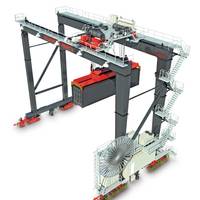

Konecranes Wins Abu Dhabi Terminal Automation Deal

Abu Dhabi Terminals (ADT) has selected Konecranes to be the supplier of an Automated Stacking Crane (ASC) system for the second phase of the building of its container terminal in Khalifa Port: the Khalifa Port Container Terminal (KPCT).This is an order for a total of 54 Automated Rail Mounted Gantry (ARMG) cranes. The parties involved have agreed not to disclose the value of the deal. The order will be booked in Q4 2018.Konecranes earlier successfully delivered 52 ARMG cranes, on time and on budget for the first phase of KPCT container terminal, which went live on 12/12/12. The second phase involves a large expansion of the terminal area, infrastructure, container handling capacity, and the delivery of 54 Konecranes ARMGs.

Latest Innovations in Heavy Duty Machinery

In the first of a series of marine industry sector reviews, MR&EN correspondent Tom Mulligan reports on the latest innovations in heavy lifting machinery technology with a selective overview of new product launches and recent equipment installations on board ships, ferries and workboats, as well as in ports, docks, harbors and shipping terminals worldwide. Markey Machinery’s Render/Recover and Asymmetric Render/Recover ‘active heave’ compensating winches have been recognized as…

Konecranes for Bharat Mumbai Container Terminals

Bharat Mumbai Container Terminals Pte Ltd (BMCT), a wholly owned subsidiary of PSA International Pte Ltd (PSA), exercised its option to purchase a further 18 Konecranes Noell Rubber Tired Gantry (RTG) cranes. This order follows upon an initial order for 18 RTG and 4 RMG cranes that will be delivered by the end of this year. The 18 RTGs currently on order will be delivered in two lots: 9 units will be delivered by August 2018, and the remaining 9 by end-2018. At this time BMCT will operate a total of 36 Konecranes Noell RTG cranes and 4 Konecranes Noell RMG cranes. The RMG cranes will be used in BMCT’s railyard, which can handle double-stack container trains up to 1.5 km long. They will be powered from the terminal’s mains and will not generate any local exhaust emissions.

Terex Floating Cranes for Open Sea Get Approval

Terex Port Solutions (TPS) has obtained design approval for Terex Gottwald Model 8 floating cranes in the G HPK 8200 B four-rope grab variant operated on the open sea. This was necessary because the Lloyd's Register Code for Lifting Appliances in a Marine Environment has changed since the initial approval of the machines in 2007. The design of the crane, which offers an outreach of maximum 50 m, a 63 t grab curve and lifting speeds of up to 140 m/min, has also been completely reworked in the meantime and adapted to the current Model 8 series standard. According to Lloyd’s Register, the G HPK 8200 B cranes can be used at wave heights of up to 2.5 m and wind speeds of up to 20 m/s.

ABP orders Two Gottwald cranes

Terex Port Solutions (TPS) has received an order from Associated British Ports (ABP) for two electric Terex Gottwald Model 8 portal harbour cranes in the G HSK 8424 B four-rope grab variant. The leading British port operator has ordered the two machines for its terminal in Immingham, located on the North Sea estuary of the Humber. The cranes have been adapted to the individual conditions of the terminal and are particularly efficient as they are driven with power from the terminal’s own electricity supply. From the middle of next year, they will significantly increase handling capacities for professional loading and unloading of bulk products.

Fiber-rope Retrofit Extends Subsea Crane Capabilities

MacGregor, part of Cargotec, has launched a fiber-rope retrofit option for its subsea cranes; the modular upgrade replaces the crane's original steel wire rope with synthetic fiber rope, using the same technology as MacGregor’s fiber-rope crane, the FiberTrac 1500, introduced earlier this year. These cranes combine MacGregor's offshore crane technology with the fiber-rope tensioning technology perfected by Parkburn Precision Handling Systems. According to MacGregor, fiber rope’s advantage when used in this context is that it weighs virtually nothing in water, so regardless of the length of rope paid out; it does not add anything to the load experienced by the crane.

Four Terex Gottwald Cranes for IRC Haldia Port

Düsseldorf, Germany, 14 June 2016 – Terex Port Solutions (TPS) is continuing its success in India with its diesel-electric Terex Gottwald mobile harbour cranes. IRC Natural Resources Pvt. Ltd., which is part of the IRC Group (IRC), has ordered two Model 4 mobile harbour cranes in the G HMK 4406 B 4-rope grab variant for its contract at Berth No. 13, Haldia Dock Complex, located to the south of Kolkata on the Ganges estuary. In August 2016, the cranes will be transported, completely erected, by heavy-load vessel to India, where they will handle coal, coke, manganese ore and limestone from October onwards. The two identical machines have a 40-t grab curve and a maximum lifting capacity of 100 t.

