Ukraine Grain Backlog Prompts UN Call for Faster Ship Checks

With nearly 100 grain-laden ships reaching towards the horizon off Istanbul, the U.N. official overseeing exports from Ukraine is asking Russia and other parties to end "full-blown" inspections of outgoing vessels to ease the backlog.Ukraine has exported more than 6.8 million tonnes of grain and other foodstuffs, about a third of its storage, since a sea corridor from the war-torn country opened in July.The U.N. says the safe passage deal signed by Moscow and Kyiv eased a global food crisis.

Geoquip Acquires Deep-push CPT Vessel

Global offshore geotechnical data acquisition, analysis and reporting specialist Geoquip Marine has confirmed the continued expansion of its fleet with the addition of a further Integrated Geotechnical Survey Vessel (IGSV) the Geoquip Elena.Geoquip Elena is setup as a specialist deep-push Cone Penetration Testing (CPT) vessel and has been acquired to add vital capacity to the demand from offshore windfarm developers, especially in Europe and North America.The Geoquip Elena is a 4000 ton IGSV, 91m in length and 19m in breadth.

Total Joins Maersk-led Shipping Decarbonization Project

French oil major Total said it will contribute to a project led by shipping giant Maersk aiming to develop new alternative fuels and carbon neutral solutions for ships.The nonprofit Mærsk Mc-Kinney Møller Center for Zero Carbon Shipping was formed in 2020 as the maritime industry continues efforts to reduce its environmental footprint. The center will create overviews of decarbonization pathways, accelerate the development of selected decarbonizing fuels and powering technologies, and support the establishment of regulatory, financial and commercial means to enable transformation.

Techcross ECS-A BWMS Earns USCG Type Approval

South Korea-based ballast water management system manufacturer Techcross said its discontinued ECS-A system has been approved in addition to Techcross ECS in the updated approval status of U.S. Coast Guard (USCG) Marine Safety Center (MSC). This means that Techcross, which sells electrolysis-based ECS and ECS-HYCHLOR, has also obtained a new USCG type approval for ECS-A, which is the initial model of ECS.ECS-A received International Maritime Organization (IMO) basic approval the first in the world in 2006.

USCG Implements Handheld Technology for Onboard Oil Testing

With a motto of Always Ready, the United States Coast Guard (USCG) has 11 missions specified by law including drug and migrant interdiction; ports, waterways and coastal security; fishery patrols; search and rescue; and national defense. The USCG’s newest ships including 22 Fast Response Cutters (FRCs) recently entered service with 36 more on order and six new National Security Cutters (NSCs) with two more in the process of being built. Oil analysis plays a critical role in the…

New Oil Spill Tech Solutions Put to the Test

No two oil spill response operations are the same. Each can present new and even tougher challenges for spill responders as they detect, contain and recover spilled oil. Diverse aspects affecting oil spill response operations can be the physical environment, spill monitoring, use of chemical dispersants, and the availability of proper technology for the situation.Some challenges have been met through research and technology development of techniques for dealing with spills. However…

Tech File: An Inside Look at Ballast Tank Linings

The proper lining of ballast tanks is essential and critical to ship safety. Not too many decades ago, ships traveling the North Atlantic routes were experiencing terrible losses from outright sinking in the turbulent seas. It was eventually discovered that the primary culprit was hull failure from ballast tanks rupturing from the inside out due to simple, plain old-fashioned rusting and galvanic corrosion. The U.S. Navy led the way and came up with a recommended formula, or recipe, for a ballast tank coating that paint manufactures could copy in bidding for Navy business.

Aker Arctic’s Ice Lab is Back in Acton

The Finnish icebreaking season typically ends in May. Around the same time, the cooling system in Aker Arctic’s ice laboratory in Helsinki, Finland, is turned off and the model basin is allowed to warm up for the annual summer maintenance break. Aker Arctic operates its own ice model testing facility at the company’s main office in Helsinki, Finland. Using the in-house developed FGX model ice, the 75-meter ice tank can be used to get reliable icebreaking performance predictions for ice-going ships and study other ice-related phenomena in model scale.

