Ammonia-powered Tug Conversion Underway

A first-of-its-kind ammonia-powered, zero-emission tugboat will be put to the test by Brooklyn, N.Y-based startup Amogy in late 2023.

Having already successfully demonstrated its technology on an aerial drone, tractor and semi-truck, the ammonia power solutions company revealed in early March that it is retrofitting a scaled up 1-megawatt (MW) version of its ammonia-to-power system onto a tug at Feeney Shipyard in Kingston, N.Y. as a test run for its emissions-slashing power and propulsion technology in the commercial maritime sector.

Once installed, Amogy’s onboard solution will feed liquid ammonia through its cracking modules integrated into a hybrid fuel cell system that will provide zero-carbon power to the vessel’s electric motors. Ammonia, which does not emit CO2 when used as a fuel, has been gaining interest in the maritime industry as stakeholders explore options to decarbonize vessel operations. Green ammonia produced with renewable energy results in zero well-to-wake greenhouse gas emissions.

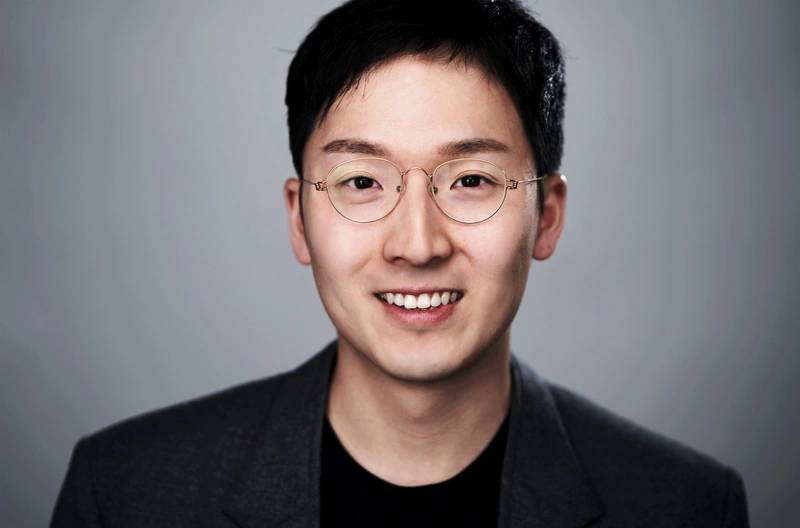

“There are different renewable energy options to decarbonize many different mobility applications. For example, batteries are a solution to electrify consumer vehicles, which is possible because you can always recharge the vehicle overnight. However, maritime vessels require very high energy density when it comes to fuel,” said Seonghoon Woo, CEO of Amogy. “Therefore, the industry really needs a renewable fuel that is highly energy dense in its liquid phase.”

Woo founded Amogy in 2020 alongside three fellow MIT PhD alumni. To date, the company has raised $209 million in funding, including $139 million announced on March 22 through a Series B-1 fundraising led by SK Innovation with global investors such as Temasek, Korea Zinc, Saudi Aramco’s Aramco Ventures, AP Ventures, MOL PLUS, Yanmar Ventures, Zeon Ventures and DCVC. Amazon’s Climate Pledge Fund has also invested in the company.

“[The tug conversion] is the first milestone of many you will see from Amogy in accelerating the accessibility and scalability of clean energy in the global maritime industry,” Woo said, noting the tug will be trialed later this year ahead of targeted commercialization in 2024.

(Image: Amogy)

(Image: Amogy)

The vessel being used for the retrofit and trials is a 105-foot tugboat built in 1957 and previously used to transport petroleum products. Asked why the vessel was chosen, Woo said, “The technical reason, first of all, is that the vessel is equipped with an electric powertrain, which we can benefit from because our technology is also generating electric power—not using diesel, but using ammonia as a fuel. . . The second reason is that the size works perfectly with our scale-up plan.” The tug’s 1 MW system will be roughly three times more powerful than Amogy’s previous trial system in the semi truck.

