ABS AIP for "Sterntube-less" Ship

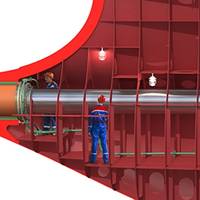

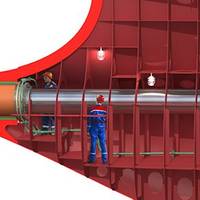

Thordon Bearings said ABS issued an Approval in Principle to the “sterntube-less ship” concept developed in cooperation with the Shanghai Merchant Ship Design & Research Institute (SDARI), the National Technical University of Athens (NTUA) and Thordon Bearings Inc.The design replaces a vessel’s sterntube with an irregular shaped chamber that allows a shorter, water-lubricated propeller shaft to be inspected and maintained while the vessel is afloat, without having to withdraw…

ABS Grants AIP to SDARI for Approach to Stern Tube Design

ABS has granted Approval in Principle (AIP) to the Shanghai Merchant Ship Design and Research Institute (SDARI) for its vessel design with a novel aft layout, which eliminates pollution and promotes efficient vessel operations.The SDARI design, developed in cooperation with Thordon Bearings Inc. and the National Technical University of Athens (NTUA), introduces a new approach to the vessel’s aft layout, including removal of the stern tube casting, employing seawater for lubrication…

Maritime Reporter TV: Interview with Anna Galoni, CEO of Thordon Bearings

Maritime Reporter TV's Greg Trauthwein has interviewed Anna Galoni, the recently appointed chief executive officer (CEO) of Thordon Bearings Inc., a Thomson-Gordon Group company.Galoni joined the Burlington, Ontario-headquartered company in 2007 after graduating from Queens University with a Masters’ Degree in epidemiology.

Galoni Named CEO of Thordon Bearings

Anna Galoni was appointed chief executive officer (CEO) of Thordon Bearings Inc., a Thomson-Gordon Group company.Galoni joined the Burlington, Ontario-headquartered company in 2007 after graduating from Queens University with a Masters’ Degree in epidemiology. Prior to her appointment in April, she held a number of senior roles in various departments including human resources director, new product development director and, subsequently, chair, Thordon Bearings, a position she continues to hold.Her appointment follows the retirement of Terry McGowan…

MN100: Thordon Bearings Inc.

A perennial fixture in our prestigious MN100 edition - MarineNews' annual look at the best 100 individuals and firms in the shallow draft, brown water and workboat sectors - Thordon Bearings has been on the leading edge of environmental improvements for the marine industry for many years. The Case:Thordon has invested heavily in the inland waterway market, keeping two warehouses well stocked with tailshaft bearings, seals and rudder bearings to ensure quick delivery. The TG100…

Polymer Pioneer Wins Sperry Award

Thordon Bearings’ founder and polymer materials pioneer George A. (Sandy) Thomson has been awarded the global transportation sector’s most distinguished accolade, the Elmer A. Sperry Award 2019 for “Advancing the Art of Transportation”.Thomson joins a long list of Sperry Award recipients, which was established in 1955, including Donald Douglas, Ferdinand Porsche, Sir Geoffrey De Havilland, Christopher Cockerell, Leonard Hobbs, Perry Pratt, Josef Becker and Malcom McLean.“I am deeply honored and humbled to win this award…

Thordon Bearings, Heddle Marine Partner for Propeller Shaft Conversions

Thordon Bearings Inc. and Heddle Marine Service Inc. have signed a cooperative agreement under which the Canada-based ship repair company will work together with Thordon Bearings Inc. to promote the conversion of ships’ oil lubricated propeller shafts to Thordon’s COMPAC open seawater lubricated bearing system.The agreement will create an action plan in which a specialist team, comprised of Heddle Marine and Thordon Bearings’ personnel, to offer support to ship managers and owners…

Thordon, DDW-D Partner for Shaft Line Conversions

Thordon Bearings and Drydocks World-Dubai (DDW-D) have signed an agreement under which the UAE-based shipyard will work together with Thordon Bearings Inc. to promote the conversion of ships’ oil lubricated propeller shafts to Thordon’s COMPAC open seawater lubricated bearing system. The agreement will create an action plan in which a specialist team, comprised of Drydocks World-Dubai and Thordon Bearings’ personnel, offer support to ship managers and owners looking to ensure…

