Great Ships of 2025: Frederick Paup

15,000 cu. yd. Hopper Dredge = “the Cookie Monster” of Beach ReplenishmentManson Construction Co.’s Frederick Paup is the largest Trailing Suction Hopper Dredge in the United States. Designed and built specifically to meet the needs of the U.S. dredging market, she boasts 25,000 HP and volumetric capacity of over 15,000 cubic yards. Utilizing her triple Z Drives and twin Bow Thrusters enables the Frederick Paup to maneuver and dredge within the tightest channels. This further…

Blackout Due to Incorrectly Configured Generators

A gas tanker had just left its berth at the Port of Brisbane, Australia, when it lost propulsion for two minutes as two of its three electrical generators were not properly configured, an ATSB final report has confirmed.On March 15, 2025, the 100-metre, Liberian-flagged Gaschem Homer departed the BP Products berth in the Port of Brisbane, under the conduct of a harbour pilot.While it was being turned towards the port’s entrance, it experienced an electrical blackout, resulting in the total loss of all propulsion and steering control.Power was able to be restored after about two minutes…

Six New Arklow Shipping Vessels to get Octopus Battery Systems

A new series of six General Cargo vessels being built by Ferus Smit in the Netherlands for Irish ship operator Arklow Shipping will sport EST-Floattech's Octopus Lite battery system. EST-Floattech designed the system to fit the sailing profile of the vessels, a close collaboration with the yard and owner designed to provide both technology and efficiency gains.The new series of 11,000 DWT general cargo vessels represents another successful chapter in the ongoing collaboration between Ferus Smit and Arklow Shipping.The battery systems will support several onboard functions…

Robosys Automation Secures Offshore Wind Vessel Retrofit Contract

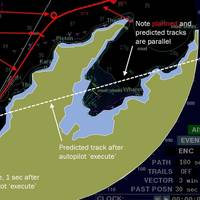

Robosys Automation, a leader in maritime autonomy, vessel control systems, and smart shipping solutions, has announced that it has secured a new contract to retrofit a 26-meter Damen 2610 Fast Crew Supplier (FCS) Twin Axe High Speed Support Vessel (HSSV), with its flagship VOYAGER AI advanced maritime autonomy software.The vessel, built in 2015 to Lloyd’s Register classification standards, is powered by twin Caterpillar C32 engines with direct drives and is equipped with an Alphatron autopilot…

Elomatic Installs Tunnel Thruster Technology Aboard METEOR IV Research Vessel

Elomatic, an international consulting and engineering company, has successfully completed the installation of its Elogrid tunnel thruster technology on the 10,000 GT special purpose research vessel, the METEOR IV, built by the MEYER FASSMER spezialchiffbau consortium.As part of a joint venture between FASSMER and MEYER Group, the 125-meter research vessel is being constructed for the German Federal Ministry of Education and Research (BMBF), to support their worldwide multifunctional and interdisciplinary projects, with a focus on climate and environmental research within the Atlantic.

Holland Shipyards Delivers Cement Carrier Vessel

Holland Shipyards Group, in collaboration with Eureka Shipping and SMT Shipping, delivered the cement carrier Tamarack earlier this week at Holland Shipyards Group’s yard in Hardinxveld-Giessendam.Tamarack is a 12,500-DWT self-discharging cement carrier designed specifically for the Great Lakes region in Canada. Built to replace two older vessels, Tamarack offers equivalent transport capacity in a more compact and efficient platform. The vessel is equipped with diesel-electric propulsion…

Ifremer’s French Oceanographic Fleet Welcomes New Research Vessel

A new research vessel built for the French oceanographic fleet operated for the National Science Community by the French national Institute of Ocean Sciences (IFREMER) has been launched at the Freire Shipyard celebrated in Vigo, Spain.The oceanographic vessel was named Anita Conti in honor of France's first woman oceanographer, as a tribute to her pioneering legacy in the exploration and study of the sea.Designed to replace the vessel Thalia, the Anita Conti will fully integrate the French Oceanographic Fleet in 2026.

