Bristol Harbor Group Hires Kyle Pagan

Briston. R.I. based naval architecture and marine engineering frim Bristol Harbor Group, Inc. (BHGI) announced it has hired Kyle Pagan as a naval architect.Pagan holds a Master’s degree in Naval Architecture and Marine Engineering from the University of New Orleans and a Bachelor’s degree in Petroleum Engineering from Louisiana State University. For his graduate research, he conducted an in-depth study of the performance of 3D printing materials under the influence of water exposure…

US Coast Guard Announces New Merchant Mariner Credential

The U.S. Coast Guard announced a new merchant mariner credential (MMC) set to launch on March 1, 2024, marking the first comprehensive revision of the mariner credential in nearly a decade.The Coast Guard is the exclusive source of U.S. MMCs, which are required for U.S. mariners who serve on commercially operated vessels such as passenger boats, tug and barges, offshore supply vessels, and deep draft ocean going cargo vessels throughout the nation and internationally.The Coast…

The Man Behind the 'Jones Act'

![Senator Wesley Livsey Jones (Credit: Library of Congress, Prints and Photographs Division, photograph by Harris and Ewing, [LC-DIG-hec-15427])](https://images.marinelink.com/images/maritime/w200h200c/senator-wesley-livsey-jones-credit-146310.jpg)

Senator Wesley Livsey Jones gave his name to the famous “Jones Act” governing U.S. domestic maritime trade. But what do really know about him? It turns out that he was much more than a leading merchant marine policy maker. (i)Jones had a long career in the U.S. House of Representatives before he was a Senator, was an effective legislator, an astute politician, one of the hardest working legislators of his era, and always viewed as honest and forthright. His many maritime legislative successes included the Merchant Marine Act…

3D Printed Spare Part Cuts Downtime for Wallenius Wilhelmsen's RoRo Vessel

Pelagus 3D said Wednesday it had delivered a Return Oil Standpipe at Kobe, Japan, to be installed on Wallenius Wilhelmsen's RoRo vessel TYSLA. The collaboration involved Kawasaki Heavy Industries and Wilhelmsen Ship Management.Traditionally, the procurement, fabrication, and delivery of specific spare parts has been a time-consuming process, often leading to costly downtime for the maritime and offshore industries. However, with the advent of Additive Manufacturing (AM), also known as 3D Printing…

Partners Aim to Produce 3D-printed Propeller

ABS is joining Mencast Marine (MMPL), the Singapore University of Technology and Design (SUTD), and the National Additive Manufacturing Innovation Cluster (NAMIC) on a project to manufacture and class a 3D-printed propeller.The collaborative project builds upon a memorandum of understanding (MOU) signed by ABS and MMPL that is focused on additive manufacturing (AM), also known as 3D printing, for critical maritime components.The new initiative has an objective to 3D-print a ship propeller using Wire Arc Additive Manufacturing (WAAM) techniques with a goal to achieve high-quality…

ABS Joins Korean Partners on 3D Printing Project

ABS signed a memorandum of understanding to work with key stakeholders in Korea to develop and demonstrate a 3D printing system for ocean-going vessels.Using a digital library for the design process, the system aims to support rapid maintenance, repair and operations by using 3D printing, also known as additive manufacturing (AM), to manufacture parts on a vessel while at sea.ABS joins project partners Ulsan Metropolitan City, Ulsan ICT Promotion Agency, Korea Institute of Industrial Technology…

Thyssenkrupp, Wilhelmsen Create 3D Printing Firm of Maritime & Offshore Sectors

Wilhelmsen and Thyssenkrupp announced on September 29 their joint venture company, Pelagus 3D, marking the entry of a new player into global maritime and offshore services market."Pelagus 3D envisions to be the largest one-stop, on-demand digital manufacturing partner for the maritime and offshore industries. It uses Additive Manufacturing (AM) or 3D printing to deliver maritime spare parts more efficiently in terms of time and cost, allowing customers to ensure their vessels’ seaworthiness and keep their operations moving on schedule…

NPS Research on Coast Guard Icebreaker to Enhance Arctic Readiness

During a seven-week Arctic transit aboard the U.S. Coast Guard icebreaker USCGC Healy (WAGB 20), researchers from the Naval Postgraduate School (NPS) will study the impact of the extreme environment on crew performance and potential mitigations, as well as advanced Additive Manufacturing (AM) technologies in adverse sea conditions.The studies, which commenced with Healy’s departure from Kodiak, Alaska on Aug. 26, will be led by principal investigator Dr. Nita Shattuck, a professor in the NPS Operations Research (OR) department.