SNAME Honors Thordon's Sandy Thomson

At the opening session of the 2016 SNAME Maritime Convention in Bellevue, Washington, George A. (Sandy) Thomson was elected a Fellow of the Society of Naval Architects and Marine Engineers (SNAME). This is quite an honor for Thomson who has a long family history in the maritime industry. Thomson’s great, great grandfather was a deep sea captain sailing the Great Lakes before becoming a lighthouse keeper; his uncle was head of Shell Canada when Shell maintained a fleet of steam powered tankers operating on the Great Lakes…

Thordon Bearings Names New China Distributor

Thordon Bearings Inc. of Canada announced that CY Engineering Co. Ltd. will take over as the new authorized distributor for the People’s Republic of China, including Macau and Hong Kong, effective August 28, 2015. With this agreement, CY Engineering becomes Thordon’s stocking distributor for manufacturer of nonmetallic marine bearing systems. A company with over 25 years’ experience in seawater lubricated propeller shaft bearing systems, Thordon Bearings designs and manufactures a complete range of nonmetallic sleeve bearing solutions for marine…

‘Seawater is the Ultimate EAL’

Thordon Bearings Inc., a manufacturer of seawater lubricated bearings for the global marine industry, has questioned the rise of environmentally acceptable lubricants (EALs) in oil-based stern tube seals and bearings, stating the industry can use “the most environmentally safe lubricant” there is: seawater. The U.S. Environmental Protection Agency (EPA) is enforcing regulations introduced in December 2013 that stipulate that all vessels over 24 meters in length operating in U.S. waters must switch over to EALs in all oil-to-sea interfaces before their next drydocking.

Partnership Promotes Seawater Lubrication

Thordon Bearings Inc. signed a letter of intent (LOI) under which it will cooperate with MSR Gryfia of Poland to promote the conversion of ships to an open seawater lubricated propeller shaft Thordon bearing system from a sealed oil lubricated propeller shaft bearing system. The LOI will create an action plan in which a Ship Conversion Team, comprised of MSR Gryfia and Thordon Bearings representatives, that promotes this initiative to the marine community. The goal of this movement…

MN 100: Thordon Bearings Inc.

Thordon Bearings Inc. designs and manufactures a complete range of polymer bearing and shaft line products for the marine, clean power generation, pump, offshore and industrial markets. Thordon’s strong and recognizable global brand is known for high quality and superior performance, eliminating oil and grease from bearing applications in ships, hydro-turbines, vertical pumps and many other applications. New ideas from the field are brought to New Product Development, who continually evaluate new polymers, products and application designs.

Cutterhead Shaft Bearings Last 9 Years on Dredger

Water lubricated Thordon Composite cutterhead shaft bearings have performed well for nine years on one of the largest cutter suction dredgers in the world–Dredging, Environmental and Marine Engineering N.V. (DEME)’s D'Artagnan (28,200 kW total installed power). The vessel had a major dry docking at Drydocks World-Dubai in February 2014 where the shaft was removed, and bearings and shaft inspected. Originally built in 2005, the D'Artagnanself-propelled cutter suction dredgeris involved in very heavy rock-breaking having a cutting power for operations in rock soils of 6000 kW.

Shaw Joins Capilano Maritime Design

Capilano Maritime Design Ltd., a naval architecture design firm based in North Vancouver, BC, Canada, announced that John Shaw has joined the firm as Manager of Engineering. For the last six years, John was employed at Seaspan Shipyards where he played a role in the shipyard’s successful bid for a $2.6 billion contract for the construction of several non‐combat ships for the Government of Canada. He has served as Technical Director for Thordon Bearings Inc. for many years during the development of their highly successful water‐lubricated bearing products.