Rayglass Launches “R Edition” Protector Range of RIBs

Rayglass Boats, a brand of Brunswick Corporation, has unveiled the all-new Protector R Edition range, an evolution of its high-performance RIBs. These exclusive models are engineered to deliver next-level performance, styling, and innovation.Leading the lineup is the 330 Targa R Edition, the first vessel in New Zealand to be powered by Mercury Racing’s new 400R V10 outboard engines. With a top speed exceeding 60 knots, this 10-meter boat is one of the fastest production cabin RIBs in the country.The R Edition retains the Protector hull while adding premium upgrades including custom R badging…

New Zealand Ports Order Damen’s Dredger

Damen Shipyards Group has signed a contract with Port Otago and its partner Napier Port for the delivery of a Trailing Suction Hopper Dredger (TSHD) 1000.At nearly 60 meters in length, the dredger has a maximum hopper volume of 1000m3 with twin azimuth thrusters and bow thruster to ensure appropriate maneuverability in the long entrance to Port Chalmers and Dunedin.The TSHD will arrive in New Zealand with a Green Passport under the IMO rules, after the completion of construction at Shipyard 189 in Haiphong in Vietnam.Set for delivery in 2027…

BRIX Marine Launches 11.8M Yacht Tender

BRIX Marine has announced the launch of its latest megayacht tender, the 11.8-meter T/T Kismet.This custom Naiad RHIB was designed for the tender garage on the 122-meter Kismet, recently launched by Lürssen. The 11.8-meter joins multiple other tenders in Kismet’s arsenal, and she stands out as a high-performance vessel that delivers a luxury experience from stem to stern. Powered by twin Yanmar 440HP diesel engines paired with Hamilton Jet HJX 27 waterjets, T/T Kismet reaches speeds of nearly 50 knots. Hamilton’s AVX Express system, including MouseBoat control, makes handling easy.

Grounding: Bridge Team Didn’t Know What They Didn’t Know

New Zealand’s Transport Accident Investigation Commission (TAIC) has released an interim report into the grounding of the passenger ferry Aratere in Titoki Bay, Picton, on June 21, 2024, citing lack of knowledge about the steering system.The Aratere had been in service for about 26 years, and in May 2024, KiwiRail installed a new steering control system in four of the five command consoles on the bridge. It wasn’t installed on the autopilot console, which was part of the original track pilot integrated bridge navigation system by a different manufacturer.

Passenger Vessel Collision: Propulsion Trials Too Challenging

The Marine Accident Investigation Branch (MAIB) has cited survey failings in the results of its investigation into the loss of propulsion control and subsequent contact with a moored barge by Oceandiva London.On June 22, 2023, the inland waterways passenger vessel lost propulsion control and contacted a moored hopper barge at Halfway Reach on the River Thames, London. Oceandiva London was undergoing propulsion trials as part of its Maritime and Coastguard Agency (MCA) survey required…

Crafting Dependability: The Island Vessel Built for Any Challenge

The owners of a private island in the U.S. rely on vessel transport as a lifeline to the mainland. Their boat, used for carrying supplies and even supplying medevac support in emergency situations, must be able to run at any time, in all conditions.So when it came time for their existing vessel to be replaced, the island’s owners sought a new vessel that would be rugged and reliable enough to withstand the harshest weather, said Tim Weston, the island’s general manager (note: Tim Weston is a fictitious name used to protect the identity of the island’s owners…

Strategic Marine Delivers Fast Crew Boat for Brunei's Oil and Gas Sector

Singapore-based shipbuilder Strategic Marine has delivered the Amarco S1 fast crew boat to Amarco which will be put to long-term operation for Brunei’s oil and gas sector.The 42-meter Amarco S1 vessel is powered by triple Baudouin 12M26.3 engines coupled with ZF3050 gearboxes, capable of achieving speeds of over 28.5 knots.Additionally, it is designed to be future-ready, enabling the integration of gyro stabilizer and offering the option to install a motion-compensated gangway as future capabilities.The vessel is equipped with a plug-and-play hybrid system…

Cruise Vessel MS Amera Gets a New Lease on Life

Shipowners in all sectors face the same decision: build new or refurbish older tonnage. In the booming cruise sector the decision is more pressing, particularly as new construction ships can take two to three years to build, perhaps longer today with global shipyard orderbooks packed full.When the decision was taken to upgrade the nearly 40-year-old MS Amera, trust for the project landed with BSM Cruise, the technical ship manager of MS Amera, and Wabtec channel partner VMS Group…