Parker Kittiwake Launches 'The Gold Guide'

Parker Kittiwake has announced the launch of the Gold Guide – a definitive reference guide to fuel, hydraulic, and lubricating oil for the marine industry. This first-of-a-kind, comprehensive resource provides vessel owners and operators with all the information needed to understand all aspects of fuel, lube, and hydraulic oil from first principles to testing, monitoring, characteristics and specifications. Furthermore it gives a comprehensive insight into interpreting test results and understanding the potential impact these can have on operational performance and efficiency.

Cortland Australia Earns NATA Accreditation

Customized cable and rope specialist Cortland Company said it has received full endorsement from the National Association of Testing Authorities (NATA) for its inspection and testing facility in Western Australia. The facility has received ISO/IEC 17020 and ISO/IEC 17025 accreditation for the testing and inspection of high performance round slings and ropes used in a range of industries along with associated fittings and hardware. NATA accreditation formally recognizes the facility’s competency in performing specific types of testing and…

Ohmsett: Advancing Spill Response Every Day

The National Oil Spill Response Research and Renewable Energy Test Facility has been an integral part of the spill response community for more than three and a half decades. Tucked away on the shores of the Sandy Hook Bay in central New Jersey resides Ohmsett – The National Oil Spill Response Research and Renewable Energy Test Facility. It has been an integral part of the spill response community for more than three and a half decades. Government agencies, private industry, and oil spill response organizations from around the world have visited the facility for testing, research and training.

Parker Kittiwake Launches Condition Monitoring Starter Kit

Parker Kittiwake today launched the Condition Monitoring Starter Kit. The kit combines the Parker Kittiwake DigiCell combined kit, the Holroyd MHC-Bearing Checker, and a PC tablet with a condition monitoring routine and log book pre-loaded on it to help guide the user in using the products for maximum effect. Created with the aim of introducing the power of condition monitoring to those owners and operators less familiar with it, the Condition Monitoring Starter Kit combines essential tools that protect vulnerable equipment and prevent failure. It utilises modern condition monitoring technology to simplify everyday maintenance observations and provide advance warning of possible maintenance requirements.

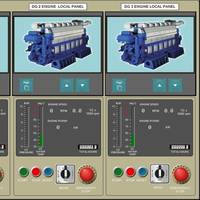

Royston Debuts Engine Diagnostics Service

Diesel power specialist Royston has expanded upon its traditional engine service and repair business with the introduction of a new engine diagnostics, health check and consultancy service. This follows significant investment in personnel recruitment and training, new technology and equipment, and an enhanced software capability for the in-depth analysis of engine and condition monitoring data, Royston said. As well as supporting onboard engine maintenance routines and class surveys…

Transas Launches High Voltage Training Breaker

Coming in response to recently introduced STCW requirements, Transas has launched a high voltage training solution for marine engineering and electrical training. The new rules require training to be conducted using real equipment, leading Transas to partner with the power technology specialist ABB for the development of a real hardware high voltage generator breaker cabinet compatible with the Transas ERS 5000 TechSim simulators with high and medium voltage systems. The Transas High Voltage Training Breaker is designed to train high voltage switchboard operations…

Bal Seal Adds Low-friction Seals Test Service

Test service enhances Bal Seal offering for low-friction seals, verifies friction and leak rate for seals up to 22 in. A new test service introduced by Bal Seal Engineering, Inc. offers verified performance results for Bal Seal low-friction spring-energized seals used in rotary/face applications. According to the company, the service will help OEMs and tier suppliers eliminate unnecessary costs, delays and complications associated with in-house or outsourced seal testing. Rotary/face…

STELLA B1 Well Flow Test Completed

Ithaca Energy Inc. announced completion of flow test operations on the third development well on the Stella field, with the well achieving a flow rate of 12,492 barrels of oil equivalent per day. Well 30/6a-B1Z (“B1”) is the third development well drilled on the Stella field. The well was drilled to a total measured depth subsea of 16,185 feet, with a 2,147 foot gross horizontal reservoir section completed in the Palaeocene Andrew sandstone reservoir. The well intersected high quality sands across a net reservoir interval of 2,034 feet, equating to 95% net pay. This compares to 1,312 feet and 2,514 feet in Stella wells A1 and A2, respectively.

