Schottel Touts Noise Signature of Transverse Thruster

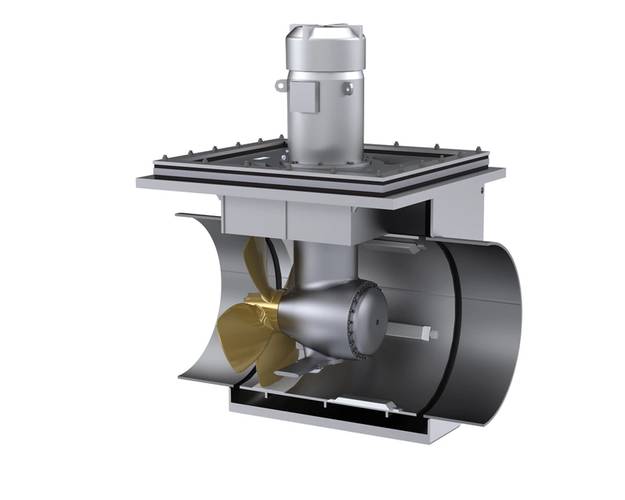

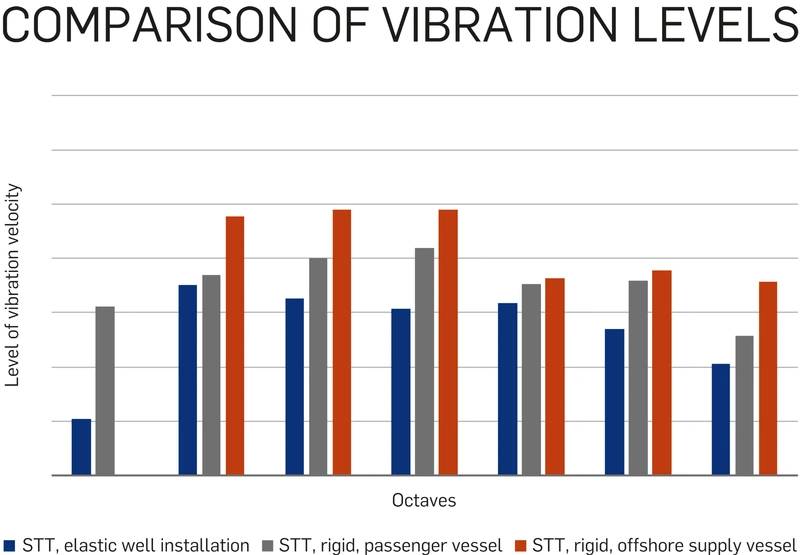

The Schottel TransverseThruster with elastically mounted well installation reduces sound emissions by up to 11 dB, according to the manufacturer, with the added bonus of minimized underwater noise, too. The particularly low-vibration design of the STT is suitable for vessels of all types and sizes.

In addition to reduced sound generation from the propeller and its surrounding structure, the well installation brings another advantage: since the propulsion unit is not welded to the vessel structure, flexible access to the unit is possible. This facilitates maintenance work and eliminates the need for propulsion-related stays in dry dock. This allows to keep idle times as short as possible and guarantees high availability of the vessel.

The elastic well installation is available for SCHOTTEL TransverseThrusters with a power range of 125 to 6,500 kW.

The survey, wreck-search and research vessel Atair of the BSH – German authority for maritime tasks (Bundesamt für Seeschifffahrt und Hydrographie) – is equipped with Schottel propulsion solutions. In addition to a Schottel PumpJet, the propulsion system of the SILENT R-rated Atair includes a Schottel TransverseThruster type STT 170 (200 kW) in the stern and a Schottel TransverseThruster type STT 1 (330 kW) in the bow.

To reduce the noise generation of the STT 1 in the Atair to a minimum, the dynamic behaviour of the transverse thruster was comprehensively analyzed and designed to minimize structure-borne noise. Vibration and pressure pulses are further reduced due to a low propeller load and the sound-optimized design of the five propeller blades.

The Schottel TransverseThruster with elastically mounted well installation guarantees greater comfort and reduces sound emissions by up to 11 dB.Chart courtesy Schottel