Jan De Nul Unveils ‘Most Advanced’ Wind Farm Installation Simulator

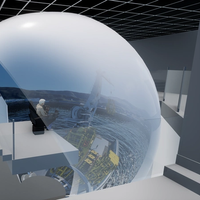

Belgium’s Jan De Nul is commissioning what it calls its most advanced offshore wind installation simulator, a digital twin of its vessels Les Alizés and Voltaire designed to train crews to install the latest generation of giant wind turbines and foundations at sea.The crane simulator, installed at the company’s Aalst office, features a seven-meter-wide dome offering a 360-degree view and allows operators to rehearse complex installation operations at heights exceeding 150 meters.Wind turbine tip heights now reach 300 metres…

US Port Strike Throws Spotlight on Big Union Foe: Automation

A strike by dockworkers on the U.S. East Coast and Gulf Coast that disrupted much of the nation's ocean shipping this week ended on Thursday, but a key issue driving labor unrest across the continent - the growing use of automation - was unresolved.Companies view automation as a path to better profit while unions see it as a job-killer. For North American dockworkers battling automation, Europe's port worker contracts may point a way to resolve the issue.Some 45,000 port workers…

Dredging Expected During Desperate Times

Maintaining a nine-foot channel on the Mississippi River is part of the U.S. Army Corps of Engineers Rock Island District’s critical navigation mission, especially during low-water conditions. Although early spring snowmelt caused flooding throughout the upper Midwest this past year, water levels receded quickly, causing large amounts of material to settle in the channel.To aid in channel maintenance, geological surveyors regularly monitor water levels throughout the District.

Career Moves: US Offshore Wind Powering Up

In addition to wind, offshore wind demands human energy, individuals with knowledge and skills first to build and then operate and maintain the dozens of projects required to meet President Biden’s 2030 goal of 30 GW of offshore generation. In an October 2022 National Renewable Energy Laboratory report – “U.S. Offshore Wind Workforce Assessment” – the authors estimate that it will require, on average, between 15,000 and 58,000 employees annually, depending on domestic content scenarios, to build out a huge new wind machine.Mariners and mariner training are integral to offshore wind.

Jan De Nul Group Orders Crane Simulator for Next-Gen Offshore Installation Vessels

Offshore installation specialist Jan De Nul Group has ordered a high-end crane simulator for two of its Next Generation Offshore Installation Vessels Voltaire and Les Alizés.According to Jan De Nul, the crane simulator will be based on real physics and the actual vessel models, enabling Jan De Nul to train its crewmembers and realistically simulate complex offshore installations in a completely safe environment, in the most severe conditions. The partner for the development of this simulator is the Norway-based company OSC AS (previously known as Offshore Simulator Centre).

Kongsberg Digital Bags 5-year Extension with Heerema Marine Contractors

Dutch offshore installation and construction firm Heerema Marine Contractors (HMC) has renewed its Long-Term System Support Program (LTSSP) contract with Kongsberg Digital for another five years.The LTSSP is in support of a K-Sim Offshore Crane simulation system, which features digital twins of HMC’s semi-submersible construction vessels, ships, and barges. HMC’s simulation center is located at the HMC headquarters in Leiden, the Netherlands."Renewal of the LTSSP ensures Kongsberg Digital’s continued commitment to maintaining Heerema’s simulators at the leading edge of available technology…

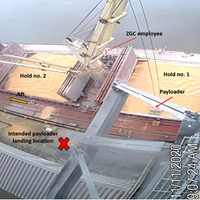

Lack of Signalman Led to Bulker Crane’s Contact with Grain Facility - NTSB

The absence of a dedicated signalman likely led to a bulk carrier’s crane striking a grain facility in Convent, La., in 2020, the National Transportation Safety Board (NTSB) found.The contact occurred on November 11, while the bulk vessel GH Storm Cat was completing corn loading operations at the Zen-Noh Grain Corporation facility with its number 1 crane boom. The vessel’s crew was removing a payloader from the number 1 cargo hold, which had been filled. A Zen-Noh Grain Corporation employee attached the crane hook to the payloader and then walked out of view of the crane operator.

Severe Winds Cause Ship Breakaway, Damage at Port in New Orleans -NTSB

Severe, unforecasted winds caused a containership to breakaway from a pier and damaged equipment at the Napoleon Avenue Container Terminal in New Orleans on Aug. 2, 2020, according to the National Transportation Safety Board.As longshoremen loaded and unloaded cargo from containership CMA CGM Bianca a sudden, localized thunderstorm passed through the area. Ten of the vessel’s 16 mooring lines parted in the high winds, and the ship moved away from the pier. Containers lifted by shoreside gantry cranes struck the ship. One damaged container dropped in the water spilling a cargo of plastic pellets, known as nurdles. A crane operator suffered a minor injury.

