Bristol Harbor Group Hires Kyle Pagan

Briston. R.I. based naval architecture and marine engineering frim Bristol Harbor Group, Inc. (BHGI) announced it has hired Kyle Pagan as a naval architect.Pagan holds a Master’s degree in Naval Architecture and Marine Engineering from the University of New Orleans and a Bachelor’s degree in Petroleum Engineering from Louisiana State University. For his graduate research, he conducted an in-depth study of the performance of 3D printing materials under the influence of water exposure…

Bristol Harbor Group Promotes Eling

Bristol, R.I. based naval architecture and marine engineering form Bristol Harbor Group, Inc. (BHGI) announced it has promoted a member of its team, Daniel P. Eling, P.E., to a managerial position.Eling, a senior naval architect with six years of experience at the firm, has been promoted to the role of engineering manager.Eling holds a Bachelor of Science in Ocean Engineering from Virginia Polytechnic Institute and State University. He is a licensed Professional Engineer in the Commonwealth of Virginia and the State of Rhode Island.

Bristol Harbor Group to Design Ferry for Casco Bay Lines

Bristol, R.I. based naval architecture and marine engineering firm Bristol Harbor Group, Inc. (BHGI) has been selected by Casco Bay Lines (CBL), located in Portland, Maine, to provide naval architecture and marine engineering services for the evaluation and design of a new sub-chapter K passenger/vehicle ferry that will be operated year round in the coastal waters of Casco Bay.The new vessel will replace the 98-foot-long, 399-passenger Maquoit II, built by East Boothbay, Maine shipbuilder Washburn & Doughty in 1994.BHGI said it will be responsible for developing a preliminary design report…

BHGI Hires Naval Architects Althouse and Kennedy

Bristol, R.I. based naval architecture, marine engineering and consulting firm Bristol Harbor Group, Inc. (BHGI) announced the continued expansion of its naval architecture and marine engineering firm with two new hires: Taylor Althouse and Kasey Kennedy.Althouse joined BHGI as a Naval Architect. Althouse graduated from the University of Michigan with a Master of Science in Engineering in Naval Architecture and Marine Engineering. During his time at the University of Michigan, Althouse interned at Hornbeck Offshore Services, LLC.

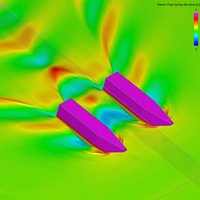

New Manned Barge Designed for Rocket Transport

A new barge has been designed to transport rockets for spacecraft launch service provider United Launch Alliance (ULA).Naval architecture firm Bristol Harbor Group, Inc. (BHGI) said it was recently selected by ULA to design a river and oceangoing manned roll-on / roll-off barge for the transportation of its Vulcan Centaur rockets. The barge will be supported by an operations and cargo monitoring crew.In support of ULA’s competitive solicitation for ship fabrication this summer…

Bristol Harbor Group Promotes Two

Naval architecture and marine engineering firm Bristol Harbor Group, Inc. (BHGI) announced the promotion of two members of its team, Ian M. Lawson, P.E. and Teri L. LaForest, P.E.Upon earning his Professional Engineer License in Rhode Island, Lawson has been promoted to Senior Naval Architect. He has been with BHGI for over five years, during which he has filled both engineering and project management roles and specializes in the development of novel vessel designs and concepts, particularly related to alternative fuels and electric propulsion systems.

Bristol Harbor Group Wins USACE IDC Contract

Bristol Harbor Group, Inc. (BHGI) won an Indefinite Delivery Contract (IDC) for naval architecture and marine engineering services for the United States Army Corps of Engineers (USACE), Philadelphia District, Marine Design Center. This contract continues BHGI’s partnership with the Marine Design Center (MDC). Some of the projects BHGI has worked on for the USACE include, but are not limited to, retrofits, finite element analyses, electric load analyses, vibration analyses, computational fluid dynamics analyses, as well as barge, towboat and dredge design.In partnership since 2010, BHGI and the MDC team have worked on a wide variety of projects both for the USACE and other federal agencies, including the United States Coast Guard, NASA, and the National Park Service.

