Roxtec Provides Safety Services for Petrobras FPSO

Multinational petroleum corporation Petrobras turned to cable and pipe seals specialist Roxtec for verification of the cable and pipe transits on board the P-68 floating production, storage and offloading vessel (FPSO) in a Brazil shipyard before final approval from the classification society.Petrobras also asked the cable and pipe transit specialist to educate engineers and installers of Petrobras and the Jurong Shipyard on how Roxtec seals work.A Roxtec team consisting of sealing experts and inspectors from Sweden…

Roxtec Fire Lab Opens

Roxtec reports that it has more than doubled its fire resistance testing capacity, opening in Sweden a new laboratory that creates conditions for continuous development of safety products.The fire lab is located at the Roxtec headquarters in Karlskrona, Sweden, and it will play a key role in the product development and pre-certification process for the sealing solutions. With the lab Roxtec engineers and technicians can prepare tests with exactness. Every test object must be tested as an entire system in a realistic environment.

Roxtec Secures Order for Britain’s $265m Polar Ship

International manufacturer Roxtec is helping protect Britain’s new £200m ($265m) polar research vessel - RRS Sir David Attenborough – after supplying a range of specialist safety seals.The new build ship is being funded by the Natural Environment Research Council (NERC) built by Cammell Laird in Birkenhead and run by the British Antarctic Survey (BAS).It will operate in extreme conditions in both Antarctica and the Arctic, enduring up to 60 days in sea-ice for scientists to gather…

More Than 20,000 Design Engineers Use Roxtec Transit Design Tool

Cable and pipe transit specialist Roxtec's complimentary, web-based tool has become an everyday help for engineers striving to ensure safety and cost-efficiency. Roxtec Transit Designer is an online application that simplifies the selection of sealing solutions as well as the entire process concerning cable and pipe transits. Designers just enter their input to get full documentation. They can, in fact, generate hole-cuts, drawings and documents in minutes. Why do tens of thousands of design engineers use the Roxtec Transit Designer?

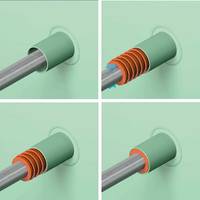

Beele Engineering Expands Sealing Plugs Range

Piping transits are a potential source for fire spread, as fire in one room could easily break through them into adjacent areas. There are various sealing solutions offered to prevent this from happening, such as the SLIPSIL and DYNATITE sealing plugs from Beele Engineering. The Aalten-based company has expanded its supply range to now include XL versions of these products, and in doing so, has simplified further the ability to make pipe transits fire-resistant. Beele Engineering said its sealing plugs are deployed to make pipe transits fire-resistant and smoke and gas-tight.

Keeping a Tight Lid on Tier III & Sealing Solutions

With more than 90 percent of global trade carried by sea, shipping is a major battleground in the reduction of emissions. Tier III is the latest emission standard pertaining to NOx emissions from marine diesel engines. Tier IV is expected to come into effect for 2020 – with engine manufacturers already seeking sealing components to future-proof engines well into the next decade. Here we explore challenges faced by diesel engine operators in the face of Tier III, and how the correct selection of sealing materials could deliver better performing solutions.

Roxtec Services US Launched

Roxtec has launched a new inspection, maintenance and installation training company for the United States: Roxtec Services US aims to increase safety for the marine and offshore markets in the area of cable and pipe transits. High safety standards require correctly installed, properly maintained and easily inspected sealing solutions. As sealing experts, Roxtec said it knows how important cable and pipe transits are when it comes to protecting life and assets. No matter when the vessel or platform was built, it has most likely undergone upgrades which required changes to cable and pipe sealing. These upgrades, combined with years of maintenance in a tough, corrosive environment can quickly compound and negate any protection against fire, gas and water.

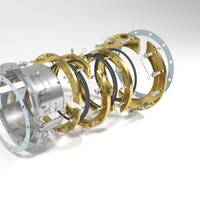

Wärtsilä REvolution system takes sealing technology to New Level

The new Wärtsilä REvolution system is a digital management system that controls, monitors, records and analyses the performance of seals autonomously in real time, increasing the predictability and reliability of sealing solutions in rotating equipment. Wärtsilä's new digital management system revolutionises sealing technology in the hydropower industry. The system incorporates machine learning, predictive modelling and model predictive control (MPC) techniques to provide customers with intelligent, real-time active management of the sealing interface fluid film, minimising wear and removing the sealing components from the maintenance schedule critical path.

