StormGeo takes Ownership of Climatempo

StormGeo, part of Alfa Laval, completed the acquisition of Brazil based meteorological service, Climatempo.StormGeo first took an initial 51% stake in the Climatempo Group in 2019. In 2023, a further 38.66% was secured, marking an 89.66% ownership. This takeover sees StormGeo increasing its footprint in the South American market and providing advanced services to the Brazilian customer base.

MAN and Alfa Laval Collaborate on Four-Stroke Methanol Solution

MAN Energy Solutions has announced an agreement with Alfa Laval to develop a methanol fuel-supply solution for MAN four-stroke engines and its fuel-injection technology. As a result, the first four-stroke engine types will be capable of retrofit to methanol operation from 2025.MAN Energy Solutions and Alfa Laval previously collaborated on decarbonising shipping in 2014 when the very first methanol solution for two-stroke marine engines was in development. To date, this is still the only such system in use at sea with over 150…

WinGD, Alfa Laval Team to Advance Ammonia-powered Engines

Alfa Laval and WinGD established a partnership in which Alfa Laval will deliver two fuel supply systems (FSS) for testing WinGD’s ammonia-fuelled engine in early 2024, a step in the development of ammonia as a future fuel for marine vessels.Alfa Laval will deliver the FSS for the injector test system and FSS for the engine test bench in early 2024. The project is in the framework of WinGD’s and Alfa Laval's earlier agreement for cooperation on methanol and ammonia, signed in 2022.

Future Fuels: Methanol

Any commentator on the maritime business decarbonization voyage will offer something along the lines of "There will be multiple fuels…" With the International Maritime Organization (IMO) meetings of its Maritime Environmental Protection Committee (MEPC) set for early July, it is likely that targets for emissions will be tightened. Whatever mileposts that the IMO actually establishes, there will be no prescriptions handed down on how to get there. By mid-2023, nearly two years after the late 2021 alternative fuels crescendo in the aftermath of the COP26 meetings in Glasgow…

Odfjell to Install Alfa Laval's Air Lubrication System on Tanker

Odfjell Ship Management has selected Alfa Laval’s OceanGlide fluidic air lubrication system for installation on one of their tankers later this year.OceanGlide is newly acquired technology for Alfa Laval. The patented and class-approved system utilizes fluidic oscillators to generate an even layer of micro air bubbles across a vessel’s entire flat bottom, reducing friction and drag and therefore fuel consumption and CO2 emissions. The fluidic technology creates streamlined sections on the vessel’s flat bottom, each with its own fluidic band that generates bubbles.

Alfa Laval to Deliver the World’s First Methanol-Fired Steam Boiler

Alfa Laval has introduced a methanol-fired Aalborg boiler that accommodates a wide range of fuel types including LNG and methanol.It will be the first time a methanol boiler has been installed onboard a ship, and Alfa Laval has secured significant orders for the new boiler including for container ships, tankers and cruise ships. Deliveries of the methanol boilers are scheduled to commence in late 2023.Alfa Laval says its “ready boiler” concept provides a future-proof platform, allowing for easy adjustments to the existing burner and boiler pressure section as needed.

Nor-Shipping 2023 Awards Focus on Wind Developments

The winners of Nor-Shipping 2023's top awards are Swedish/Danish tanker operator Terntank, wind power pioneer AlfaWall Oceanbird and Bound4Blue Co-founder and COO Cristina Aleixendri Munoz.Expert judging panels described the competition for the accolades as “fiercer than ever”, reflecting on the “dynamic, ambitious and innovative state of an industry in transition.”Terntank secured the coveted Next Generation Ship Award for its Hybrid Tanker 15,000dwt newbuildings, currently under construction at CMHI Jinling Shipyard in Yangzhou, China.