Ampelmann, C-Job Develop Motion-compensated Feeder Vessel for U.S. Offshore Wind Sector

Dutch offshore gangway services firm Ampelmann and C-Job Naval Architects have teamed up to develop what they say is "a one-of-a-kind" offshore wind feeder vessel concept with motion compensation technology.According to the duo, the vessel would be specifically suited for the rigorous demands of operating off the U.S. east coast.The concept design combines the knowledge of Ampelmann, the Dutch offshore access provider, and independent ship design company C-Job Naval Architects.

Interview: Heavy Lifting with John DiMartino and Tandemloc

Starting from his father’s basement in Bayport, New York, John DiMartino and his brother Bill have built a custom, heavy lift powerhouse in Tandemloc. It’s a story of building something from nothing; a story of plotting a path and adjusting for multiple course changes along the way. Ultimately, it’s a story of engineering ingenuity and heavy lift success.When John DiMartino graduated from SUNY Maritime in 1980 with a BS Marine Transportation Management, his career path started as projected…

SC Ports Constructs New Container Terminal

South Carolina (SC) Ports has celebrated the structural completion of the operations building at Hugh K. Leatherman Sr. Terminal, a new container terminal along the Cooper River, which will open in March 2021.S.C. Ports celebrated today the structural completion of the terminal’s new operations building. More than 300 people — contractors, port employees, elected leaders and community members — cheered as a steel beam and tree were placed atop the steel structure as part of a traditional “topping out” ceremony.The 34,853-square-foot building, built by Samet Corp., will have offices, meeting spaces, crane operator rest and training areas, and a full-service kitchen, as well as the backup power required to maintain critical infrastructure in the event of a power outage.Sen. Hugh K.

APM Terminals Pipavav Boosts Efficiency

The implementation of a range of simple measures to streamline shift changes at APM Terminals Pipavav has reduced vessel idle times, added capacity and reduced impact on crane moves per hour due to shift change by around 16%.At the same time, it has also improved trailer driver and crane operator safety, said a press release from APM Terminals, an international container terminal operating company headquartered in The Hague.The Pipavav team has introduced clearly marked parking bays for terminal trailers, which provide a safe distance between each trailer. This provides drivers with a safe area to conduct per-operation checks and protects them from other vehicles when exiting their trailers.

Interesting Launch for Interesting Tugs

The ownership of the Canadian firm Island Tug and Barge has changed with the purchase by the U.S. parent company Tidewater Inc. The firm is now known as Island Tug.The second tug, with the hull and superstructure completed and with the Cummins K38s installed still requires more work, was also launched in early May of 2018.The vessels were built in a warehouse on the Fraser River. With no launching facility and a railway track between the yard and the steep bank of the river, it took some innovative heavy lifting.

Latest Innovations in Heavy Duty Machinery

In the first of a series of marine industry sector reviews, MR&EN correspondent Tom Mulligan reports on the latest innovations in heavy lifting machinery technology with a selective overview of new product launches and recent equipment installations on board ships, ferries and workboats, as well as in ports, docks, harbors and shipping terminals worldwide. Markey Machinery’s Render/Recover and Asymmetric Render/Recover ‘active heave’ compensating winches have been recognized as…

MedPort Tangier Cranes to Reach APM Soon

The first group of three, of a total of 12 advanced remotecontrolled ship-to-shore (STS) cranes, has departed China for delivery on February 15 to the new APM Terminals MedPort Tangier, Morocco terminal. Manufactured by ZPMC in Shanghai, the super post-Panamax cranes will be able to accommodate 20,000 TEU vessels, giving the facility an annual container throughput capacity of five million TEUs. “Our goal is to use proven technology to create highproductivity for our clients on one of the world’s most strategically important trade lanes on the Strait of Gibraltar,” said APM Terminals MedPort Tangier Managing Director Dennis Olesen. Scheduled to become operational in 2019…

Tech File: Bulk Barge Cargo Transfer Systems Solution

Pontchartrain Materials Company finds innovative solution for barge unloading applications. Located in New Orleans, La., Pontchartrain Materials Corporation, LLC provides aggregates to general contractors as well as asphalt and ready-mix companies. In addition to their chief product, limestone, the family-owned company sells recycled concrete and recycled asphalt. Pontchartrain sources the material from quarries in northern states, transferring it down the Mississippi River by barge to one of three company aggregate yards or directly to customers in the New Orleans and surrounding area.