BHGI Hires Naval Achitect Delaney

Bristol, R.I.-based naval architecture and marine engineering firm Bristol Harbor Group, Inc. (BHGI) announced it has hired Braden Delaney, as a naval architect. He graduated from the University of Michigan in Ann Arbor, Mich. with an B.S.E. in naval architecture and marine engineering.Prior to joining BHGI, Delaney interned at NASSCO and NAVSEA, providing engineering support for shipyard operations in addition to interning as a salvage naval architect. Delaney is also a member of the Society of Naval Architects and Marine Engineers (SNAME).

Bollinger to Build Pontoon Launcher for Electric Boat

Bollinger Shipyards on Monday announced it will construct a new pontoon launcher for General Dynamics Electric Boat to support the construction and launching of the U.S. Navy’s Columbia Class Ballistic Missile Submarines.The concept and contract design for the 496- by 95-foot pontoon launcher was performed by the Bristol Harbor Group in Rhode Island. The detail design engineering will be performed at the Bollinger facility in Lockport, La. The launcher is scheduled to be delivered…

New Ocean Transport Barge Arrives at Electric Boat’s Groton Shipyard

On Monday, the new ocean transport barge Holland arrived at Electric Boat’s Groton Shipyard. The barge was purpose-built to support delivery of Columbia class ballistic missile submarines. General Dynamics Electric Boat is the prime contractor on construction of the Columbia class.The Holland was designed by Bristol Harbor Group, Inc. (BHGI) and constructed by Bollinger Shipyards, LLC, of Lockport, La. The namesake of the new barge is John Holland, the Irish-born immigrant who designed the first submarine purchased by the U.S. Navy.

Electric Boat's New Submarine Transport Barge Christened

Bollinger Shipyards on Saturday christened the Holland, an ocean transport barge for General Dynamics Electric Boat. The Holland will support the construction and maintenance of the United States Navy’s Columbia Class ballistic missile submarines and Virginia Class fast attack submarines. General Dynamics Electric Boat is the prime contractor on the design and build of the Columbia Class submarine, which will replace the aging Ohio Class ballistic missile submarines.“Bollinger…

Hamel Joins Bristol Harbor Group

Naval architecture and marine engineering firm Bristol Harbor Group, Inc. (BHGI) announced it has hired Jeb Hamel as a naval architect.Hamel graduated from the University of Michigan in Ann Arbor, Mich. with an M.S.E. in Naval Architecture and Marine Engineering.Prior to joining BHGI, Hamel worked as a naval architecture intern at BMT Designers and Planners in Arlington, Va., where he gained experience creating general arrangement plans and performing stress and weights calculations for naval designs. He has experience in AutoCAD, Excel, Navisworks and MATLAB.

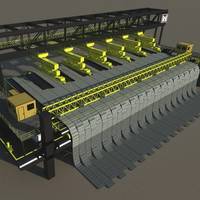

MacGregor Wins Order for 36 Traction Winch Systems

MacGregor, part of Cargotec, has secured an order from SIA Solutions LLC to deliver 36 traction winch systems, 72 storage reel brakes and electrical control systems to the specialised concrete mat sinking unit, Armor 1, currently under construction at Thoma-Sea Marine Constructors LLC, Houma, La. for the United States Army Corps of Engineers (USACE).The order was booked into Cargotec’s 2020 fourth quarter order intake. Equipment delivery is planned for the middle of 2021, with…

Bollinger to Build Electric Boat's New Floating Dry Dock

Louisiana-based Bollinger Shipyards announced Wednesday it will construct a state-of-the-art, floating dry dock for Groton, Conn. shipyard General Dynamics Electric Boat to support the construction and maintenance of the United States’ new Columbia Class of Ballistic Missile Submarines.The detail design engineering will be performed at the Bollinger facility in Lockport, La. The concept and contract design for the 618ft by 140ft dry dock was performed by the Bristol Harbor Group in Rhode Island.

Icebreaking Tug Delivered to NY Power Authority

A new icebreaking tugboat built by Blount Boats in Rhode Island has been delivered to the New York Power Authority (NYPA) to work in the Niagara River to help alleviate shoreline flooding and reduce the likelihood of ice limiting the power production at large hydro plants along the Niagara River. The Breaker II joins a fleet of three boats that work every winter to install the Lake Erie—Niagara River Ice Boom—a series of 22 spans of steel pontoons that straddle the mouth of the…

Bristol Harbor Group Hires Linden

Bristol Harbor Group, Inc. (BHGI) said Tommy Linden has joined the company's naval architecture and marine engineering practice as a naval architect. Linden graduated from Webb Institute with a B.S. in Naval Architecture and Marine Engineering. During his time at Webb, he interned at BHGI, as well as the Naval Surface Warfare Center Carderock Division, Eagle Bulk, Newport News Shipbuilding, and General Dynamics Electric Boat.Linden is a member of the Society of Naval Architects and Marine Engineers (SNAME) and the American Society of Naval Engineers (ASNE).Bristol, R.I.

