Sea Drone Warfare has Arrived, and the US is Floundering

The U.S. Navy's efforts to build a fleet of unmanned vessels are faltering because the Pentagon remains wedded to big shipbuilding projects, according to some officials and company executives, exposing a weakness as sea drones reshape naval warfare.The lethal effectiveness of sea drones has been demonstrated in the Black Sea where Ukraine has deployed remote-controlled speed boats packed with explosives to sink Russian frigates and minesweepers since late 2022.Yemeni-backed Houthi rebels have employed similar vessels against commercial shipping in the Red Sea in recent months…

Maritime Partners, USCG Ink Design Basis Agreement for Innovative Hydrogen One Towboat

The developer of an innovative towboat engineered to run on hydrogen generator technology has signed a Design Basis Agreement (DBA) with the U.S. Coast Guard, helping to clear the regulatory path toward the vessel's eventual entry into service.The first-of-its-kind vessel, Hydrogen One, is being produced by Maritime Partners, the Metairie, La.-based maritime financing company that unveiled plans for the groundbreaking towboat in 2021.Designed by Seattle-based Elliott Bay Design Group…

Fortescue’s Ammonia-Powered Vessel Wraps Up Sea Trials in Singapore

Fortescue, with the support from the Maritime and Port Authority of Singapore (MPA) and partners, has completed propulsion and maneuverability trials of its Singapore-registered Fortescue Green Pioneer dual fuel ammonia-powered vessel in the Port of Singapore.The trials were conducted using 6.4 m3 (4.4 tonnes) of liquid ammonia, in combination with diesel and Hydrogenated Vegetable Oil (HVO), a second-generation biofuel, as marine fuel over 10 days from April 23, 2024 to May 2…

China's Next-generation Aircraft Carrier Starts Sea Trials

China on Wednesday launched sea trials for the Fujian, its third and most advanced aircraft carrier, state media reported.The start of tests by the Chinese navy came nearly two years after the aircraft carrier was first unveiled in June 2022.The Fujian, entirely designed and built domestically, is larger and more advanced than the Shandong, commissioned in late 2019, and the Liaoning, which China bought second-hand from Ukraine in 1998.The development of the Fujian is part of a build-up central to President Xi Jinping's bid to make China the preeminent military power in the region…

All American Marine Delivers Hydrofoil-Assisted Tour Vessel to Phillips Glaciers

Bellingham, Wash. shipbuilder All American Marine (AAM) has delivered a new high-speed and long-range eco-tour vessel to Phillips Cruises and Tours. The vessel will operate daily in Prince William Sound and will be based out of Whittier, AlaskaDeveloped by Nic de Waal of Teknicraft Design in Auckland, New Zealand, the Chugach Express boasts an 84.5’ x 30.7’ semi-displacement aluminum catamaran hull.The new sightseeing vessel integrates the signature Teknicraft Design symmetrical and asymmetrical combined hull shape, bow wave piercer, and a patented hydrofoil-assisted hull design.

King to Open MARIN's Seven Oceans Simulator Center

His Majesty King Willem-Alexander of The Netherlands will open the Seven Oceans Simulator center (SOSc) of MARIN, the Maritime Research Institute of the Netherlands, on Tuesday, May 28, 2024.The opening program takes place in the Shallow Water Basin, one of MARIN's test facilities for ship models. Experts from the maritime research institute, the NL Coast Guard, Search & Rescue Institution KNRM and maritime service providers talk about shipping safety, about working in increasingly busy seas and about involving the crew in the design of new ships.

Rear Adm. Philip Sobeck: MSC Needs More Mariners, New Ships

Founded as the Military Sea Transportation Service (MSTS) and renamed Military Sealift Command in 1970, MSC today not only support the Navy, but we are the Department of Defense's provider of all sealift. Maritime Reporter & Engineering News recently interviewed Rear Adm. Philip Sobeck, U.S. Navy, for insights on the service today and it’s needs to grow in the future.What makes MSC so vital to the Navy’s fleet and our military forces around the world?When we look at the history of contested logistics in World War II…

