Eureka Shipping Orders Cement Carrier for Great Lakes Trade

Eureka Shipping announced it has ordered a new cement carrier from Holland Shipyard Group in the Netherlands for scheduled for delivery in 2025.Eureka Shipping, jointly owned by SMT Shipping and The CSL Group, said the 12,500 dwt mechanical/pneumatic cement ship will replace two older vessels in the Great Lakes region while maintaining the same cargo capacity for operations.The newbuild will be fitted with a diesel-electric a propulsion system consisting of four generator sets…

ECOLOG Gains 'Industry-first' Approval from ABS

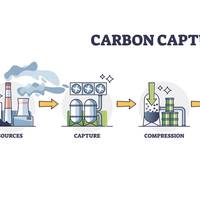

Classification society ABS announced it has awarded ECOLOG, a mid-stream Carbon Capture, Utilization and Sequestration (CCUS) service provider, with an industry first ISM Document of Compliance for the operation of liquified CO2 carriers on behalf of the Bermuda flag administration.ABS audited ECOLOG to verify compliance with the International Safety Management Code.ECOLOG plans to build and own CO2 terminals and a carrier fleet to service the emerging CCUS sector, connecting hard to abate emitters with cost competitive sequestration sites and carbon utilization facilities.“Carbon capture…

German Government Funds Rotor Sail Install on Baltrader Cement Carrier

The German government is providing funding to support the installation of an auxiliary wind propulsion system on board a cement carrier vessel.Hamburg-based Baltrader Capital GmbH & Co. KG. has signed a contract with wind propulsion systems provider Norsepower for the delivery of one 24m x 4m sized rotor sail in summer 2024. The product will be fitted on the newest cement carrier of the Baltrader fleet, Cemcommander, designed by SDC Ship Design & Consultants GmbH and built by Jiangsu Zhenjiang Shipyard (Group) Co. Ltd.The Norsepower rotor sail is a modernized version of the Flettner rotor.

US-flag Great Lakes Shipping Up 6.5% in 2023

Cargo volumes moved by U.S.-flag Great Lakes freighters in 2023 increased 6.5% compared to 2022, according to latest figures from trade group the Lake Carriers’ Association (LCA).The 81.4 million tons of cargo transported by the U.S. laker fleet 2023 was 1.2% above the fleet’s five-year average, LCA said.Iron ore cargos totaled 42.4 million tons, an increase of 13.4% compared to a year earlier, while limestone shipments increased by 3.9% to 24.6 million tons. Sand shipments increased by 12.4%.Coal cargos were down 9.7% to 8.4 million tons.

Ukraine's Black Sea Grain Export Success Tested by Red Sea Crisis

Ukraine has managed to boost its Black Sea grain exports to a level not seen since before Russia's invasion, although the Red Sea shipping crisis poses a new challenge to its crucial agricultural trade.Kyiv's success in replacing a UN-backed Black Sea export deal with its own shipping scheme has brought relief for Ukrainian farmers and importing countries while representing a naval breakthrough for Ukraine's military as a land counteroffensive has stalled.The export turnaround…

NAVTOR: Simplifying Ships from Shore

In a climate of increasing complexity, with new regulations, environmental concerns and commercial considerations, how can owners and operators control their fleets, and futures, from dry land? NAVTOR’s Tor Håkon Svanes believes the answer lies in innovation and integration – developing solutions that evolve in line with the needs of a dynamic global industry.“There are smarter ways to do things.”Tor Håkon Svanes, the NavFleet Product Manager at NAVTOR, is referring to a recent chat with a new customer.The unnamed fleet manager…

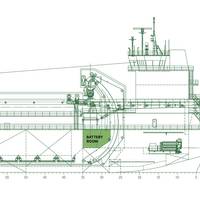

CSL and Adbri to Build Fully Electric Battery Capable Self-unloading Ship

Canadian shipping company CSL announced it is partnering with Adelaide Brighton Cement Ltd. (Adbri) to build and operate the world’s first fully electric battery capable self-unloading vessel.Under a 20-year strategic partnership agreement, the custom-designed ship will replace Adbri’s Accolade II and will support the company’s limestone operations in South Australia with a focus on enhanced efficiency and environmental responsibility. The ship will carry up to 2.7 million tonnes of limestone per year…