Alfa Laval Acquires Air Lubrication Company MPS

Alfa Laval announced it has completed its acquisition of Marine Performance Systems B.V. (MPS), a Rotterdam-based maritime technology company that has developed a fluidic air lubrication system enabling reduced fuel burn and emissions..Having acquired a minority stake in MPS in 2021, Alfa Laval has now taken the final step to fully integrate the company under its own brand. The acquisition will accelerate the advancement and introduction of the patented fluidic air lubrication system…

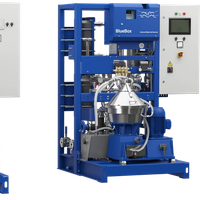

Alfa Laval Debuts Compact PureBilge

Alfa Laval announced the launch of PureBilge Compact, a compact version of the oily water separator PureBilge, designed to reduce the sytems footprint and ease install.PureBilge Compact is dseigned to be a highly compact and modular solution that provides a great opportunity for small-segment vessels to benefit from the proven oily water separation technology without space and installation constraints. Its reduced footprint and hassle-free installation also makes it an ideal retrofit solution for bigger vessels struggling with filters.PureBilge Compact is designed for 24/7 unmanned operation…

Alfa Laval Debuts Biofuel-ready Separator

Biofuels are a current and accessible fuel option that can help maritime decarbonize, and Alfa Laval becomes the first to offer biofuel-optimized separators and separator upgrades.Biofuels like HVO (hydrotreated vegetable oil) and FAME (fatty acid methyl ester) can be used by diesel engines without major engine modifications. They can be a carbon-neutral alternative if produced from the right biomass, but they must still be cleaned effectively to prevent performance issues and expensive engine wear.

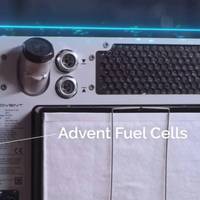

Advent Technologies Partners with Alfa Laval to Explore Fuel Cell Uses

U.S. based fuel cell and hydrogen technology company Advent Technologies Holdings, Inc. announced it will collaborate with Alfa Laval, a global provider of heat transfer, separation, and fluid handling products, on a project to explore applications of Advent’s methanol-powered high-temperature proton exchange membrane (HT-PEM) fuel cells in the marine industry.Funded by the Danish Energy Technology Development and Demonstration Program (EUDP), the project is a joint effort between Advent, Alfa Laval and a group of Danish shipowners.

Great Ships of '22: MV George III, LNG Containership

Operating on Liquefied Natural Gas (LNG) from day one in service, the MV George III, the first of Pasha Group’s two new ‘Ohana Class’, Jones Act-qualified containerships, features a state-of-the-art engine, an optimized hull form, and an underwater propulsion system with a high-efficiency rudder and propeller. George III is the first LNG-powered vessel to fuel on the West Coast and the first to serve Hawaii. The 774-ft. Jones Act vessel surpasses the International Maritime Organization (IMO) 2030 emission standards for ocean vessels.

Shell Taps Alfa Laval to Develop Gas Combustion Unit for Liquid Hydrogen Carriers

Shell International Trading and Shipping Company Limited has signed a memorandum of understanding (MOU) with Alfa Laval regarding the development of a new Gas Combustion Unit (GCU) for use on liquid hydrogen carriers.By paving the way for the safe transport of hydrogen by sea, the project is an important step on the path to global decarbonization. Crucial safety for zero-carbon fuel Under the MOU, Alfa Laval will develop a system to safely combust hydrogen boil-off gas (BOG) from a vessel’s storage tank, as part of a new liquid hydrogen carrier.

Marine News' Top Vessels of 2022

The November edition of Marine News magazine highlighted the most notable newbuilds delivered in 2022. From sturdy and nimble workboats, to the first new Jones Act laker in a generation, each vessel on display showcases the industry’s engineering prowess and technological ingenuity, with the focus on improving efficiency in operations. The maritime industry has no shortage of challenges to overcome, and each of Marine News’ top vessels will, in one way or another, aid efforts to tackle them.Mark W.

Safe Bulkers Lines Up More Scrubber Retrofits

In recent years, Greek shipowner Safe Bulkers has retrofitted Alfa Laval PureSOx exhaust gas cleaning systems on 20 of its bulk carriers. The company has just installed its 21st PureSOx scrubber, and four more retrofits are scheduled through the first half of 2023.Safe Bulkers is expanding the retrofit program for exhaust gas cleaning within its fleet. Having now retrofitted an open-loop PureSOx system on the MV Pelopidas, the company will retrofit equivalent systems on four Capesize bulk carriers: MV Aghia Sofia, MV Lake Despina, MV Maria and MV Michalis H.