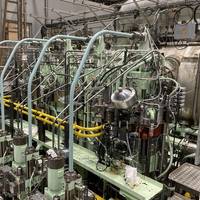

WinGD’s Short-Stroke Engine Passes Shop Test

WinGD will record the first installation of its new X-S short-stroke engine design following successful factory acceptance tests with engine builder Dalian Marine Diesel in March.The six-cylinder, 62cm-bore 6X62-S2.0 engine will be installed on a pulp carrier being built for a Chinese owner at COSCO Dalian shipyard.The X-S series succeeds the well-established RT-flex50 and RT-flex58 engines and is available in 52cm and 62cm bore sizes, for the range of fuel options including traditional diesel or dual-fuel LNG…

Advanced Digitalization Discussed at Singapore Maritime Week

The Maritime International Advisory Panel (IAP) held its third annual meeting on April 16, 2024, during the Singapore Maritime Week 2024. This year, the Maritime IAP held in-depth discussions on the key developments in the maritime sector, including decarbonization, green financing, digitalization and cybersecurity.Established in 2022 by the Ministry of Transport (MOT) and the Maritime and Port Authority of Singapore (MPA), the Maritime IAP aims to seek international perspectives on key long-term trends and developments that will shape the maritime industry.

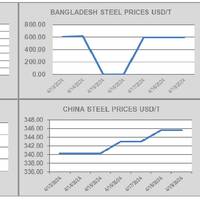

Ship Recycling Markets Face Varied Fundamentals

This week, various holidays concluded across the globe just as Indian sub-continent ship recycling markets started to perk up amidst fundamentals that have independently enjoyed varying degrees of volatility and resurgence over recent weeks, reports cash buyer GMS.“Steel plate prices in Bangladesh and Pakistan remained flatlined at respectively firm levels - the effects of which has only helped these markets grab their share of high-priced fixtures since the start the of the year - all while the ever-volatile Indian plate price that fell last week…

New Order for MAN’s Ammonia Engine

Imabari Shipbuilding will install a MAN B&W 7S60ME-Ammonia engine with SCR in connection with the construction of a 200,000 dwt bulk carrier for a joint venture between K Line, NS United and Itochu Corporation.The business represents one of the first projects for MAN Energy Solutions’ ammonia-powered engine that is currently under development in Denmark. MITSUI E&S will build the engine in Japan.Bjarne Foldager – Country Manager, Denmark – MAN Energy Solutions, said: “The interest in this revolutionary engine had been overwhelming…

US Coast Guard Gives All Clear After Louisiana Spill Response

The Unified Command completed a line integrity test on the Main Pass Oil Gathering (MPOG) company's pipeline system near Plaquemines Parish, southeast of New Orleans, the U.S. Coast Guard said on Monday."Following a successful line integrity test of the MPOG line, the Unified Command has stood down its work to respond to the oil release observed on November 16," they added.A line integrity test confirms that all points are leak-free.In Nov 2023 an oil spill was reported near the…

Newport News Completes Dry Dock Work for Aircraft Carrier USS John C. Stennis

HII’s Newport News Shipbuilding division has completed the dry dock portion of the refueling and complex overhaul (RCOH) of Nimitz-class aircraft carrier USS John C. Stennis (CVN 74).Following the recent flooding of more than 100 million gallons of water into the dry dock, USS John C. Stennis was moved to an outfitting berth at the shipyard, where the remainder of the RCOH work and testing will be completed.During the dry dock phase of the RCOH, USS John C. Stennis received significant upgrades and began an extensive overhaul process, both inside and outside the ship.

Survitec Achieves ISO 23678 Certification

Survival technology solutions provider Survitec reports it has become one of the first maritime safety companies to achieve ISO 23678:2022 1-4 certification.The standard was introduced in 2022 to establish the uniform and consistent training of personnel involved in lifeboat inspection, taking into account the mandatory requirements of resolution MSC.402(96).Achieving ISO 23678 certification was also a key factor in Survitec receiving renewed approval for the maintenance, inspection…

Faulty Missile Launcher Closes Busy Danish Sea Lane

An activated but faulty missile launcher on a Danish navy vessel triggered a closure of airspace and shipping traffic in the Great Belt strait on Thursday, the Danish armed forces said.Denmark's National Maritime Authority had earlier warned ships not to sail through the Great Belt strait, one of the world's busiest sea lanes and the main maritime access to the Baltic Sea, due to the risk of "falling missile fragments"."The problem occurred during a mandatory test where the missile launcher is activated and cannot be deactivated…

Svitzer Targets Methanol-Fuelled MAN 175DF-M Engine

MAN Energy Solutions and Svitzer have signed a Memorandum of Understanding (MoU) focused on the development of a methanol-fuelled version of the MAN 175D engine. Designated 175DF-M (Dual Fuel-Methanol), the MoU targets the finalisation of a field-test agreement based on which a dual-fuel engine and plant equipment will be installed on board one of Svitzer’s newbuild tugs.Svitzer has a long-standing relationship with MAN Energy Solutions, especially recently with the MAN 175D engine.

