The Hour of Power

Hybrid Marine Technology and Green Ports

In 2015 two significant developments are going to make many operators, owners and builders of professional vessels consider hybrid marine power. First, the new emissions laws in ports and second, there is now an incentive for high technology manufacturers to invest in developing highly efficient batteries.

Hybrid is ‘here and now’ technology that is being utilized by many industries around the world. The marine industry is now recognizng the potential of utilizing hybrid power and innovative propulsion systems for vessels in the sub IMO / sub 24 meter (80 feet) professional sector.

‘The Hour Of Power’ has been well received by the marine industry worldwide. This simple concept enables vessels to run in and out of port for an hour on electric with battery power - then carry out their open sea work on diesel power. The aim of this innovative hybrid solution is to enhance conventional power and propulsion systems. Vessels can reduce emissions and improve fuel consumption whilst extending engine maintenance periods and engine life.

Green Energy plus a Viable Business Case

This is not just green energy for the sake of it. ‘The Hour Of Power’ focuses on hybrid solutions linked to viable business cases. For commercial and professional organizations the concept of running vessels with zero emissions at up to 10 knots for one hour will shape decisions that lead to improvements of in-service systems and procurement of next generation vessels. The overall objective is fuel saving and improved efficiency by all means.

For the marine industry to move forward it needs to utilize expertise from aviation and other sectors to drive this innovation and support relevant safety standards. Automotive manufacturers in Europe, the Far East and the U.S. have recognized that hybrid technologies such as PHEV (Plug-in Hybrid Electric Vehicle) utilizing lithium ion batteries will be dominant for the next decade. Reducing emissions from busses and trucks in the world’s major cities has been a major driver for lithium ion battery power storage. The need for self sufficient land based grid applications has further extended the capabilities of next generation battery and hybrid technology.

Serial and Parallel Hybrid Power Systems

Diesel / electric systems have been used in large ships and submarines for many years but these are not hybrid systems. The diesel / electric vessel uses its engines to connect directly to an electrical generator. The power in the system is then transferred electrically to the propeller shaft via a motor controller and electric motor. The system may have multiple generators and multiple motors. By strict definition this is not a hybrid as there is no storage of electric energy.

There are currently two main types of hybrid system. Firstly a serial hybrid, where the engine in the system only powers a generator and is not mechanically connected to the propeller shaft. Secondly a parallel hybrid, where the engine is mechanically connected along with an electric ‘machine’ that can operate as both a propulsion motor and a generator. The reduced electric propulsion, generator and battery demands of a parallel system substantially reduce the cost compared to a serial system. Parallel systems are more likely to win initial market acceptance because of a perceived greater reliability, as the ‘trusted’ diesel engine is still connected to the propeller shaft with the electric propulsion adding a redundant system.

Until recently it has not been possible to transfer such systems successfully to smaller craft. A European Union funded project called HYMAR (High efficiency hybrid drive trains for small and medium sized marine craft) set out to develop an optimized hybrid system. HYMAR developed a parallel hybrid system that has been installed, tested and validated on marine craft. The optimized hybrid system developed during the project offers three major advantages - no detectable emissions, no discernible noise and a substantial reduction in fuel consumption.

Hybrid Power & Propulsion Systems Increase Efficiency

We are entering a period of rapid change and commercial opportunity in the hybrid marine market. Boat builders, engine manufacturers, designers and naval architects are now developing systems for survey vessels, superyacht tenders, patrol vessels and unmanned craft. Benefits include improvements in energy reliability, increased fuel efficiency, lifecycle cost reductions and reduced emissions. DNV-GL USA recently stated that, ‘energy storage is an exciting new technology, but the offshore E&P sector of the oil and gas industry has yet to truly take advantage of it. Tugboats, workboats and OSVs are particularly suitable for hybridization.’

When studying work cycles of vessels it is relatively straightforward to make a decision for new builds on whether to go for all electric or a diesel / electric hybrid system. For example a ferry operating over a short route with a long stopover each end could offer the perfect work cycle for ‘electric only’ with a land based charging system. Other issues, such as the cost of downtime and structural alterations affect viability calculations for retrofit of in-service craft.

