Damen and PVE Equipment USA Sign Dredge Pump Reseller Agreement

Damen Shipyards Group has signed a reseller agreement with PVE Equipment USA (PVE USA) that appoints PVE as authorised partner and official supplier for the sales, service, and parts supply of Damen’s DOP submersible dredge pumps across the US.Under the agreement, PVE USA will leverage its nationwide network in piling, vibro, and foundation equipment to expand US access to DOP pumps, while providing local stock and service, trained technicians, and quick access to parts to minimize downtime for contractors in marine construction, port maintenance, and environmental dredging.

Great Lakes Dredge & Dock Takes Delivery of Hopper Dredge

Great Lakes Dredge & Dock, the largest provider of dredging services in the United States, has taken delivery of its newest Jones Act-compliant hopper dredge, the Amelia Island from the Conrad Shipyard in Morgan City, Louisiana.The Amelia Island is specially designed for efficient and safe operations along shallow and narrow waters throughout all U.S. coastlines. The vessel is approximately 346 feet in length, 69 feet in breadth, 23 feet in depth with 16,500 total horsepower installed.

Ports Urge Congress to Reverse Infrastructure Funding Cuts

The American Association of Port Authorities (AAPA) and a broad coalition of every donor and energy transfer port have sent the House and Senate Appropriations Committees and the Energy and Water Development Subcommittees leaders a letter, urging them to reverse a funding diversion and restore critical support for ports through the FY2026 appropriations process.Without restoration of Section 102 and 2106 funding from the Harbor Maintenance Trust Fund (HMTF), the U.S. port system…

Moored Dredger Sinks off Singapore, No Casualties Reported

The Maritime and Port Authority of Singapore (MPA) has reported that a moored Belize-registered dredger, KSE Hitachi, had sunk off Tuas in Singapore.According to MPA, there were no personnel reported to be on board the dredger at the time of the incident, with port operations remaining unaffected.MPA is investigating the incident, and navigational broadcast has been issued to advise passing vessels to keep clear of the area.The dredger’s company is making arrangements to salvage the vessel.Three MPA patrol crafts have been deployed to the site to render assistance.

Construction of Damen’s First Cutter Suction Dredger in Azerbaijan Well Underway

The first cutter suction dredger to be built in Azerbaijan, Damen Cutter Suction Dredger (CSD) 650, is progressing according to schedule, with a planned delivery later in 2025.Baku Shipyard is building the CSD 650, with the design of the dredger and its materials package delivered by Damen Shipyards Group.The dredger, which will be ready later this year, will be operated by the Port of Baku, a transport hub on the western shore of the Caspian Sea.Named Engineer Soltan Kazimov…

New Zealand Ports Order Damen’s Dredger

Damen Shipyards Group has signed a contract with Port Otago and its partner Napier Port for the delivery of a Trailing Suction Hopper Dredger (TSHD) 1000.At nearly 60 meters in length, the dredger has a maximum hopper volume of 1000m3 with twin azimuth thrusters and bow thruster to ensure appropriate maneuverability in the long entrance to Port Chalmers and Dunedin.The TSHD will arrive in New Zealand with a Green Passport under the IMO rules, after the completion of construction at Shipyard 189 in Haiphong in Vietnam.Set for delivery in 2027…

Damen Delivers Newbuild Dredger to Indonesian Customer

Dutch shipbuilder Damen has delivered the first-of-its-series Cutter Suction Dredger (CSD) 600 to an Indonesian customer, PT. Dua Samudera Perkasa.The vessel was sold immediately after completion at the Damen Dredging Equipment yard. It form part of a complete dredging package, which includes ship transportation, training of the crew on location as well as dredge spares to facilitate maintenance duties.The CSD600, which is being shipped as deck cargo at present, is a brand-new type of dismountable dredger…

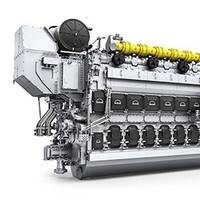

MAN’s Most Powerful Medium-Speed Engine Chosen for TSHD

MAN Energy Solutions has won the contract from Royal Boskalis to supply 3 × MAN 49/60 engines for a 31,000 m³ Trailing Suction Hopper Dredger (TSHD).Each engine will come accompanied by an exhaust-gas after-treatment system, namely an MAN Low-Pressure Selective Catalytic Reduction (LP-SCR) system, that ensures IMO Tier III compliance. The newbuilding will be built at Dutch shipbuilding company, Royal IHC, at its Krimpen aan den IJssel yard and is expected to enter service in mid-2026.The TSHD will be diesel-electric powered with two Azipods to allow vessel operation even at shallow draught.