Korea Express Orders Two Quaymate M50 Cranes

Xiamen, People’s Republic of China, 24 May 2016 – Terex Port Solutions (TPS) notches up another success for its Terex Quaymate M50 mobile harbour crane. After the first machine in the world completely manufactured and assembled by the Chinese site of TPS in Xiamen was shipped to Australia in March this year, the leading South Korean logistics service provider CJ Korea Express (Korea Express) has now ordered two Quaymate M50 mobile harbour cranes for different terminals. In August 2016, the two 2-rope mobile harbour cranes with a maximum lifting capacity of 50 t, a 20-t motor grab curve and an outreach of up to 36 m will be commissioned in the terminals of Korea Express located in Ulsan on the East Sea and Incheon on the Yellow Sea.

Terex Port Solutions for Argentinian Power Plant

Terex Port Solutions (TPS) achieves another success in South America. The Argentinian power plant operator AES Argentina Generacion S.A. (AES) has ordered a Terex Gottwald Model 2 portal harbour crane in the G HSK 2224 variant from TPS. From the end of 2016, AES will use the cargo handling machine in its 1,540 MW power plant in San Nicolás de los Arroyos to unload coal imported from Colombia and South Africa. The G HSK 2224 crane will be the first Model 2 in the world designed as a portal harbour crane. the north west of the Atlantic estuary of the Rio Paraná. Efficient coal handling with portal-mounted mobile harbour crane technology.

Four TEREX Mobile Cranes for Asia Pacific

Terex Port Solutions (TPS) continues to systematically strengthen its position in the Asia Pacific region with four new mobile harbour cranes. Two additional Terex Gottwald Model 6 mobile harbour cranes from the large crane family, ordered earlier this year, have been in use in the Port of Napier on New Zealand’s North Island since November. On 4 December, Northport Ltd. (Northport) not only officially launched its container hardstand area, but also a Terex Gottwald Model 4 mobile harbour crane from the medium-sized crane family at Marsden Point, also situated on the North Island. Finally, the world’s first Terex Quaymate M50 mobile harbour crane from the small crane family of TPS…

‘TWIN X-STERN’ – A Stern at Each End

Is a bow really a necessity for large ships? When the vessel’s main function is walk-to-work (W2W) services in the offshore renewable sector, a heightened sterncan operateeither way,thus facilitating on-siteDP positioning.This is the idea behind the TWIN X-STERN concept vessel from ULSTEIN, which also includes new thoughts on propulsion, bridge, gangways and cranes. “The exploitation of renewable energies will become increasingly important in the post-oil era. In the future, renewable energy farms within areas such as solar, wind, wave and current will be established even further from shore in order to maximise the energy created. To serve more distant energy farms…

MacGregor Delivers Major Winch for Korean Heavy Lift Barge

Following an order announced in October 2013, MacGregor, part of Cargotec delivered and commissioned 45 variable frequency drive (VFD) winches and a full control system for the recently completed heavy-lift crane barge Hyundai HLV-10000, one of the largest heavy lift vessels in the world. Hyundai Samho Heavy Industries Co Ltd, a subsidiary of Hyundai Heavy Industries, built the large floating crane to meet the increasing demands for heavyweight shipbuilding support activities, along with offshore lifting operations. "This delivery extends MacGregor's heavy lift vessel portfolio," says Francis Wong, Head of Sales and Marketing at Offshore Deck Machinery at MacGregor.

Schmiedag and Wildauer Schmiedewerke: 'We Forge Partnerships'

Olaf Wiertz, Sales Director at Schmiedag GmbH (SDG) and Wildauer Schmiedewerke GmbH & Co. KG (WSW) said: “We are more than just a supplier to our customers – we are their partner. Based decades of experience and the accrued knowledge of its employees, SDG and WSW seek to set world standards in the forging technology. Both companies together (also including a facility in Homburg for machining) form the closed-die-forging group within the more the Georgsmarienhuette (GMH) group, which is more than 150 years old.

E-Crane Holds Technology Showcase in New Orleans

E-Crane agents and special guests attended the E-Crane Technology Showcase in New Orleans during the first week of December in conjunction with the International WorkBoat Show (IWBS). The three day event consisted of a dinner reception and presentations on the evening on Wednesday, December 3, as well as two site visits on the following days to see actual E-Cranes in operation. E-Crane guests and attendees were also given special access to the WorkBoat Show, and were able to attend the exhibit hall throughout the week.

