Partners Aim to Develop Humanoid Welding Robots for Shipyards

Italian shipbuilding giant Fincantieri has launched an industrial partnership with Generative Bionics aimed at developing a humanoid welding robot designed to operate alongside human workers in shipyard environments. The initiative aligns with Fincantieri’s broader strategy around advanced robotics, physical AI and innovation, core pillars of the Group’s new Industrial Plan.The collaboration brings together Fincantieri’s deep industrial and shipbuilding expertise with Generative Bionics’ autonomous humanoid robotics platform.

Keel Laying Ceremony Held for U.S. Army Corps of Engineers Hopper Dredge

On January 22, 2026, Eastern Shipbuilding Group (ESG) and partners, U.S. Army Corps of Engineers (USACE) and Royal IHC, held a keel laying ceremony for the ongoing construction of the Dredge DONNELLY at Eastern’s Allanton Facility.The DONNELLY is a Medium Class Hopper Dredge that has been under construction since April 2025. The vessel will replace the Dredge McFARLAND and will play a critical role in enabling USACE to continue to deliver its navigation mission.The keel laying…

The US Navy Contracting Approach Fails the Stability Test

In the 1990’s, my father was asked to attend a side shell damage on a US Navy vessel. The damage was caused by assist tug hard contact. He surveyed the damage and came back to the office to write it up. His partner Harry Ottaway saw my Dad’s commercial damage repair estimate, and said: “Henk it is a Navy ship. Double it, and double it again”. He did and came pretty close to the Navy’s claimed repair cost.This was not a complex damage, and in actual repair process was no different than the repair of a commercial vessel side shell damage…

Shipyard Wins Navy Grant to Certify Welders

Marine Group Boat Works (Marine Group), a full-service shipyard based in San Diego, won a Navy Grant to establish a maritime welding program designed to expand the skilled labor workforce supporting the U.S. Navy’s growing shipbuilding and repair demands. Marine Group was awarded this grant because it addresses workforce constraints by increasing the number of highly skilled welders certified to NAVSEA standards, thereby enhancing production resources for Navy surface ships and critical maritime assets.

ESAB Sponsors 2026 “Blue Collar Tour” to Support Skilled Trade Careers

As part of the ESAB Future Fabricators program, ESAB announced that it will again sponsor the “Blue Collar Tour,” featuring Western Welding Academy, continuing their shared mission to increase the interest and awareness of high school students in the skilled trades. The 2026 tour starts January in Stratton, Colorado, and includes 31 total stops in 21 states before concluding in mid-March.More than 4,000 students directly participated in 31 Blue Collar Tour events last year, and social media content generated during the tour earned millions of views, further spreading the tour’s impact.

AI Goes Subsea: Autonomous Welding Robot Debut

Underwater welding is one of the most demanding and hazardous tasks in the maritime and offshore world, relying heavily on a small, highly specialized pool of industrial divers. As port infrastructure ages and offshore structures expand, demand for underwater repair continues to outpace available manpower. A new research project out of Germany aims to fundamentally change that equation.Led by the German Research Center for Artificial Intelligence, the MARIOW (Maritime AI-Guided…

ESAB Launches New Tracfinder Battery-Powered Welding Tractors, Cobot Welding System

To help metal fabricators improve productivity, quality and workforce needs, ESAB has launched its new Tracfinder Rail and Tracfinder Wheel series of battery-powered welding tractors and unveiled its newly branded ROBBI Mobile cobot welding system. ROBBI is now available with the Aristo Edge 500R power source and RoboFeed Edge robotic wire feeder, which offer next-generation capabilities. Compared to manual welding, these automation solutions can typically increase output per…

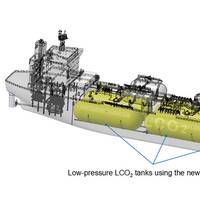

Class NK GDA for World First Vessel Tank Tech

Mitsubishi Shipbuilding Co., Ltd., part of Mitsubishi Heavy Industries (MHI) Group, and Nippon Steel Corporation have received the world’s first General Design Approval (GDA) from ClassNK for a breakthrough tank technology that enables the manufacture of large low-pressure liquefied CO₂ (LCO₂) cargo tanks without post-weld heat treatment (PWHT). The achievement marks a significant step toward scaling up CO₂ transport capacity to support global carbon capture, utilization and storage…