Roxtec Launches Inspection and Maintenance Team

Yet another company has set sails under the Roxtec flag. Roxtec Services AB offers inspections, maintenance work and installation trainings within the crucial area of cable and pipe transits. “We inspect and maintain sealing solutions on marine vessels and offshore units to make sure they keep up performance and meet the safety requirements from the classification societies,” said Roger Johansson, Executive Vice President Business Area Marine & Offshore at Roxtec. High safety standards require correctly installed, properly maintained and easily inspected sealing solutions.

Fugitive Emissions: The New Regulatory Elephant in the Room

W&O Supply and Chesterton team up to reduce harmful emissions out in front to the EPA’s monitoring program. It’s less expensive than you might think. From the UK’s Maritime and Coastguard Agency comes the September 2014 news of a barge operator fined for releasing dangerous gas into the atmosphere. The UK-based firm was made to pay almost £111,000 in fines and costs as a result of emitting unsafe levels of a gas; in this case, hydrogen sulphide (H2S). And, while an investigation by the MCA showed a number of health and safety failings by the operator, the bottom line was that not enough was done to stop the offending vapors from escaping into the atmosphere.

Lagersmit, Back to Its Old Name

Starting in December 2014, IHC Sealing Solutions will operate under the new – but also old and trusted – name of Lagersmit. The new pay-off line ‘The Origin of Sealing Solutions’ pays tribute to the company’s rich history and its desire to supply the best sealing solutions, now and in the future. On 28 November 2014, the new name was unveiled at a party for the employees of the ‘new Lagersmit’. Why this new name and pay-off line? In the summer of 2014, the company became independent and consequently separated from Royal IHC. With this new independence, Lagersmit aims to focus more on its core business, which is to supply sealing solutions for ships, pumps and tidal turbines.

LNG on the Rise

As the world’s economies search for sustainable, reliable, renewable energy sources, they are also more closely examining a range of fossil fuels to find the cleanest, least harmful of those to cut carbon emissions and improve air quality in the process. In the drive to cut carbon emissions, interest in liquefied natural gas (LNG) is growing. LNG is being looked at not only as fuel for generating electricity and heat, but also as a fuel for powering marine vessels, road vehicles and trains. With the recent development of abundant shale gas deposits in the United States, the LNG market is really set to take off. The common method for transporting natural gas worldwide is to liquefy it so it takes up less volume and can be transported in specialized LNG carrier vessels.

Going Big for Sustainability

Orkot Marine Bearings, developed and manufactured by Trelleborg Sealing Solutions, contribute to the build of one of the world’s most efficient and largest containerships, the Maersk Triple E class family, built by Korea’s Daewoo Shipbuilding. Orkot TXMM and TLMM bearings were developed to meet the requirements of ever changing markets. The synthetic composite bearing materials incorporate solid lubricants to provide exceptional wear resistance, virtually no swell in water and great dimensional stability, the manufacturer said.

Going Big for Sustainability

Orkot Marine Bearings, developed and manufactured by Trelleborg Sealing Solutions, contribute to the build of the world’s largest and most efficient containerships, the Maersk Triple E class family, built by Korea’s Daewoo Shipbuilding. Orkot TXMM and TLMM bearings, with their track record of performance over 60 years, were developed to meet the requirements of ever changing markets. The synthetic composite bearing materials incorporate solid lubricants to provide exceptional wear resistance, virtually no swell in water and great dimensional stability.

IHC Seals Earn DNV GL Verification

IHC Sealing Solutions has received an important third-party verification from DNV GL, a ship and offshore classification society. This means that the company’s Supreme Ventus and Supreme Athmos seals (that guarantee zero oil emissions) are now compatible with mineral oils that are used in U.S. waters in compliance with the Vessel General Permit (VGP). On December 19, 2013, the revised VGP, issued by the U.S. Environmental Protection Agency (EPA), came into force. This new permit mandates the use of environmentally acceptable lubricants for all oil-to-water interfaces, such as stern tube and thruster seals, on all merchant vessels that are 79 feet or longer and sailing in U.S. coastal and inland waters.