Don’t Forget: Seawater is a Free EAL

If your vessel is trading in U.S. waters, you need to be aware of the new oil to sea interface law that comes into effect on Dec. 19, 2013. According to the new U.S. Environment Protection Agency Vessel General Permit (VGP), all vessels built on or after Dec. 19, 2013, must use an environmentally acceptable lubricant (EAL) in all oil to sea interfaces. For all vessels built before this date, unless technically not feasible, ship owners must use an EAL in all oil to sea interfaces. Additional information on the EPA’s VGP can be found at http://cfpub.epa.gov/npdes/vessels/vgpermit.cfm#final.

Thordon Receives Ocean Exchange Industry Challenge Award

Thordon Bearings Inc. received this year’s Industry Excellence Award at the third annual Ocean Exchange on Sunday, September 29, 2013 at the Savannah International Trade & Convention Center in Savannah, Georgia. Recognized for eliminating oil discharges from commercial ships using seawater lubricated propeller shaft bearings, Thordon was one of three international recipients of the award. The Industry Excellence Awards recognize and honor corporations and organizations implementing tangible solutions that shape the future today.

New Thorplas-Blue Bearings on the Market

Thordon Bearings Inc. has launched the newest addition to their grease‐free polymer lineup: ThorPlas‐Blue. The lifetime lubricated bearing formula is capable of operating pressures up to 45MPa (6,527 psi) and can be easily back‐fit into virtually all deck machinery applications where greased bronze is currently installed. ThorPlas‐Blue was developed as a maintenance‐free solution to replaced greased bronze bearings as well as eliminate a source of pollution. Deck machinery and steering gear bearings require frequent maintenance and grease lubrication.

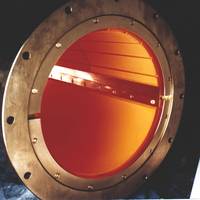

New Mechanical Shaft Seal from Thordon

Thordon Bearings Inc., a company in grease and oil-free bearing solutions announced the introduction of TG100, a new water lubricated mechanical face seal for 100-305 mm (4-12”) shaft diameters specifically designed for operation in abrasive waters, but can operate in clean water as well. The TG100 uses Silicon Carbide seal faces designed to last the life of the vessel and operate in both clean and abrasive-laden waters. If the face seals should ever experience damage, a feature…

Thordon Appoints New Regional Manager

Sam Williams was appointed Regional Manager for China, Korea, Japan, Taiwan and Vietnam for Thordon Bearings, INc. The position is effective from May 1. www.thordonbearings.com

Carisbrooke Shipping Chooses Thordon Bearings

Eco-conscious Carisbrooke opts for seawater lubricated propeller shaft bearings on latest newbuildings. The Vectis Eagle, an 8500 dwt multi-purpose dry cargo vessel, is Carisbrooke Shipping’s latest newbuild and first of their fleet to be fitted with Thordon COMPAC seawater lubricated propeller shaft bearings. The Finnish/Swedish 1A Ice-Class vessel launched in September 2011 and is currently carrying out its maiden voyage through the Panama Canal travelling from China to Haiti and Brazil.

Thordon Appoints Western Europe Sales Manager

Sixteen –year veteran, George Morrison has been appointed the Area Sales Manager for Western Europe replacing retiring Campbell Cunningham. According to Thordon’s Commercial Director, Jan Willem de Jong, George’s experience and energy will be a catalyst for maintaining our strong growth in Western Europe. “George is the perfect leader to develop our existing and new products with our strong distribution network”, said de Jong. “He brings a wealth of bearing and seals experience combined with sales…

Thordon Bearings Appoints Mill Log Marine Distributors

Mill Log Marine of Burnaby, B.C. has been appointed the authorized Distributor in British Columbia for Canadian manufacturer, Thordon Bearings replacing W.L. Marine. With this agreement, Mill Log Marine becomes the stocking distributor for the world’s largest manufacturer of non-metallic oil and grease free bearing systems. “Mill Log Marine’s reputation, expertise and knowledge of the marine market gives us great confidence in knowing that our products will be strongly supported in western Canada”, added Jan Willem de Jong, Commercial Director, Thordon Bearings Inc. Don Lindsey, Director of Sales & Marketing for Mill Log Marine stated: “Thordon Bearings Inc. Thordon Bearings Inc.