Feeney Shipyard, from whom Amogy sourced the tugboat, is leading retrofitting construction, engine removal and more under supervision of C-Job Naval Architects, the Netherlands-based independent ship design company integrating the ammonia system. Other partners contributing to the project include Norwegian electrical systems integrator Seam, which will deliver the power system, integrated automation system and safety system through its e-SEAMatic brand, as well as a battery system and electrical motor for main propulsion. Also involved is Unique Technical Solutions (UTS), the U.S.-based electrical and systems integrator from Amogy's prior demonstrations, for the electrical and systems work involved in scaling up the powerpack for pre-commercial use.

The vessel's new fuel tanks will be based on existing ammonia cargo tanks and fill roughly the same space previously carved out for diesel storage, Woo said. “But we are increasing the tank size by probably 20% or 30% to accommodate more fuel,” he added. Power and voyage endurance capabilities will be nearly equivalent to those of the diesel-powered tug, and Amogy’s system will be able to provide a continuous power for about 8 to 10 hours.

Norway’s Yara Clean Ammonia (YCA), one of the world’s largest ammonia producers, and the largest trader and shipper of ammonia around the world, will provide green ammonia for the demonstration. YCA is currently building an ammonia bunkering network in Scandinavia with the first bunker barge scheduled to enter service in 2024. The project partners are still working out how Amogy’s converted tug will be bunkered, whether from a barge-based or shoreside solution.

“Vessels built today will be on the water for another 20 or 25 years at least, so we have to start the decarbonization cycle today to reach our goal by 2050.” - Seonghoon Woo, CEO, Amogy (Photo: Amogy)

“Vessels built today will be on the water for another 20 or 25 years at least, so we have to start the decarbonization cycle today to reach our goal by 2050.” - Seonghoon Woo, CEO, Amogy (Photo: Amogy)

Already a globally-traded commodity backed by existing infrastructure and transportation networks, the global market for green ammonia is expected to grow significantly in the coming years to help meet decarbonization goals in many industries, including transportation and shipping.

But often when ammonia is discussed as a marine fuel, questions arise about its handling challenges and potential dangers for crew members. When asked about these concerns, Woo noted that the company is working with the U.S. Coast Guard and partnering with classification society DNV to ensure alignment with all maritime safety standards. Amogy’s solution also has approval in principle (AIP) from classification society Lloyd’s Register.

“DNV has been working with Amogy since December 2021, focusing on the safety aspects of the development of their ammonia system,” said Hans-Christian Wintervoll, DNV’s senior consultant in maritime environmental technology. “A high-level feasibility study was executed in early 2022, and Amogy has shown great momentum in development from that point, through the HAZID [hazard identification] workshop in June the same year, to the HAZOP [hazard and operability analysis] workshop in January this year.”

Woo added that “Ammonia has been transported on board cargo vessels as a commodity for longer than probably four or five decades. Because of [this], there are well-established safety measures and protocols on how to store and transport ammonia, which we are basically piggybacking on.”

Amogy said it intends to run the converted tug through its paces later in 2023 in upstate New York, pending further safety testing and regulatory discussions.

In addition, Amogy announced in late 2022 that it is partnering with Southern Devall (formerly Southern Towing Company & Devall Towing) to deploy its technology in an ammonia tank barge in 2023. The project is currently in the design phase.

In terms of other market opportunities, Woo said Amogy sees potential for its technology in both the retrofit and newbuild markets, eventually scaling to 10+ MW systems to power larger oceangoing ships.

Woo said Amogy is committed to working with collaborators and stakeholders to reach the industry’s urgent decarbonization targets. “With the strong push from regulators as well as governments in the States, we all know that we have to really reach net zero by 2050, which has to be the case for maritime shipping as well,” he said. “Vessels built today will be on the water for another 20 or 25 years at least, so we have to start the decarbonization cycle today to reach our goal by 2050.”