How Life Extension and Conversion Redefines “Born Again” in U.S. Ship Repair

We are well into the discussions advising shipbuilders and operators how the U.S. will create a renaissance of the maritime industry. Federal Legislation, Executive Orders, and new foreign partnerships driving the promise of commercial competitiveness with the leading global shipbuilders. Most of the shipbuilding rhetoric indicates the domestic markets will be left to survive on their own. This despite the fact the domestic operators and builders have proven to be the strongest…

Mitigating Deadly Maritime Risk: Inside AWO’s Falls Overboard Prevention Report

Falls overboard remain the leading cause of fatalities in the U.S. tugboat, towboat, and barge industry, a sobering reality that the American Waterways Operators (AWO) has been working to reverse for decades. Now, with the release of its comprehensive Falls Overboard Prevention Report, AWO and its partner are charting a data-driven path to help reduce this risk.The report, produced under the Coast Guard–AWO Safety Partnership, builds on decades of collaboration between regulators and industry leaders…

ABS Issues AIP for Floating Nuclear Power Module

ABS issued approval in principle (AIP) to HD Hyundai Heavy Industries (HHI) and HD Korea Shipbuilding & Offshore Engineering (HD KSOE) for a concept of a floating small modular reactor (SMR)-powered power module.The design is intended to generate electricity offshore and near shore, supporting port facilities and onshore communities. ABS completed design reviews based on the ABS Requirements for Nuclear Power Systems for Marine and Offshore Applications.The AIP is the second for…

First of Its Kind LCO2 Barge Design Approved for U.S. Operation

ABS awarded approval in principle (AiP) to Overseas Shipholding Group, Inc. (OSG), the parent company of Aptamus Carbon Solutions, for its preliminary design of a liquefied carbon dioxide (LCO2) barge.The development of the barge design is a core component of the Tampa Regional Intermodal Carbon Hub (T-RICH) project to receive, store and process emissions from Florida industries for transport to regional sequestration sites.The articulated tug and barge unit (ATB) is a first-of-its-kind to service carbon capture projects in the U.S.

ABS Approves US' First Ammonia Bunker Barge

The initial design for a new ammonia bunkering articulated tug-barge (ATB) has been granted approval in principle (AIP) from classification society the American Bureau of Shipping (ABS).The partners behind the project, including ABS, A.P. Moller – Maersk A/S, Fleet Management Limited, Georgia Ports Authority, Maersk Mc-Kinney Moller Center for Zero Carbon Shipping (MMMCZCS), Sumitomo Corporation and TOTE Services, came together in March 2023 and have been conducting a feasibility study on ship-to-ship bunkering of reduced emission ammonia along the U.S.

Tidewater Plans to Order New Liquid Product Barges

Tidewater, a provider of marine transportation and terminal services on the Columbia Snake River System, revealed plans to invest in up to four new refined liquid products barges.The Vancouver, Wash. based company said its board of directors has approved the barge design and is progressing toward the construction phase. The new barges will replace older, less efficient assets, enhancing fleet safety, efficiency and environmental stewardship, Tidewater said."Our investment in these…

Wärtsilä Partners Up with EBDG to Reduce Port Emissions Across North America

Finnish technology group Wärtsilä has entered into a collaboration agreement with U.S.-based naval architecture and marine engineering firm Elliott Bay Design Group (EBDG) to further develop its Clean Harbor Alternative Mobile Power (CHAMP) Barge design.Featuring Wärtsilä’s methanol engine technology, the collaboration introduces a solution to reduce emissions from large vessels in situations where conventional shore power is limited or not available.The floating mobile power…

EBDG Power Barge to Feature Wärtsilä Dual-fuel Methanol Engine

Wärtsilä announced it is teaming up with Elliott Bay Design Group (EBDG) to advance EBDG’s Clean Harbor Alternative Mobile Power (CHAMP) Barge design.This partnership introduces a cost-effective solution to reduce emissions from large vessels in situations where traditional shore power is not available and features Wärtsilä's dual fuel methanol engine technology, the partners said.The floating mobile platform offers a power range of 6 to 16 Megawatts, utilizing green methanol as its source.