Gladding-Hearn Delivers Refitted Ferry to Bermuda

The Government of Bermuda’s Marine and Port Services has taken delivery of the 700-passenger ferry Bermudian after a major refit at Gladding-Hearn Shipbuilding. Engineering and project management were jointly handled by the Somerset, Mass. shipyard and Propulsion Data Services, and class oversight by Lloyd’s Register.Among the myriad items to be removed, repaired or replaced, the hull received repairs as required by class and repainted, with a goal of extending the life of the 37-year-old vessel an additional 15 years…

RAL Tugs Delivered in the Philippine Navy

Robert Allan Ltd. said that YT 027 and AT 010, a RAmparts 2700 and RAmparts 3000-W respectively were delivered to the owner, the Philippine Navy, in May 2024. The tugs were built at Josefa Slipways Inc. in Sual, Philippines and are designed by Robert Allan Ltd. to provide support to the navy’s surface vessel fleet.Propulsion machinery of YT 027 consists of two MTU 12V4000M53 diesel engines rated at 1380 kW at 1800 rpm coupling with Schottel SRP 340 Z-drives with 2.1 m diameter…

New Tugs Delivered to the Philippine Navy

The Philippine Navy in May accepted delivery of a pair of new tugs built at Josefa Slipways Inc. in Sual, Philippines.The vessels, YT 027 and AT 010, a RAmparts 2700 and RAmparts 3000-W respectively were designed by Robert Allan Ltd. to the navy’s surface vessel fleet.Propulsion machinery of YT 027 consists of two MTU 12V4000M53 diesel engines rated at 1380 kW at 1800 rpm coupling with Schottel SRP 340 Z-drives with 2.1 m diameter fixed pitch propellers.Propulsion machinery of AT 010 consists of two MTU16V4000M63 diesel engines rated at 1920 kW at 1600 rpm…

Insights: Blake Powell, JMS Naval Architects

Blake Powell, president at JMS Naval Architects, discusses his career, company and latest trends in naval architecture and marine engineering.Please give a brief professional bio, including education, experience and overview of current duties as president of JMS Naval Architects.I earned my degree in Naval Architecture from the University of California, Berkeley where I attended on a Navy ROTC scholarship and was commissioned as a Diving and Salvage Officer after I graduated.

Hydrogen-powered Vessel H2 Barge 2 Delivered

Holland Shipyards Group announced it has delivered H2 Barge 2, the second hydrogen-powered vessel for Future Proof Shipping.The vessel has undergone a complete retrofit from traditional internal combustion technology to cutting-edge hydrogen fuel technology. The project involved removing the main engine and reduction gearbox, replacing the diesel engine driving the bow thruster and diesel generators with a new modular propulsion system. This system includes electric motors, hydrogen tanks…

Eureka Shipping Orders Cement Carrier for Great Lakes Trade

Eureka Shipping announced it has ordered a new cement carrier from Holland Shipyard Group in the Netherlands for scheduled for delivery in 2025.Eureka Shipping, jointly owned by SMT Shipping and The CSL Group, said the 12,500 dwt mechanical/pneumatic cement ship will replace two older vessels in the Great Lakes region while maintaining the same cargo capacity for operations.The newbuild will be fitted with a diesel-electric a propulsion system consisting of four generator sets…

Stena Prosperous Bunkers Methanol in Singapore

Singapore is one step closer to developing its full capability to deliver methanol bunkering at a commercial scale. Close to 1,340 metric tonnes (MT) of blended methanol was bunkered ship-to-ship on May 24, and there will be another operation for simultaneous methanol bunkering and cargo operations for a container vessel this week. These operations will also test the use of mass flow meters (MFM) and digital bunkering.The blended methanol, comprising 20% ISCC-certified bio-methanol combined with conventional methanol…

Demand for Maritime Shaft Generators Increasing

30 years ago shaft generators with PTI capability kept container ships sailing at top speed. That purpose gone, PTI/PTO is making a new comeback in more cargo shipping segments, this time for reducing emissions.Retrofitting a shaft generator is not an insignificant undertaking. Around 50 tons of equipment needs to be installed into the engineroom through a hole in the hull. A new section of shaft is usually required.That a few shipowners are undertaking such projects - Klaveness Combination Carriers on the Ballard…