Hepburn and Sons Joins Forces with MELD Manufacturing

Hepburn and Sons LLC announced it has officially joined forces with MELD Manufacturing Corporation, developer of the patented, solid-state metal additive manufacturing process and provider of MELD 3D printing machines. The companies have been working together since 2021 to introduce the Navy and other military services and DoD agencies to MELD, also known as additive friction stir deposition.Hepburn and Sons LLC is a small business founded in 2010 whose initial focus was to provide expert consulting…

3D Printing: Navy Builds Up Additive Manufacturing on Ships

The U.S. Navy has long valued the potential of additive manufacturing (AM) and 3D Printing.AM refers to the depositing of material layer by layer to create an object. For the Navy, it’s not practical to carry every replacement part for every system on a ship, and it can be difficult to forecast if or when parts will fail. AM provides a flexible source of supply in being able to make parts instead of ordering them and waiting for them to arrive, especially for warships at the far end of the supply chain.

ClassNK Journal Outlines Maritime Risk Management

ClassNK has released the latest "ClassNK Technical Journal”, which has been published for contributing to the development of the maritime industry through the outcome of R&D and technical activities.The latest issue, “ClassNK Technical Journal No.6 2022 (II)” features how to deal with risk, including articles on risk assessment in the maritime sector, the concept of vulnerability which contributes to developing a new framework that supports the social implementation of Maritime Autonomous Surface Ship (MASS), and fundamentals and applications for risk-based ship design.In addition, it also inc

Attention Turns to Extra Large Unmanned Underwater Vessels

In August, 2021, after years of delays, cost overruns, and rising tensions, the Australian government canceled a A$90 billion order with France’s Naval Group for 12 conventionally powered submarines intended to replace the Royal Australian Navy (RAN)’s aging fleet of six Collins-class attack subs. Overnight, the future of the RAN’s undersea warfare capability was cast into uncertainty. The very next month, however, the United States and the United Kingdom announced a plan to help Australia fill the void…

Navy: Using 3D Scanning to Reverse Engineer

“We are trying to reduce not only our time to start a design, but we want to have a good design the first time. We want to eliminate any rework that would cost us time and money later in our program schedule,” said John Moser, Hardware and Metrology Engineer from Weapons Control and Integration, referring to the latest technological advance, using 3D scanning as a reverse engineering capability. Naval Surface Warfare Center Dahlgren Division has begun to use this process to provide…

ChartWorld Suspends Services to Russian Vessels and Companies

Following the Russian invasion of Ukraine, ChartWorld has announced the suspension of ECDIS, chart, and navigation data services to Russian-owned and managed vessels. Current vessels will be provided with chart updates to allow them to reach the next port safely but have been asked to find new suppliers for all future voyages. The group's other companies, including navigation and ENC software development company SevenCs, have also suspended all projects and software deliveries to Russian companies and vessels.Steven Schootbrugge…

Choose Wisely: A Deep Dive into Domestic Passenger Vessels SMS Proposed Rulemaking

On January 15, 2021, the U.S. Coast Guard issued an Advanced Notice of Proposed Rulemaking (ANPRM) for Safety Management System (SMS) requirements in the domestic passenger vessel industry (Docket No. USCG-2020-0123). This requirement will have the largest implications on the domestic passenger vessel industry since the revisions of 46 CFR Subchapter T & K in the mid-90s. However, the question remains, is it necessary?Over the last three decades, the effectiveness and need for…