Terex Scoops 2 IBJ Awards

Terex® Quaymate M50 mobile harbour crane is Crane of the Year – Dr. Rotterdam/Düsseldorf, 24 November 2014 – Terex Port Solutions (TPS) has been successful in two categories of this year’s awards, presented by the leading international specialist magazine International Bulk Journal (IBJ). In Rotterdam, TPS received the Crane of the Year award for its Terex® Quaymate M50 mobile harbour crane, launched in spring 2014. In addition Dr. Mathias Dobner, Vice President Development, Engineering & Operation at TPS, was named Personality of the Year. Since 2009, IBJ has presented these awards. They are considered some of the most sought-after prizes in the bulk materials handling market.

Konecranes Wins Follow-up Order from Brazilian Shipyard

In June 2013 Konecranes received a further order from Brazilian shipyard Estaleiro Enseada do Paraguaçu – EEP. The high-tech portal jib crane is scheduled to be taken into operation in August 2014. The order follows up the Konecranes Goliath gantry crane that the same customer ordered in March 2013. The parties have agreed not to disclose the value of the order, but the price for this type of crane typically is in the range of $6-8 million, depending on the exact scope of delivery. The crane will be equipped with the latest in crane technology.

GE to Deliver Crane Systems for LNG Vessel Construction

When the time came to expand Dalian Shipyard’s shipbuilding and repair facilities to build next-generation LNG tankers and container vessels, they turned to long-term partner GE Power Conversion to supply the complete drive and automation system for Goliath Crane. Over their 12-year relationship, GE has helped Dalian Shipyard to remain competitive by supplying drive and automation technology up to the latest standards, as well as by adapting its drive solutions to Dalian Shipyard’s…

Konecranes Win Record Indonesian Order

Konecranes to deliver container handling equipment to Indonesian state-owned terminal operator PT Pelabuhan Indonesia III (Persero). The order comprises 10 ship-to-shore cranes, 20 automated stacking cranes and five straddle carriers. Delivery is scheduled for 2014 and 2016. The value of the order is not disclosed, but is more than €100 million (nearly US$131-million). The Indonesian state-owned terminal operator PT Pelabuhan Indonesia III (Persero), is also known as Pelindo III.

MHI Licenses Deck Crane Technology

Mitsubishi Heavy Industries, Ltd. (MHI) signs to allow the Korean company, SPP Machine Tech, to produce & market its cranes. The deck cranes to be licensed are two models, currently on the market, having a 36-ton hoisting capacity and a working radius of up to 26 and 28 meters, respectively. MHI will supply components for the cranes, including hydraulic machinery, to SPP Machine Tech. With this initiative, MHI aims at accelerating market penetration of MHI technology-based marine deck cranes in Korea. Before this, MHI licensed the technology to Jiangsu Masada Heavy Industries Co, Ltd.

MHI Licenses Steering Gear and Deck Machinery to Jiangsu Masada

Tokyo - Mitsubishi Heavy Industries Ltd. (MHI) has signed an agreement with Jiangsu Masada Heavy Industries Co Ltd., in Jiangsu Province, China, under which MHI is to license production and marketing of steering gears and deck machinery, based on company technology to Jiangsu Masada. Previously, in 2008, MHI licensed deck crane technology to Jiangsu Masada - then known as Nantong Masada Ship Machinery Co. Ltd. With the latest licensing agreement, Jiangsu Masada will now be able to establish a structure for providing hydraulic marine machinery in combination to its customers…

Mississippi Floating Crane Fleet Expanded

Associated Terminals LLC in Louisiana/USA is expanding its fleet of machines with its seventh Gottwald Floating Crane. A Generation 5 Model 8 crane variant will be starting commercial operation this month and will be one of the highest performance Floating Cranes handling bulk materials on the Mississippi. Currently, six Gottwald Floating Cranes supplied by Demag Cranes are in operation with Associated Terminals LLC ensuring smooth, efficient cargo handling. “On the Mississippi, in particular, where quay facilities are few and far between, we intend to use the new Gottwald Floating Crane to improve our versatility in terms of midstream cargo handling”, explained Gary Poirrier, Director of Associated Terminals LLC.

Chinese MHI Licensee’s First Marine Deck Crane

Nantong Masada Ship Machinery Co., Ltd., a Chinese company located in Nantong, Jiangsu Province, to which Mitsubishi Heavy Industries, Ltd. (MHI) licensed its marine deck crane technology, has completed production and delivery of its first MHI-licensed product. Delivery was taken by Jiangsu Hantong Ship Heavy Industry Co., Ltd., a major local shipbuilder. Nantong Masada aims to increase deck crane production in response to rapidly growing demand arising from a sharp increase in local construction of cargo ships, including bulk carriers.