Making Hydrogen Work: Demo Project in San Francisco Port

Hornblower Energy LLC, in partnership with the Port of San Franciso, the U.S. Department of Energy and six corporate partners, including Air Liquide and Glosten, is leading a project to demonstrate the feasibility and viability of using hydrogen (H2) as a maritime fuel.The project is located at Pier 68 in San Francisco. DOE selected the project for funding in 2020. It’s supposed to be completed in 2025 but there are important decision dates before then. So far, project activities have concentrated on planning and modeling.

EBDG Unveils Harbor Power and Charging Barge Design

Seattle-based naval architecture and marine engineering firm Elliott Bay Design Group (EBDG) last week unveiled the design for a new barge engineered to offer power and charging to vessels in ports and harbors.Delivering 7 megawatts (MW) of continuous power generated by methanol, the 225-foot-long floating mobile platform is capable of cold ironing to minimize emissions from large vessels both at the pier and at anchor for up to two weeks before refueling.In addition, it offers double duty as an "in-field" DC charging station for electric harbor tugs and other smaller service vessels.

Centerline Logistics and Vard Marine to Design LNG Bunker Barge

U.S. marine petroleum transportation company Centerline Logistics has signed a letter of intent (LOI) with naval architecture and marine engineering firm Vard Marine to develop a customized 6,000-cubic-meter-capacity articulated tug and barge (ATB) liquefied natural gas (LNG) bunker barge.Aiming to meet the shipping industry's growing need for LNG bunkering, the Jones Act-compliant ATB barge will be designed to navigate U.S. and International waters and to provide LNG refueling to a variety of ships as well as call at terminals.

Bay Shipbuilding to Build Second LNG Bunker Barge for Polaris

Fincantieri Bay Shipbuilding announced Wednesday it will build a second liquefied natural gas (LNG) bunker barge for PNE Marine Holdings, an affiliate of Northstar Terminals subsidiary Polaris New Energy. The new 5,500 cubic meter (CBM) capacity barge will be a sister to Clean Canaveral, which is scheduled to be delivered to Polaris in mid-November.The maritime sector is seeing growing demand for economical supply of LNG fueling, with more than 400 new vessels utilizing the cleaner…

Conrad Delivers First of Four Spud Barges for McDonough

Conrad Shipyard said it has delivered the first of four ABS-classed spud barges to McDonough Marine Service, headquartered in Metairie, La.The identical spud barges each measure 180’ by 54’ by 12.5’, have deck strength of 2,500 pounds PSF, and four spud wells. The remaining barges are on schedule for delivery in the third and fourth quarters of 2021. The barges are being constructed at Conrad’s Deepwater South facility in Amelia, La., one of five Conrad shipyards located along the Louisiana/Texas Gulf Coast.Patrick M.

Southwest Shipyard Delivers 250-foot Tank Barge

Houston's Southwest Shipyard has delivered a 250’ x 54’ x 12’-6”, 23,000 BBL tank barge that will primarily be used to deliver jet fuel to support the U.S. Navy assets.The Shearer Group, Inc. (TSGI) said it was contracted by the builder to develop the barge design.The barge was designed to ABS Rules for Building and Classing Steel Vessels for Service on Rivers and Intracoastal Waterways and applicable rules by the U.S. Coast Guard for barges Subchapter D & O products on rivers.

AG&P Invests in Kanfer Shipping, Eyes LNG

Global downstream gas and LNG logistics company Atlantic Gulf & Pacific (AG&P) has made a strategic equity investment in Norway-based Kanfer Shipping.Kanfer is a developer of small-scale LNG sea transportation, maritime break-bulk solutions, floating storage facilities as well as LNG bunkering. Together, Kanfer and AG&P will make LNG more accessible and commercially viable for downstream customers in new and growing natural gas markets."Kanfer has captured the attention of the global LNG maritime infrastructure industry with its patented, barge design that makes breaking bulk cargoes of LNG easier, faster and more efficient," said a…

OT&BE joins Hyperion Marine Engineering Group

Ocean Tug & Barge Engineering Corporation, a naval architecture and marine engineering firm specializing in AT/B or Articulated Tug/Barge design announced that it is now a member of the Hyperion Marine Engineering Group headquartered in Portland, Maine with offices in India, Dubai, Norway and the Netherlands.CT Marine & Buoyancy Consultants formed Hyperion three years ago recognizing a need for an integrated naval architectural & marine engineering firm to serve the inland and offshore tug and barge industry that incorporates a capability for conceptual through highly detailed production design, all under one corporate roof. With over seventy engineers who span the globe…