Upper Miss Navigation Season Draws to a Close

The 2023 navigation season has drawn to a close on the Upper Mississippi River.A 15-barge tow pushed by the towboat Thomas Erickson, the last of the season, departed Lock and Dam 10, near Guttenberg, Iowa, December 3, the U.S. Army Corps of Engineers, St. Paul District said.The 2023 season commence March 12, when the towboat Phillip M Pfeffer broke its way through the ice of Lake Pepin to travel to St. Paul, Minnesota.With the 2023 navigation season in the rearview, St. Paul District staff will remain busy this coming winter with maintenance projects at Lock and Dam 2…

Carbon Capture Chasm Exposed at Climate Summit

Carbon capture and storage has emerged as flashpoint at the UN climate conference in Dubai about how big a role it is destined to play in reaching the target of net zero emissions.It has also prompted an unusual and bad-tempered confrontation between senior officials at the International Energy Agency (IEA) and the Organization of the Petroleum Exporting Countries (OPEC).In the run up to the conference, the IEA called on oil and gas producers to let go of "the illusion that implausibly…

Deutsche Bank Sets Emissions Targets for Shipping Clients

Deutsche Bank has set emissions reduction targets for loans to clients in the coal mining, cement and shipping sectors and now has a net-zero plan for 55% of its financed emissions, its chief sustainability officer told Reuters.A key funder to polluting sectors, Germany's biggest lender, like many of its peers, is under increasing pressure from policymakers and investors to push clients to curb climate-damaging emissions.Its corporate loan book stood at 107 billion euros ($112.72 billion) at the end of 2022."Once we have pathways…

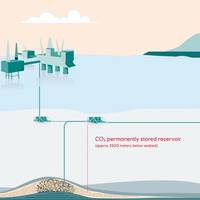

Northern Lights CCS: Trailblazing the Path to Europe’s Net Zero Emissions

In the global quest for achieving net zero emissions and slowing down global warming, carbon capture and storage (CCUS) technology has emerged as an important solution. Among the notable projects being developed in the field is the Northern Lights offshore carbon capture and storage project in Norway, a country with long experience with offshore CO2 storage.The transition to a sustainable energy future requires innovative solutions that go beyond simply halting fossil fuel projects.

New Monopile and Tower Fabrication Facility to Open in Maryland

Baltimore-based offshore wind energy development company US Wind, Inc. announced its plan to form a long-term partnership with Haizea Wind Group Management S.L. to manage and operate Sparrows Point Steel, Maryland’s first permanent offshore wind factory in Baltimore County, Maryland. The facility will be available to manufacture steel components for the U.S. offshore wind industry, including monopiles and towers.“The partnership between US Wind and Haizea to lead Sparrows Point Steel will create one of the premier offshore wind industrial facilities in the world…

US Firm Says Mexican Authorities Illegally Seized Its Port Terminal

U.S. construction materials firm Vulcan Materials Co said on Monday that Mexican security forces illegally took possession last week of its port terminal in southern Mexico, as an extended legal battle over its nearby limestone mining activities plays out.The incident took place last Tuesday night at the terminal in the popular tourist hub of Playa del Carmen, and follows a five-year fight with the government over Vulcan's concessions punctuated by sharp criticism from the country's president last year.Vulcan…

India Coal is Back in Business

India's coal industry celebrated the return of its major conference after a three-year pandemic hiatus by presenting a bullish view of demand, rising supply from new mines and strong demand for imports."King coal is coming back and coming with a big bang," Anil Kumar Jha, the chairman of Jindal Power Ltd., told the Coaltrans India conference, held this week for the first time since February 2020.The sentiment was echoed by virtually every speaker at the event, although there was a wide variety of views as to how successful India will be at ramping up coal domestic coal output…

OSK Group Fortifies Strategic Segment of OSK Defense

Danish ship designers OSK continue to cement its position within naval ship design with the establishment of OSK Defense – a strategic department solely designated to specialized naval design, both nationally and internationally. Heading the new department will be Commander Lars Povl Jensen, who has more than twenty years’ experience in international and arctic naval operations.In October 2022, the Danish government earmarked €5 billion for investments in the Royal Danish Navy.