MARAD Study: Renewable Diesel Reduces Emissions, No Harm to Performance

MARAD study shows renewable diesel fuel reduces emissions without impacting engine performance. The Maritime Administration (MARAD) has recently completed tests of renewable biofuel technology onboard the training ship State of Michigan. The project was part of a MARAD initiative to conduct “at sea” tests of advanced renewable fuels and assess its impact on the ship’s engine. The tests compared operational, vibration and air emission differences between regular ultralow sulfur diesel (ULSD) fuel and a 76/33 blend of ULSD and Amyris Renewable Diesel (ARD) fuel, which is derived from sugar.

Thales Secures Contract from UK Navy

Thales has signed a five-year contract with the U.K.’s Ministry of Defence to provide support for the Sonar 2050 antisubmarine sensor used on the Royal Navy’s Type 23 frigate fleet. Sonar 2050 is a medium-range bow sonar currently fitted to 13 Type 23 frigates and is the Royal Navy’s primary hull-mounted antisubmarine warfare sensor. It also provides the ship with passive detection capabilities at lower frequencies. Under the contract, Thales will provide physical support of Sonar 2050 for operational defect rectifications, a worldwide 24/7 helpdesk support service, drydock and afloat support, and test equipment and handling. Thales was awarded the contract in a competitive process by offering a value for money…

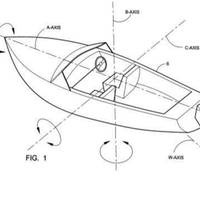

U.S. Coast Guard Publishes Propeller Guard Test Procedure Report

The U.S. Coast Guard's Office of Auxiliary and Boating Safety Wednesday announced the release of the Propeller Guard Test Procedure report, intended for use by developers of propeller guard devices and independent third party testing entities to test propeller guard products in a consistent and repeatable manner. "The report provides the means to evaluate the boat performance characteristics and the level of protection of personnel in the water resulting from the installation of a propeller guard on a particular sterndrive or outboard-powered recreational boat," said Phil Cappel, chief, Recreational Boating Product Assurance Branch.

New Alfa Laval Test & Training Center

Work continues on the Alfa Laval Test & Training Center in Aalborg, Denmark, a facility that will greatly expand Alfa Laval’s marine testing capabilities. The center, which will serve as a springboard for faster and more effective R&D, will further strengthen Alfa Laval’s capacity for innovative marine solutions that optimize the performance of onboard equipment, save energy and help ship owners comply with environmental legislation. While the center’s official inauguration is not scheduled until 15 January 2014, some full-scale prototype testing will be initiated during the month of October.

Rethinking Shroud Technology

MPT’s prop shroud solves WBV and RS Issues and increases performance. The Idea: Terry Smith and William Schultz, an aeronautical engineer with lineage to the original Kort nozzle invention, were both dedicated to offering solutions to known critical vessel issues. Specifically, they pinpointed shock mitigation, reduction of maintenance and replacement costs, prevention of needless tragic injuries and deaths, conservation of fuel for the shipping industry, protection of the environment and its living entities…

NSRP Highlights 19 New Shipbuilding & Repair R&D Projects

The National Shipbuilding Research Program (NSRP) Executive Control Board (ECB) recently selected 19 new R&D projects to be executed, totalling approximately $2.5-million, as part of their core project mission to reduce the costs associated with Navy shipbuilding and repair. NSRP is a collaboration of U.S. shipyards working together to reduce the cost of building, operating and repairing Navy ships by improving productivity and quality through advanced technology and processes. NSRP leverages public/private cooperation to manage cost-shared R&D based on a consensus Strategic Investment Plan.

Drillship Profile: Tungsten Explorer

The Tungsten Explorer is an ultra deepwater, dynamically positioned mobile offshore drilling unit (Drillship). The primary areas of activities of the Drillship shall be in the Gulf of Mexico, West Africa and Brazil. The drillship has drilling equipment on the topside with a continuous main deck and forecastle deck. Three engine rooms which house six diesel engines (7,000 kW x 720 rpm) are arranged aft in the hull. Thruster machinery spaces are arranged in engine rooms and in the forward machinery space of the hull…