Thrustmaster has been building brown water propulsion equipment for more than 30 years. Now the company’s American-made Z-Drive thrusters for inland waterway towboats are the first thruster in the industry to include a built-in mechanical fuse or quick release coupling.

The incorporation of a quick release coupling at the input shaft of the Z-drive gives operators the added protection from the inevitable debris that can line the riverbed. The quick release coupling acts as a mechanical fuse whenever the drive line is blocked, for example should the propeller ingest a log, a tire or other river waste that is typical during daily operations.

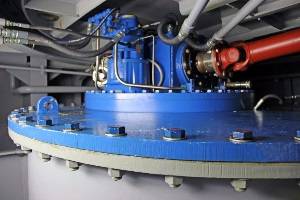

After the obstruction is removed from the propeller, the mechanical fuse can quickly be reset manually. The mechanical fuse, also called a torque limiting coupling, is a component installed on the horizontal input shaft of the Z-drive and connects to the cardan shaft driven off of the engine or electric motor.

Thrustmaster explained the concept behind the quick release coupling: when the propeller or gear set and/or drive line sees any spike in torque above the set limit for the coupling, the coupling instantaneously breaks free allowing the cardan shaft and engine to spin freely without driving the thruster. The propeller and gear set are instantaneously disconnected from the engine saving the propeller, gear sets and bearings, from damage or complete failure. Therefore, not only avoiding the damage, but also operational downtime, unnecessary dry-docking, and crippling cost of repairs typically associated with the competitions’ thruster run-ins with the inevitable debris, the manufacturer noted.

The quick release coupling is a standard component on Thrustmaster’s line of Z drives.

According to the manufacturer, benefits include maximum driveline protection: damaging inertias disengage at once; set torque remains constant over time and quick resetting for maximum uptime.

Thrustmaster Z-drives are designed based on conservative American standards observing ample safety margins. Thrustmaster has built a reputation on designing and manufacturing each Z-drive with a stalwart stainless steel propeller turning in a Kort nozzle with all stainless steel internals. Bolstering the thruster design by fully welding the nozzle to the lower housing for added strength, reducing vibration, and insuring the nozzle is not lost in grounding. Much praise has been given to the generous sizing of the gears, transmission shafts and precision bearings.