterprise Minister Francis Logan said the State Government was committed to ensuring the long-term future of the WA shipbuilding industry by planning for these new facilities. Logan said the super-yacht industry had the potential to bring millions of dollars to Western Australia.

Expansion Continues at the Australian Marine Complex

The expansion of Western Australia’s shipbuilding capabilities is set to continue with the construction of two crucial common-use facilities at the Australian Marine Complex ( AMC ) at Henderson. The State Government has today called for expressions of interest to build a service and repair facility for the local super-yacht industry and a blast and paint facility at the AMC. Industry and Enterprise Minister Francis Logan said the State Government was committed to ensuring the long-term future of the WA shipbuilding industry by planning for these new facilities. Source: Press Zoom