Wisconsin Awards $5.3 Million in Harbor Maintenance Grants

Wisconsin Gov. Tony Evers, together with the state's Department of Transportation (WisDOT), announced grants totaling $5.3 million for seven harbor maintenance and improvement projects to promote waterborne freight and economic development.“From the Great Lakes to the Mississippi River, Wisconsin’s unique geography provides our state opportunities to grow our economy and help our businesses reach markets worldwide,” said Gov. Evers. “These grants will help maintain our harbors and ensure our ports are secure and reliable…

Inside the Chinese Port Deal that Divided the German Government

The German government has become divided over a deal, agreed last month, which saw Chinese conglomerate Cosco invest in the Port of Hamburg. The deal had been in the works since September 2021 and was championed by the chancellor (and Hamburg’s former mayor), Olaf Scholz.Scholz’s coalition partners have been vocal in criticising the deal. Chief among them is Robert Habeck, Greens member and Scholz’s economics minister, who expressed his fear that Germany was becoming dependent on Chinese business.

NETSCo Promotes Two Senior Leaders

NETSCo, a naval architecture and marine engineering firm located in Columbia Station, Ohio, has promoted two of its senior employees to new leadership roles. David Hossenlopp, P.E, has been promoted to the position of Chief Naval Architect, and Nick Hunter, P.E. to Senior Naval Architect / Marine Engineer.“David has been with NETSCo since 2013,” said Richard Mueller, CEO/President, “and throughout this time he has very successfully been involved with a large variety of projects…

Malin Group Acquires Clyde Corrosion

Clyde Corrosion Control Ltd has become part of the Malin Group, with the formal agreement documenting sale of all shares in the company being signed at the Group’s South Rotunda headquarters on October 7. Clyde Corrosion Control will now form a specialist division under the Group’s Malin Newbuild business unit, who specialize in large scale fabrication projects.Founded in 2002 by Bonnie Lowson and rooted in the Clyde’s industrial legacy, Clyde Corrosion Control has an established customer base in Scotland and beyond, spanning the oil and gas, nuclear, construction and renewables sectors.

95-year-old Laker S.T. Crapo to Be Scrapped

A nearly century-old vessel used as cement storage at the LaFargeHolcim terminal on the Fox River for the past 25 years is set to be scrapped.On Friday at sunrise, the S.T. Crapo began its journey under tow from the Port of Green Bay to be scrapped at Port Colborne, Ontario, Canada.Built in River Rouge, Mich., the S.T. Crapo was launched in 1927 as a self-unloading cement carrier operating on the Great Lakes, primarily carrying cement from Alpena, Mich.By the mid-1990s, the vessel was the last coal-fired freighter on the Great Lakes…

Amplify Energy to Pay $5M to Settle Criminal Charges over California Oil Spill

California officials [last] Thursday said Amplify Energy Corp agreed to plead no contest to six criminal charges and pay nearly $5 million in penalties and fines in connection with a crude oil spill last year that killed birds and fouled beaches.The announcement was the latest legal effort to hold the Texas-based oil company accountable for a subsea pipeline leak that released some 558 barrels (25,000 gallons) of crude oil into the Pacific Ocean off the coast of Huntington Beach in southern California in October of last year.At a news conference broadcast live on the internet…

Sunken Tugs Recovered from the Bottom of the Mersey River

Salvors have removed two tugs from the Mersey River in Devonport on the northwest coast of Tasmania that had been sunk by a cement carrier in January.New South Wales based emergency response, salvage and environmental support specialist, United Salvage, engaged AAL Shipping to supply the 31,000DWT 700 tonne heavy lift vessel AAL Melbourne for lifting of the tugs and their onward shipment along the East Coast to Brisbane. The first tug, the 420 tonne York Cove, was pulled out of…

US Inland Waterway Infrastructure: Riding a Good News Wave

The inland waterways have enjoyed several positive developments toward modernization of the system, particularly over the last two years.Annual appropriations that fund the U.S. Army Corps of Engineers’ Civil Works mission have been steadily on the rise for the last nine fiscal years, specifically the Construction and Operations & Maintenance (O&M) accounts have been funded at historic levels. The passage of the Infrastructure Investment and Jobs Act (IIJA) in 2021 provided a…