New Project Aims to Capture Carbon Emissions Onboard Oil Tanker

A consortium made up of global energy and shipping organisations announced on Wednesday that they will start a project to build and test a carbon capture system onboard an oil tanker for the next two years.The project onboard a medium-range tanker owned by shipping firm Stena Bulk is targetting at least 30% absolute carbon dioxide capture, or about 1,000 kilogramme per hour, the companies said in a joint press release on the sidelines of the Singapore International Bunkering Conference and Exhibition (SIBCON) 2022.It is being carried out by the Global Centre for Maritime Decarbonisation (GCMD) in Singapore, the Oil and Gas Climate Initiative (OGCI)…

Alfa Laval to Use Fossil-free Steel in Heat Exchangers

Alfa Laval on Monday announced it has signed an agreement with Swedish steel company SSAB to develop the first plate heat exchanger made using fossil-free steel.Alfa Laval’s heat exchanger portfolio includes plate heat exchangers that are suitable for both traditional and alternative fuels. The partners aim to have the first unit made with hydrogen-reduced steel ready for 2023.“Our marine plate heat exchangers are already key to decarbonizing on board, thanks to their superior level of energy efficiency,” said Peter Nielsen, President, Alfa Laval Marine Separation & Heat Transfer Equipment.

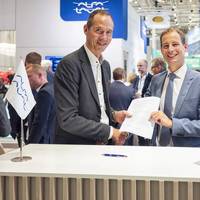

Alfa Laval and WinGD Partner on Methanol Fuel Solution

Alfa Laval and Swiss engine designer WinGD have established a joint program in which Alfa Laval will develop the fuel supply system for WinGD methanol engines. The agreement was signed on September 8 at the SMM exhibition in Hamburg, Germany.To support shipping decarbonization, WinGD has announced that its engines will be able to run on methanol as of 2024. In making that promise reality, the company has turned to Alfa Laval for the development of a fuel supply solution. Alfa…

Marine Insurance: Climate Change Challenges for the Shipping Industry

With 90% of global trade moved by sea, shipping is a major contributor to climate change. The International Maritime Organization (IMO) estimated that the industry’s greenhouse gas emissions grew by 10% between 2012 and 2018, while the industry’s share of global anthropogenic CO2 emissions grew slightly to almost 3%, about the same volume as Germany. It also forecasts that ‘business as usual’ could see emissions increase by up to 50% by 2050 due to the growth in shipping trade.The race to decarbonize shipping is now underway.

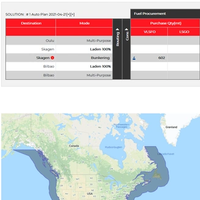

Alfa Laval Acquires BunkerMetric

Alfa Laval has signed an agreement to acquire BunkerMetric, a Scandinavian software company that develops advanced decision support tools for the marine bunker segment. The company will be merged into weather intelligence software and decision support services frim StormGeo, now part of Alfa Laval.Headquartered in Denmark, BunkerMetric helps ship operators and bunker procurement departments find the best bunker procurement plan and improve voyage margins. Using sophisticated algorithms…

Marine Insurance: Climate Change Challenges for the Shipping Industry

With 90% of global trade moved by sea, shipping is a major contributor to climate change. The International Maritime Organization (IMO) estimated that the industry’s greenhouse gas emissions grew by 10% between 2012 and 2018, while the industry’s share of global anthropogenic CO2 emissions grew slightly to almost 3%, about the same volume as Germany. It also forecasts that ‘business as usual’ could see emissions increase by up to 50% by 2050 due to the growth in shipping trade.The race to decarbonize shipping is now underway.

Alfa Laval to Provide Fuel Supply System for Six Methanol-fueled Containerships

Alfa Laval said its FCM Methanol will be the low-flashpoint fuel supply system (LFSS) on six 1170 TEU containerships ordered by Eastaway, a member of the X-Press Feeders Group. The new vessel series, to be built at Chinese shipyards Ningbo Xinle Shipbuilding Group Co., Ltd and New Dayang Shipbuilding Co., Ltd, will have two-stroke MAN B&W ME-LGIM engines that can run on methanol as well as conventional fuels. The FCM Methanol deliveries will begin in June 2023.Peter Nielsen, President…

Alfa Laval Buys Tank Cleaning Firm Scanjet

Alfa Laval has acquired Scanjet, a supplier of tank cleaning equipment and solutions for marine, offshore and industrial applications. "The acquisition will extend Alfa Laval’s broad tanker offering, creating a more comprehensive product portfolio for cargo tanks," Alfa Laval said, without sharing details on the value of the deal.According to the company, Scanjet’s intelligent tank management solutions will be a valuable complement to Alfa Laval’s sustainable marine offering as…