APM Terminals on Trends in North America

North American ports must adapt to changes in customer demand and future industry trajectory, said APM Terminals head of Hub Terminals, Jack Craig. “The customer landscape has changed and become much more competitive. We as an industry need to work together, adapt and respond or watch the cargo move elsewhere,” according to Craig. The vessel alliances now reshaping the industry have been a success for ocean carriers and their quest for cost savings, asset efficiency and economies of scale. “Larger alliances, larger vessels and larger port call volumes per ship are a catalyst to improve performance at ports. In Elizabeth, New Jersey – APM Terminals is one of the largest container terminals in the Port of New York & New Jersey port complex…

New Container Spreader from Tandemloc

For years mechanical container spreader frames have been a fixture on jobsites, river ports and any other location that utilizes ISO shipping containers. While container lifting frames are well worth their size and weight in operational cost savings, they often eat into those very savings because of the expensive shipping methods firms must utilize to get the frames on site for use. In response to this problem, Tandemloc has designed and fabricated the N3100SF Modular Autoloc Container Spreader for ISO Container Lifting.

Konecranes for Bharat Mumbai Container Terminals

Bharat Mumbai Container Terminals Pte Ltd (BMCT), a wholly owned subsidiary of PSA International Pte Ltd (PSA), exercised its option to purchase a further 18 Konecranes Noell Rubber Tired Gantry (RTG) cranes. This order follows upon an initial order for 18 RTG and 4 RMG cranes that will be delivered by the end of this year. The 18 RTGs currently on order will be delivered in two lots: 9 units will be delivered by August 2018, and the remaining 9 by end-2018. At this time BMCT will operate a total of 36 Konecranes Noell RTG cranes and 4 Konecranes Noell RMG cranes. The RMG cranes will be used in BMCT’s railyard, which can handle double-stack container trains up to 1.5 km long. They will be powered from the terminal’s mains and will not generate any local exhaust emissions.

Aircraft Carrier John F. Kennedy Half Complete

U.S. shipbuilder Huntington Ingalls Industries (HII) said the structure of nuclear-powered aircraft carrier John F. Kennedy (CVN 79) is now 50 percent complete. The second Gerald R. Ford-class aircraft carrier CVN 79 grew about 70 feet in length with the addition of the lower stern, which was recently lifted into place at HII’s Newport News Shipbuilding division. Like Ford, which was delivered to the Navy earlier this month, Kennedy is being built using modular construction, a process where smaller sections of the ship are welded together to form larger structural units (called “superlifts”)…

Training Program Seeks to Develop Alaskan Shipbuilders

A new shipbuilding and repair training program in Alaska aims to develop an advanced manufacturing workforce comprised of state residents. Shipbuilder and repairer Vigor has teamed up with the maritime workforce development network Maritime Works for a public, private and philanthropic initiative called Advancing Alaskan Workers, which will train Alaska’s next generation of advanced manufacturing workers. The initiative strives to combat the high turnover rates seen at Vigor’s Ketchikan shipyard and elsewhere that result when non-Alaskans are recruited to fill the state’s critical skills gap.

US Awards $4.85 Mln for Waterways Projects

U.S. Transportation Secretary Anthony Foxx today announced $4.85 million in grants to six Marine Highway projects along the waterways of 17 states and the District of Columbia. The goal of the Maritime Administration’s Marine Highway Program is to expand the use of U.S. navigable waterways to relieve landside congestion, reduce air emissions and generate other public benefits by increasing the efficiency of the surface transportation system. “These grants will help us take advantage of the economic and environmental benefits of one of America’s most crucial transportation assets – our coastal and inland waterways,” Foxx said. The grants will help expand existing marine highway operations across New York Harbor…

APM Orders 12 STS, 32 ARMGs Cranes

APM Terminals has announced orders for 12 remote-controlled Ship-to-Shore (STS) cranes and 32 Automated Rail-Mounted Gantry Cranes (ARMGs) to equip the new five million TEU* APM Terminals MedPort Tangier facility now under construction at the Tanger-Med II port complex. The container terminal will be the second operated by APM Terminals at the Tanger-Med port complex designed to serve the newest Ultra-Large Container Ships (ULCS) with capacities up to 20,000 TEUs. APM Terminals MedPort Tangier will have up to 2,000 meters of quay length and increase the Tanger-Med complex’s overall capacity to over nine million TEUs. The facility complements APM Terminals Tangier which handled 1.7 million TEUs in 2015.