BHGI Scores USACE Contract

Bristol Harbor Group, Inc. (BHGI) was recently awarded an Indefinite Delivery Contract (IDC) for naval architecture and marine engineering services for the U.S. Army Corps of Engineers (USACE), Philadelphia District, Marine Design Center. This contract continues BHGI’s partnership with the Marine Design Center (MDC). Some of the projects BHGI has worked on for the USACE include, but are not limited to, retrofits, finite element analyses, electric load analyses, vibration analyses and computational fluid dynamics analyses as well as barge, towboat and dredge design.In partnership with MDC since 2010, BHGI and the MDC team worked on a wide variety of projects both for the USACE and other federal agencies, including the U.S. Coast Guard and NASA.

Blount Boats: Ferries, Offshore Wind both Dominate Present, Future

Marine News recently visited the Blount Boats facility in Warren, Rhode Island. While the year 2019 might be the ‘year of the woman’ in the eyes of the International Maritime Organization, the two women at the head of Blount Boats – Marcia & Julie Blount– have been a driving force in the U.S. boatbuilding market for decades. As Blount’s celebrates its 70th anniversary, read about the storied yard’s promising future.Founded in 1949, Blount Boats is a full-service shipyard with a customer base comprised of a variety of commercial and government entities including the U.S. Coast Guard, U.S.

BHGI Completes Buoy Design for NYPA

Bristol Harbor Group, Inc. (BHGI) was contracted by the New York Power Authority (NYPA) to provide naval architecture and marine engineering services to review and analyze a Canadian Coast Guard buoy for required internal ballast and mooring in order to secure the buoy moorings in tailrace waters.NYPA’s fast water warning buoys had reached the end of their life cycle. BHGI conducted a site visit at the Moses-Saunders Power Dam in Massena, NY. The purpose of the visit was to inspect…

Mat Sinking Unit in Modernization Drive

Millions of dollars of goods are transported up and down the Mississippi every year. This transportation is made possible, in part, by the U.S. Army Corps of Engineers (USACE) Mat Sinking Unit and its crew, who work tirelessly each season to protect the riverbanks with concrete mats and prevent erosion.The Mat Sinking Unit was built in 1940, widened in 1960 and is being replaced over the next several years with new and improved plant. The new design will double the number of mat squares that can be placed in a season.USACE Vicksburg District (MVK)…

Interview: Cory Wood, VP, Bristol Harbor Group

Born at the University of Michigan in the early 1990s, Bristol Harbor Group (BHG) has grown into a diverse and widely respected naval architecture and marine engineering firm. Cory Wood, Vice President and one of the four co-founders of BHG, discusses the companies past and design drivers to power its future.The University of Michigan runs one of the most prestigious naval architecture and marine engineering programs in the country, but when Cory Wood entered U of M, he did so with the intent of becoming an aerospace engineer.

New Barge for EB to Transport Sub Modules

Bollinger Shipyards won a contract to build an ocean transport barge for General Dynamics Electric Boat, a barge designed and built to transport submarine modules to Electric Boat’s Groton Shipyard for final assembly and test. The concept and contract design for the 395 x 100ft. Ocean Transport Barge was performed by the Bristol Harbor Group. The detail design engineering will be performed at the Bollinger Lockport New Construction facility in Lockport, Louisiana and the construction will take place at the Bollinger Marine Fabrication facility in Amelia, La. Delivery is scheduled for 2021.

BHGI Awarded IDIQ Contract Through SeaPort-NxG

Bristol Harbor Group, Inc. (BHGI) has announced that it was awarded a five-year indefinite-delivery, indefinite quantity contract through the U.S. Navy’s most recent contract vehicle, SeaPort-NxG. Through this contract, BHGI will have the ability to bid on various task orders throughout the entire contract period.