ABS Publishes Guide on 3D Printing

Classification society ABS has published guidance on the application of additive manufacturing (AM) in the marine and offshore industries.The ABS Guide for Additive Manufacturing focuses on two main categories of metal AM processes: Powder Bed Fusion and Directed Energy Deposition. The Guide defines the ABS approval and certification process for AM facilities and AM parts by providing standards for AM design, feedstock material, building processes, inspection and testing. The Guide includes a strong focus on the quality of the materials and of the manufacturing process…

ClassNK Publishes 3D Printing Guidelines

Classification society ClassNK released its “Guidelines for Additive Manufacturing(3D Printing)” that summarize the approval requirements for metallic marine equipment by additive manufacturing technology.Additive manufacturing, also know as 3D printing, is a method for manufacturing by laminating and combining materials such as resin and metal based on 3D model data. Its feature is the capability to mold complex and high-precision shapes.In recent years, the use of additive manufacturing technology has been rapidly expanding in manufacturing metallic products…

ABS Approves 3D Printed Spare Parts After Tanker Trial

Parts fabricated by additive manufacturing (AM) – also known as 3D printing – and installed on an oil tanker for operational testing have been validated to be in good working condition, marking a significant step for the technology's implementation in the marine industry.The project involving ABS, ConocoPhillips Polar Tankers, Sembcorp Marine Ltd and 3D Metalforge started in February 2021 with the fabrication and lab-testing of functional additive manufactured parts, which were then installed on board the oil tanker Polar Endeavour.

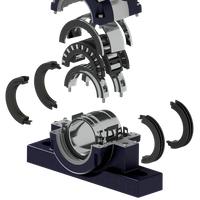

Bowman Debuts Higher Capacity Split Roller Bearing

U.K.-based Bowman International said it has launched to market a split roller bearing with substantially higher radial and axial load capacities. Suited for applications such as propulsion shafts and electric motors, the new Bowman Advanced Split Roller Bearing offers up to 75% higher radial load capacity and up to a 1000% increase in axial load capacity in both directions, the manufacturer said.“For the first time, shipbuilders and vessel maintenance engineers can specify a split roller bearing that does not rely on race lips alone to accommodate axial force in high-load applications…

Interview: Hiroaki Sakashita, CEO, ClassNK

While the maritime industry faces a long ‘to do’ list for the coming three decades, Hiroaki Sakashita, CEO, ClassNK, sees decarbonization as the definitive trend that will most dramatically impact the design, construction and life-cycle operation of ships.“It is decarbonization.”Hiroaki Sakashita, CEO, ClassNK, is definitive when asked to discuss the biggest challenge facing shipowners today. “Decarbonization will change the structure of seaborne trade, ships’ specification and design, ships’ operation, and the economic mechanism of maritime transportation.

DNV Awards Type Approval for 3D Printing Feedstock

Voestalpine Böhler Welding Germany GmbH has become the first manufacturer worldwide to be awarded a Type Approval certificate from classification society DNV, for their solid wire 3Dprint AM 70/I1 feedstock. The Type Approval has been awarded based on DNV’s new class programme, DNV-CP-291 “Additive Manufacturing Feedstock”.The Type Approval certificate was presented to voestalpine Böhler Welding Germany GmbH during the DVS Congress held in Essen, Germany, and is the first of its kind to be issued by a classification society.

Connectivity Key to Seafarer Welfare, Inmarsat Sponsored Report says

Inmarsat sponsored a new report which explores the future of seafaring to 2050, a report that offers not just insights on connectivity, rather recommendations on how shipping, training institutions and welfare services can respond to the changing needs of tomorrow’s seafarers.Dubbed ‘A fair future for seafarers?’, the report was prepared by maritime consultancy Thetius. While published as the world still struggles with the impact of COVID-19, the report suggests epidemics and pandemics may become more common…

Huisman Scales Up 3D Printing

Cranes manufacturer Huisman said it has successfully tested four new 3D printed 350mt crane hooks under the supervision of the independent certification authority Lloyd's Register.The hooks are approx. 170 by 130cm in size, almost nine times larger than the first Huisman 3D printed crane hook, the company said. They have a weight of 1,700kg each and a loading capacity of 350mt. Each hook exists of approx. 90 kilometers of welding wire.Huisman has been employing the 3D printing…