New Propeller Optimization Process Can Analyze 10,000 Designs a Day

A newly developed propeller optimizer makes it much faster to identify propeller-hull reactions and reach design decisions.

In the EU project STREAMLINE the fuel efficiency of a chemical tanker was improved by optimizing the hull form and propeller. To this end, MARIN used its hull optimization program PARNASSOS EXPLORER and a newly developed propeller optimizer. The hull form itself was optimized for low resistance and for having a wake field as rotationally symmetric as possible, while simultaneously maintaining the displacement and sufficient space for the engine room. Meanwhile, the propeller was required to deliver the right thrust at the same ship speed and engine rate of revolutions.

Normally, the propeller designer starts when the hull lines have been set and the main propeller parameters have been decided upon.

These parameters follow from series analysis, such as the Wageningen B-Series, plus hands-on experience and rules of thumb to estimate the effect of propeller-hull interaction. For instance, the sector knows that the best propeller diameter in a wake field is smaller than given by the propeller series. Once the main dimensions are selected, the designer continues to mold the geometry until the efficiency is high and the hindrance from cavitation is as low as possible. This is a time-consuming process that is particularly ill-suited to finding the best propeller when considering 500 hull form variations can be generated, as was the case here. It was clear that a tool that can quickly cover a wide range of design choices and return ballpark figures for efficiency, including the propeller-hull interaction effects, was required.

When a large number of propeller geometries are to be generated, the range should be as large as possible but certainly not by including every imaginable shape.

Therefore, the propeller blade geometry was built up from radial distributions for the pitch, chord length, skew, rake, camber and thickness, and these distributions were described by newly developed parametric functions.

In order to remain close to the shape of real propellers, MARIN analyzed more than 1,200 unique propeller designs in its database and used the results to train the parameters. Not only could the majority of propellers be well captured, the generation of a new blade by randomly changing the parameter values nearly always resulted in a plausible blade outline.

Avoiding the Generation of Unsuitable Propellers

Naturally, the proof of the propeller is in the computing. For STREAMLINE, all propeller geometries were analyzed with MARIN’s Boundary-Element Method PROCAL. Although each propeller was unique, differing in blade shape as well as blade area ratio, diameter or blade number, they all generated the same thrust at the same ship speed and shaft rate of revolutions by automatically adapting the effective pitch. This last requirement avoids the generation of ‘trivial’ propellers that operate at a lower rate of revolutions and nearly always have a better efficiency, masking the effect of improved blade design and introducing a bias in the comparison.

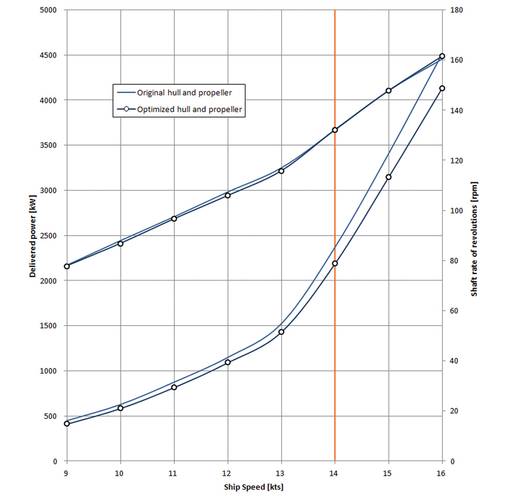

Using MARIN’s computer cluster, it was possible to generate and analyze more than 10,000 new designs per day. The best propeller-hull combination was tested for its performance by model scale tests: a 7.5% power reduction at the design speed was identified and the shaft rate of revolutions did not change. This improvement is attributed to a reduction in resistance, an improvement in propeller-hull interaction by a lower propeller loading due to both the lower thrust requirement and a larger propeller diameter, and lastly, an increase in propeller efficiency by an optimized loading distribution in the wake of the ship.

The propeller optimization procedure can quickly show the relations between all the parameters and propulsion efficiency for a given wake field of a ship. But not only did MARIN find an optimum loading distribution and diameter, it also knew how much skew to apply to reduce thrust loading fluctuations. When results of the optimization with a given propeller design are compared, it is possible to see how much its efficiency can improve and which parameters to tune.

Now that this first test case has been performed, MARIN is continuing to explore the automated propeller design. The process will be sped up by the use of genetic algorithms and integrated into the daily design process. The EU project SONIC already presents the next challenge: optimizing for both high efficiency, as well as low radiated noise.

References: Foeth, E.J. & Lafeber, F.H., Systematic propeller optimization using an unsteady Boundary-Element Method, 12th Int. Sym. Practical Design of Ships and Other Floating Structures, Korea, 2013.

The Author

Evert-Jan Foeth is researcher Propulsion & Cavitation at the R&D department of MARIN, the Maritime Research Institute Netherlands. MARIN offers simulation, model testing, full-scale measurements and training programmes, to the shipbuilding and offshore industry and governments.

[email protected]

(As published in the March 2014 edition of Maritime Reporter & Engineering News - www.marinelink.com)