Dutch Shipyard Taps the Power of Robotic Welding

Next Generation Shipyards (NGS) in Lauwersoog has taken a major step toward modernizing its production line with the installation of a new state-of-the-art robotic welding system, technology that the yard says will boost efficiency, improve weld quality, and strengthen its competitive position in the specialized workboat market.The nature of shipbuilding has historically limited the usefulness of welding robots, which are typically designed for repetitive, standardized production environments.

ATDM Program Delivers Skilled Workers to the Maritime Industrial Base

The U.S. Navy needs to dramatically increase the fleet, especially submarines, but the available pool of skilled workers is not keeping pace.Submarine construction is ramping up. The Navy continues to build Virginia-class submarines, striving for two per year, and is gearing up build the new Columbia-class of nuclear-powered ballistic missile submarines. At the same time, the industry needs to support the ambitious Australia-U.S.-U.K. AUKUS program to make the Royal Australian Navy a nuclear submarine navy.Qualified workers are not only needed to build submarines…

ESAB Releases New Checkmaster 600R Resistive Load Bank

To increase the efficiency of welding equipment calibration, verification and validation, ESAB has introduced the Checkmaster 600R resistive load bank for simulating GMAW, AC/DC GTAW, SMAW and SAW arc welding processes from 150 to 600 amps. When linked with the ESAB WeldScanner multipurpose recording and measuring device, minimal user intervention is needed for calibration and validation, leading to time efficiency. Integration with the WeldScanner allows parallel operation of three Checkmaster 600R units, automatically switching resistive loads simultaneously.

ESAB's New Rogue EMP 210 PRO Compact Multiprocess Welder Hits Market

Fabrication technology specialist ESAB has announced that its new Rogue EMP 210 PRO, a compact, multiprocessor welding power source, is now in stock and available through standard distribution and online sales channels. The Rogue EMP 210 makes it easier to weld with optimized arc settings because it features an advanced digital interface and offers functions such as Synergic Control and Arc Dynamics, making it ideal for users in the light fabrication and light construction industries…

ESAB Enhances Rogue Stick and Tig Inverters with New Functionality

Fabrication technology specialist ESAB has enhanced its Rogue ES and ET line of inverters by adding DC Pulsed Stick welding functionality to all three models in the series.The models that received the upgrade include Rogue ES 151iP PRO and Rogue ES 201iP PRO Stick/Live TIG welders and the Rogue ET 201iP PRO, a TIG/Stick inverter that also offers a DC Pulsed TIG output and high-frequency (HF) TIG arc starts.All units can adjust Stick pulsing frequency between 0.2 and 100 Hz; the…

Bent But Not Broken: Lighter Icebreakers

After developing the technique some five years ago, Aker Arctic has now completed the research required to get its new design methodology for icebreaker hulls accepted into the Finish-Swedish Ice Class Rules. The method has also been adopted to Polar Class rules of several Class Societies (LR, ABS, DNV).Although the research focused on vessels typically sailing the Baltic Sea, Aker Arctic has also used the methodology in many of its recent newbuilding designs including, for example, Canada’s new icebreaker which is currently under construction.

Colonna’s Shipyard: Forged in Steel, Anchored in Legacy

Colonna’s Shipyard is a fifth-generation, family-owned medium-sized shipbuilder, led by Randall Crutchfield, Chairman & CEO, today. Founded in 1875 by 26-year-old ship carpenter Charles J. Colonna with a $2,000 loan from his brother, he founded a company that has not only withstood the test of time, but today stands ready as a multi-faceted ‘blue collar industrial complex’ to help in the effort to effectively rebuild the U.S. shipbuilding base, and more specifically to help rebuild the U.S. Navy and U.S. government-owned fleet of ships.