BAE Systems is a provider of hybrid propulsion systems with technical experience in hybrid technology for land-based applications. David Adamiak, Senior Manager Business Development at BAE Systems HybriDrive said, ‘From over 10 years experience supplying hybrid technology to bus and transport sectors we know that cost-benefit calculations start with the initial purchase of the system. Payback periods can be based on the life cycle of the vessel and life cycle of the hybrid power system. Once a system is defined projections of savings can be based on engine management data linked to work cycles.’ Hybrid systems are infinitely scalable which enables owners to specify what they are trying to achieve over a period of time or an entire fleet. David Adamiak added, ‘We supplied a HybriDrive system to the 19 m (62 ft.) research vessel Spirit Of The Sound. She runs virtually silently on battery electric power for two hour study cruises on Long Island Sound.’

Hybrid Systems and ‘The Hour Of Power’

Certain maritime sectors are potentially well suited to ‘hybrid’ diesel / electric systems. These include wind farm support vessels (WFSV) and pilot boats that have relatively consistent duty cycles, often running seven days a week to drop off or collect technicians and pilots. Focus is now on the sub IMO / sub 24 meter (80 ft.) workboat, pilot boat and patrol craft sectors to investigate the engineering and systems integration required to bring together viable and sustainable solutions. With vessel life cycles of over 20 years, naval architects and builders of new craft will offer designs that have space and access routes to enable retrofit of hybrid installations. Speed limits in harbors and channel approaches at beginning and end of daily transits may mean that ‘The Hour Of Power’ is all that is required for the electric part of the cycle.

Next Generation Cells & Batteries

The next generation of cells and batteries are key technology developments that are making marine hybrid systems potentially viable. Battery chemistry such as Lithium-ion offer impressive power solutions and the business case is starting to fit for commercial operators. Since there is no single system that fits every application it is important to work with manufacturers that have flexibility in cell manufacturing and offer scalable solutions. New factories with fully automated processes are designed to ensure consistently high quality cells and quality control of the entire battery management system.

The marine sector can learn from battery advances in aviation and land transport sectors. Michigan based XALT Energy offer several variants of High Energy, High Power, and Ultra Hi-Power cells. Robert Young, Technical Lead for Marine Applications at XALT Energy, said, ‘our team of engineers have worked to the highest standards developing electric and hybrid energy solutions for the automotive sector. XALT Energy not only has the necessary knowledge, but also the experience of taking high voltage battery projects from concept through production into the finished system.’

Hybrid Marine Power & Propulsion Workshop

In May 2015 the Hybrid Marine Power & Propulsion Workshop brought together a group of experts in Southampton, U.K., to explore the possibilities of utilizing hybrid power and propulsion systems in the professional marine sector. Focussing on sub IMO / sub 24 m (80 ft.) vessels, the group highlighted the potential of the Hour Of Power concept for wind farm support vessels, pilot boats, patrol craft and harbor service vessels.

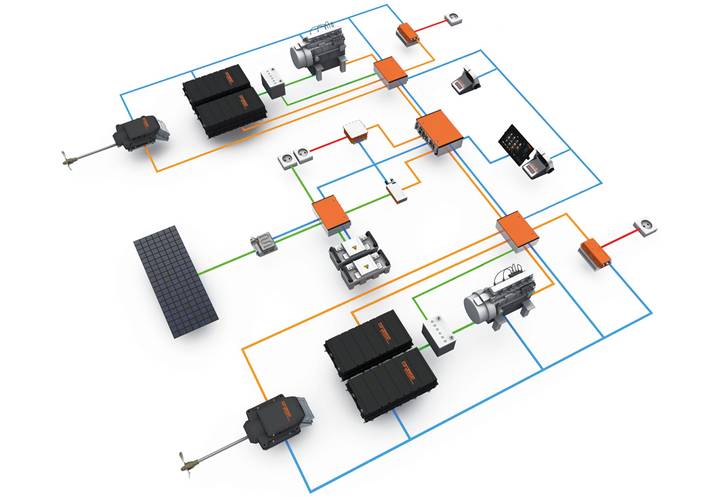

At the hybrid marine workshop Christoph Ballin, co-founder & CEO of German manufacturer Torqeedo, explained the development of high-power integrated propulsion systems for serial production, ‘Torqeedo Deep Blue hybrid power and propulsion for the professional marine sector is based around components of the proven and multiple innovation award-winning system for electric hybrid yachts. The hybrid system can provide drive systems and supply the power required onboard. The use of renewable sources of energy has also been integrated into the energy management system. Professional users of the hybrid system can travel silently and use environmentally friendly sources of energy in port and at lower operating speeds.’