Royal IHC sells Subsidiary IHC Sealing Solutions

Royal IHC (IHC) has reached an agreement to sell 100% of its shares in its subsidiary IHC Sealing Solutions to new owners Willem Steenge, who as CEO is partly responsible for the strong growth of IHC Sealing Solutions in recent years, and Rabo Participaties (RaPar). The sale enables IHC to strengthen its focus on its core business: offering integrated innovative vessels, advanced equipment and life-cycle support to the dredging, wet mining and offshore construction industries.

Wärtsilä Environmental Seal Systems First to Gain Recognition

Wärtsilä has received an important service level recognition for its Wärtsilä Airguard and Wärtsilä Oceanguard propeller shaft sealing systems from Lloyd's Register. The recognition of Lloyd's Register, a marine classification society, confirms that the sealing systems meet the US Environmental Protection Agency's (EPA) requirements. Wärtsilä, the marine industry's leading solutions and services provider and a pioneer in environmentally sustainable sealing solutions, is the first company in the industry to gain this recognition from Lloyd's Register. In March 2014, Wärtsilä announced that its Wärtsilä Airguard and Wärtsilä Oceanguard…

Hydrex, Wärtsilä Partner for Subsea Repair

Last month a Hydrex diver/technician team carried out underwater stern tube seal repairs on a 110-meter offshore supply vessel in Bunbury, Australia. The rope guard covering the stern tube seal assembly was missing and the seal box had come loose after a mooring rope got tangled around the assembly. An emergency on-site repair was necessary. Hydrex therefore mobilized a diver/technician team to the vessel’s location and was able to carry out the entire operation on-site and underwater. This operation saved the owner an expensive and time-consuming trip to drydock.

RSC Bio Solutions Certifies More HF Products for VGP 2013

Products Join 100, 3000 Series Hydraulic Fluids and Safecare Cleaners as VGP Environmentally Acceptable Products that Deliver Technical Feasibility to Marine Industry. RSC Bio Solutions has announced that its EnviroLogic 200 and 200 EP series of Environmentally Acceptable Lubricants (EALs) and its EnviroLogic 802 grease, as well as the products’ constituent components, have been evaluated by independent laboratories to meet the U.S. Environmental Protection Agency’s (EPA) definitions of biodegradable, minimally toxic and not bioaccumulative.

IHC Sealing Debuts “Zero-Pollution” Seal

IHC Sealing Solutions, part of IHC Merwede, will launch the zero-pollution SUPREME Athmos seal at the Europort exhibition in Rotterdam, November 5-8. According to the manufacturer, the SUPREME Athmos seal enables ships – with limited draught up to approximately five meters – to prevent oil from being emitted into the environment. A system has been developed to provide a safe and sustainable operation by capturing every possible drop of oil. Water is prevented from entering the system by collecting any leakages from the seal into a drain tank.

Aker Solutions Acquire UK Subsea Company

Aker Solutions has agreed to acquire a majority stake in Aberdeen-based Enovate Systems Ltd. Enovate Systems Limited is a leading technology company within the subsea well control equipment sector. The financial details of the acquisition are undisclosed. Enovate, which currently employs 62 people, has developed a wide range of unique and patented components and products for use in open water workover systems, in riser workover systems, rigless intervention systems and drilling safety systems. Specific advantages are superior cutting and sealing capabilities and the unique use of complete metal-to-metal sealing solutions which significantly reduce the probability of leakage and improve safety.

Freudenberg acquires Vector Technology Group

Freudenberg Oil & Gas expands its position and expertise in the upstream segment of the oil and gas market with innovator in offshore sealing solutions. Freudenberg Oil & Gas announced that on January 11, 2013, 100% of the shares of Vector Technology Group, a major global supplier of high integrity sealing solutions for the oil and gas industry, were acquired by parent company Freudenberg Group, headquartered in Weinheim, Germany. The shares were acquired from the private equity firm HitecVision headquartered in Stavanger, Norway.

Trelleborg is Raising the Bar

Trelleborg held its Capital Markets Day on Thursday, 6 December in Berns Salonger, Stockholm, Sweden. At the event, Trelleborg took the opportunity to release new financial targets for the Group and to launch a more focused organizational structure. New financial targets are in line with Trelleborg’s ambitions to increase value creation and to be a world leader in selected market segments and geographic markets. They include organic growth of 5 percent or above as well as an operating margin before interest and tax of 12 percent or above of sales. Return on shareholders’ equity is set to be 15 percent or above. “Trelleborg's new financial targets shall be seen as realistic, reachable and in line with responsible risk taking.