Chevron Charters Its First Hybrid Electric Bunker Tanker

Chevron has chartered its first hybrid electric bunker tanker from V-Bunkers that will be used to provide fuel to maritime customers in Singapore region.The bunker tanker is expected to consume approximately 20% less fuel compared to a conventional tanker as it goes about its operations, which can reduce emissions and costs, according to Chevron.Instead of three auxiliary engines, as a conventional fueling barge this size would have, the barge has two auxiliary engines and an electric power distribution system.Current technology doesn’t allow barges to run completely on electricity…

Innovative ‘Wall Climbing Robot’ for Ship Inspection Earns ClassNK Endorsement

The wall climbing robot for steel structures - developed by Mitsui O.S.K. Lines, Sumitomo Heavy Industries, and MOL Ship Management to support ship inspection and maintenance - has completed a demonstration test and earned the Nippon Kaiji Kyokai (ClassNK) Innovation Endorsement.The Innovation Endorsement is ClassNK's third-party certification program. It certifies and supports initiatives that contribute to the sustainable evolution of maritime and offshore businesses.The robot…

Esgian Week 13 Report: Demand Shifts

Esgian reports shifts in demand in its Week 13 Rig Analytics Market Roundup.Report overview:ContractsADES has received a Letter of Intent (LOI) from PTTEP Energy Development Company Limited for an 18-month jackup drilling contract in the Gulf of Thailand. Operations are expected to begin in the second half of 2024, with an unspecified jackup.Drilling Activity and DiscoveriesThe Norwegian Offshore Directorate (NOD) has granted Aker BP a drilling permit for an exploration well in…

Esgian Week 14 Report: Major Jackup Contract Suspensions

Esgian reports various drilling contractors disclosing details of discussions with Saudi Aramco regarding jackup contract suspensions in its Week 14 Rig Analytics Market Roundup. These contractors include Shelf Drilling, ADES, Borr Drilling, Arabian Drilling, COSL, and ARO Drilling.Meanwhile, Transocean, Noble, and COSL rigs have firmed up new work in the US Gulf of Mexico, Suriname, and the North Sea, respectively.Report overview:ContractsShelf Drilling has received a notice of suspension of operations on four jackup rigs from a customer in the Middle East.

All FMC Statutes & Regulations in Full Effect Following Baltimore Bridge Collapse

The U.S. Federal Maritime Commission (FMC) on Friday issued a notice reminding regulated entities that all statutes administered by the agency remain in effect while disruption to regular service at the Port of Baltimore is causing many shippers to adjust supply chain operations.Common carriers and marine terminal operators (MTOs) must continue to comply with all statutory and regulatory requirements governing their operations, the FMC said.Demurrage and detention fees must be reasonable.

Study Demonstrates Need for New Fire Safety Rules for Methanol-Fueled Ships

A new fire safety study by survival technology solutions provider Survitec finds that existing fire-fighting methods used to extinguish machinery space spray and pool fires on conventionally fueled vessels are inadequate when dealing with methanol-based fires.This follows extensive comparative fire tests on dual-fuel marine engines using diesel oil and methanol.“Our tests confirm that traditional water mist fire suppression mechanisms do not perform as expected on methanol pool fires and methanol spray fires.

Green Ships ePSV to Feature Amogy’s Ammonia-to-power System

Green Ships Invest has signed a contract to purchase of Amogy’s carbon-free ammonia-to-electrical power systems for a fleet of new environmentally friendly platform supply vessels (PSV). Green Ships, which is designing/procuring so-called ePSVs (electrical PSVs), had signed a memorandum of understanding (MOU) with Amogy in October 2023.Under the newly signed contract, Green Ships Invest will design the ePSV to be equipped with 2 megawatts (MW) of clean energy capacity through the integration of ten of Amogy’s pioneering 200 kilowatt (kW) ammonia-to-electrical power systems.