Following the hybrid marine workshop Robert Young added, ‘We are now working with boat builders, naval architects and marine operators to analyse different workboat duty cycles. Engine management data can be matched to battery characteristics to develop the most efficient solutions. XALT Energy onboard energy management systems are designed to ensure that battery systems operate at optimum performance. The objective is hybridizing and electrifying marine vessels to produce financial benefits and reduced emissions.’

Wind Farm Service Vessels and The Hour Of Power

Multi role Wind Farm Service Vessels (WFSV) enable fast personnel transfer with the capability for utility work such as moving equipment and delivery of spares. As the demand for wind farm support has intensified, vessels have been specifically developed for transiting to wind farms in a wide range of conditions then delivering technicians onto wind farm turbines.

If wind, wave and tidal energy installations want genuine ‘green’ credentials it is logical to reduce consumption of fossil fuels wherever possible. The Hour Of Power concept lends itself to WFSV operating in the ongoing wind farm maintenance phase. A conventional diesel powered vessel with a bank of batteries onboard the vessel can be specified to run at hull speed, usually around 10 knots, for an hour at a time on battery electric power.

A typical working day starts with the WFSV captain and crew preparing the vessel, then passengers arrive. The vessel would first be disconnected from shore power which has been used for overnight battery charging. The vessel can leave the dock and harbor on battery electric power, which also means zero emissions. At the outer sea buoys diesel power takes over for the high speed transit out to the wind farm and to deliver the technicians onto the wind turbines, during this time the batteries are re-charging. Many vessels then have hours of waiting in the wind farms, as they are on standby they cannot anchor. Loitering at low speed and low revs is not an efficient load cycle for diesel engines, plus it leads to increased maintenance and reduced engine life. This loitering period could be on battery power. Later in the day diesel power is used for the high speed transit back to port, the batteries are re-charging. At the outer sea buoys battery electric power takes over to enter the harbor, with zero emissions. At the dock shore power is then re-connected for overnight charging.

Indentifying the viability of hybrid diesel / electric power for offshore wind farm support vessels (WFSV) is an interesting project that links green energy onboard with renewable energy from the environment. Hooking up to offshore wind farm turbines may even provide charging options. Many wind farms are ‘overplanted,’ this means there is more energy generated by wind than is required for the grid on land. This surplus allows for downtime and maintenance of turbines. For offshore wind farms in sea areas such as the Dogger Bank in the North Sea which is over 125 km (80 miles) from land, wind generated electricity could be utilised at source from the local offshore grid.

Looking To The Hybrid Future

For naval architects working in the commercial marine sector class rules, safety, performance and cost are relevant when considering innovative battery power and diesel electric propulsion systems. The challenge for designers is to engineer solutions utilizing hybrid technology which are affordable plus manageable in terms of physical size, weight and maintenance.

As new sources of energy become available it is important to identify which energy source best fits the vessel, duty cycle and environment to give efficient power when it is needed. Since no two vessels, routes or captains are alike, decisions can be improved with data logging and analysis. Commercial Off The Shelf (COTS) power management systems will bring together diesel, electric and battery data to create optimised whole vessel hybrid systems.

As ocean going shipping, automotive, transport and aviation move rapidly towards hybrid solutions it will be interesting to see how the marine industry decides to utilize the numerous opportunities.

The Author

John Haynes is an Associate Fellow of the Nautical Institute, a Yachtmaster Ocean and Advanced Powerboat Instructor. Subject matter expertise includes high speed craft consultancy, product development and specialist training. He is Operations Director of Shock Mitigation www.shockmitigation.com and founder of the RIB & High Speed Craft Directory that brings together specialist boats and equipment for the sub IMO / sub 24 m professional sector worldwide www.ribandhsc.com

Hybrid Marine Power & Propulsion Conference

Lifeboat College Poole UK – October 6-8, 2015

This unique event brings together an international group of experts, to identify the potential of utilising hybrid power and propulsion systems for vessels in the sub IMO / sub 24 m sector. Attendees will include professional, commercial and military end-users, boat operators, boat builders, engine manufacturers, mechanical & electrical engineers and naval architects.

Hybrid Conference Website:

http://shockmitigation.com/inner-page/hybrid-marine-conference/40/6/

Hybrid Conference Organiser:

Julie Arthur +44 (0)7449 000228 [email protected]

(As published in the August 2015 edition of Maritime Reporter & Engineering News - http://magazines.marinelink.com/Magazines/MaritimeReporter)