Seaspan Boosts Investment in Automated Welding Technology

Seaspan Shipyards has announced a $5 million investment in Novarc Technologies Inc., a North Vancouver-based full-stack AI robotics company specializing in the design and manufacturing of automated welding solutions.The funding will fuel product development and commercialization of AI-driven solutions which promise to increase industrial productivity.Seaspan has been a strategic partner and early adopter of Novarc’s welding automation technology since 2017, when it invested $500…

HII’s Ingalls Shipbuilding Hosts “Signing Day” for Shipbuilder Academy Graduates

HII’s Ingalls Shipbuilding hosted a “signing day” for the 2025 graduates of its Shipbuilder Academy at the shipyard Wednesday, April 30. This year, 43 students were offered full-time positions at Ingalls, marking the beginning of their careers with HII.The “signing day” coincided with National Apprenticeship Day, recognizing the importance of connecting individuals to meaningful careers and assisting employers in building a skilled workforce. Through hands-on training, mentorship…

PODCAST: FMD & the Building of a Defense Juggernaut

You would be hard pressed to find a corporate leader more passionate about the company they lead; more dedicated to the customer they serve. In this case it’s George Whittier, CEO, Fairbanks Morse Defense and the U.S. Navy. Upon his return less than five years ago, Whittier has driven FMD towards the top of the U.S. Navy supply heap, with a string of strategic acquisitions. Whittier discusses with Maritime Matters: The Marinelink Podcast, FMD’s rich history and promising future in helping the U.S.

NSRP Invests in Shipbuilding Tech Projects

The Executive Control Board of the National Shipbuilding Research Program (NSRP) selected 13 panel projects for award as part of the program's mission to reduce costs and expand capability for U.S. shipbuilding and ship repair. These new projects, valued at over $2.55M in government funding, were among those proposed in response to the Panel Project Solicitation issued in June 2024. Abbreviated descriptions follow; prime contractors are listed first and noted in bold text:Laser…

Small Shipyard Grant Recipients Announced

U.S. Transportation Secretary Sean P. Duffy has announced that the Maritime Administration (MARAD) has awarded $8.75 million in grants to revitalize U.S. shipyards and advance America’s maritime dominance.The funding is part of the Small Shipyard Grant program, which supports advanced training, workforce development and new technologies that strengthen U.S. shipbuilding and repair capabilities. Duffy said the program will help America counter Chinese competition and maintain freedom…

ESAB Reminder for AWS Scholarship Application Deadline

For all welding students who want to focus on education and training rather than the burden of paying for school, ESAB reminds students that the deadline to apply for AWS 2025 Foundation national, district, and section scholarships is March 1.The American Welding Society (AWS) awards more than $2.5 million in scholarships each year, including 12 scholarships in the amount of $5,000 each made possible through ESAB’s Future Fabricators program and its collaboration with the AWS Foundation.The scholarships support students working towards welding certifications…

ABS Issues AIP for Japanese LCO2 Carrier Designs

ABS issued an approval in principle (AIP) to leading Japanese companies at Gastech 2024 for two liquid carbon dioxide (LCO2) carrier designs with Type-C cargo tanks that do not require performing post-weld-heat-treatment based on the demonstration of an engineering critical assessment.ABS reviewed the drawings based on class and statutory requirements for the two designs, a 50K cubic meter carrier and a 23K cubic meter carrier, featuring Type-C cylindrical tanks made of carbon…

FloCloud: Making Welding More Efficient, Cost-Effective

InduSuite introduced FloCloud, its latest application in its line of welding and cutting digital software solutions. FloCloud includes a combination pressure and flow sensor system that digitally tracks the pressure, temperature, consumption and complete flow of gas from the manifold start to the welding operator’s arc, and automatically communicates this data. FloCloud’s dashboard and reporting system tracks every end user point and sends notifications if gas pressure drops (potential leak) or if the flow is outside the process parameters and preset WPS (weld procedure specification).