Unique Barge-ferry Delivered in Canada

At the completion of its 1,000 km drive along the highway from Edmonton to Hay River and the 850 km sail down the Mackenzie River to Norman Wells, the Aurora Yukon was delivered to its owner by the builder Waiward Steel LP of Edmonton, AB. The Aurora Yukon will operate with an existing tug, to carry vehicles and passengers across the Mackenzie River at Norman Wells. The Aurora Yukon replaces an existing barge which was originally built in 1969. The barge was designed by Robert Allan Ltd.

Wison Granted AIP for Its Innovative Floating LNG Storage

Wison Offshore & Marine announced that it has received Approval in Principle (AIP) from Bureau Veritas for its newly-developed large-scale Floating LNG Storage and Regasification Terminal. Featuring scalable storage capacity up to equivalent size of a Q-Max, this is the first large-scale FSRU barge design that has been granted AIP by a classification society. It also marks that Wison is now capable of providing comprehensive range of FSRU solutions catering LNG import markets with various scales of demand. This full-size floating LNG terminal solution offers an economical alternative to the conventional LNG regasification vessels (LNG RV) especially for markets with long-term demand.

McDonough Launches M 2820 Barge

McDonough Marine Service has launched its latest barge design series at the Westport Orange Shipyard in Orange, Texas. The M 2820 (282’L x 54’W x 12’6”H, with 3,000 lbs/sq.ft. deck load rating) was delivered on-schedule, and is expected to bring greater possibilities to Project Cargo transportation on the inland waterways. “As growth continues to develop in the infrastructure, petrochemical and power generation markets, the engineered components and modules are increasing in both size and weight,” stated Pat Stant, President of McDonough Marine Service.

LNG as Fuel: Challenges & Opportunities

Environmental regulations are the main driver in reducing these emissions worldwide. Although until recently ECA zones were limited to a few areas, the IMO has now decided to limit SOx emissions worldwide and by 2020 all newbuilds will have to comply with its new regulations. The challenge for the shipping industry, however, is not only to comply with the IMO 2020 sulfur cap but also to catch up with the planning of the regulation by identifying and implementing the solutions…

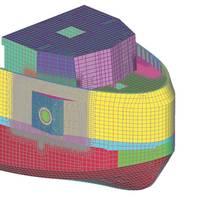

Finite Element Strength Analysis for ATB Load Box

The loading and response dynamics of an Articulated Tug & Barge (ATB) load box are complex. They typically require advanced finite element analysis methods and procedures to design an efficient support structure to ensure a durable design and to facilitate meeting Class strength requirements. To study the dynamic response of the loads imparted on the tug from the barge, a finite element analysis (FEA) is carried out. Loading conditions that include the static sea pressure, gravity loads, and reaction forces from the ATB Coupler are incorporated into the FEA analysis.

Tug-Barge Design Optimized for South America

Some veteran Mississippi pushboats and barges have been transported to South America for second careers. However, conditions on a great river like the Paraguay-Paraná are different. It has sharp bends, shallow stretches, and includesremote reachestotally lacking in infrastructure. Building on extensive experience designing for the shallow rivers of Canada's frontiernorthland, Robert Allan Ltd., Naval Architects from Vancouver, BC have taken on the challenge of creating a new generation of specialized tug and barge systems to suit these demanding environments. A waterway logistics corporation, Hidrovias do Brasil, was the firm's first South American client to commission new purpose-built shallow draft vessels.

“Green” Inland Midstream Refuel Barge Delivered

John W. Stone Oil Distributor, LLC is taking delivery of its first “green” inland midstream refueling barge from Tres Palacios Marine in Palacios, Texas. The 160 x 54-ft. double hull barge is the latest addition to the fleet of equipment Stone Oil uses to support its customer base as well as its various terminal operations. Stone Oil discussed ways to improve the existing midstream fuel barge design with its marine personnel as well as its shore based maintenance staff. This was coupled with requests from customers to provide a means to deliver various grades of fuel…