Van Oord Takes Delivery of Third Dual-fuel LNG Dredger

Van Oord Ship Management has taken delivery of its third dual-fuel trailing suction hopper dredger (TSHD), from Seatrium in Singapore.The delivery of Vox Alexia, the final unit of a series of three dual-fuel LNG-powered dredgers, follows the first and second dredger newbuilds Vox Ariane and Vox Apolonia delivered in April and December 2022 respectively.Vox Alexia is IMO Tier III compliant, built to Bureau Veritas (BV) class and has a hopper capacity of 10,500m3. Certified with the BV Green Passport and Clean Ship notations…

Merco Vial Orders Cutter Suction Dredger from Damen

Argentinian contractor Merco Vial S.A. has ordered a Damen CSD650 cutter suction dredger. Damen, a Dutch shipbuilder, said Tuesday that the the delivery of the dredger included the supply of a matching booster station.The cutter suction dredger CSD650 is a customized stock vessel, tailored to Merco Vial’s requirements, and Damen said the vessel would be delivered "shortly."According to Damen, the CSD650 is a dismountable dredger with a cutter power of 700 kW and a maximum dredging depth of -18 meters."The overall length exceeds 61 m…

MAN PrimeServ Inks Deal for Dredger Samuel de Champlain

MAN PrimeServ, the after-sales service brand of MAN Energy Solutions, signed a long-term service agreement (LTSA) with GIE Dragages-Ports, which includes inspection kits and preventative maintenance services as well as remote assistance (PrimeServ Assist) and engine-fluid analysis (PrimeServ LAB).The Samuel de Champlain dredger (117 m, 8,500 cu. m.) belongs to GIE Dragages-Ports, headquartered in Rouen, and is fitted out and operated by the Grand Port Maritime de Nantes Saint-Nazaire (Nantes Saint-Nazaire Port).Three years ago…

Van Oord Orders Two Water Injection Dredgers

Dutch shipbuilder Kooiman Marine Group said it has secured a contract from Dutch dredging and marine services firm Van Oord to build two Water Injection Dredgers (WID) for delivery scheduled in the first half of 2024.The order follows the previous deliveries of the WIDs Maas and the Mersey delivered in mid-2021."The new vessels will have the same specifications, supplemented by innovative optimizations. The first of the two vessels will be commissioned in the first half of 2024…

Great Lakes Dredge & Dock's 1Q Profit, Revenue Rise

Great Lakes Dredge & Dock Corporation reported a first-quarter net income of 11.1 million in the first quarter of 2022 an increase compared to first-quarter 2021 income of $8.8 million.Revenue for the quarter was $194.3 million, an increase of $16.7 million from the first quarter of 2021. The higher revenue in the first quarter of 2022 was due to higher domestic capital and coastal protection revenue, offset partially by a decrease in revenue from maintenance dredging, rivers and lakes…

Royal IHC Delivers Trailing Suction Hopper Dredger to Mexico's SEMAR

Dutch shipbuilder Royal IHC has delivered a trailing suction hopper dredger (TSHD) to SEMAR (Secretaria de Marina) at the Port of Veracruz in Mexico. The Bahia San Carlos dredger, of the n Easydredge 2700 type, was built from stock at the Krimpen aan de IJssel and Kinderdijk shipyards in the Netherlands. Being built from the stock program allowed Royal IHC to comply with SEMAR’s request for an ultra-short delivery time, the Dutch company said.Following successful sea trials in the North Sea in October…

Dutch Dredging Giants to Deepen Approach Channel to UK Harbor. Deal Valued at $165M

Dutch marine and offshore contractor Van Oord has, together with its compatriot Boskalis, secured a contract for deepening of the approach channel and inner harbor at the Harwich Haven in the UK, allowing access to large container ships.The contract valued around 140 million euros ($165 million) and split 50/50 between Van Oord and Boskalis has been awarded by Harwich Haven Authority. The project entails the deepening of the approach channel and inner harbor from minus 14.5 to…

Paraguay: T&C Orders Damen Cutter Suction Dredger

Paraguayan firm Ingeniería de Topografía y Caminos S.A. (T&C) has ordered a customised Cutter Suction Dredger (CSD) 500 from the Dutch shipbuilder Damen.T&C will use the dredger to transform the southern riverbank of the capital Asunción, in the Costanera Sur project. "The modular dredger will sharply increase sand production, required to meet the ambitious projects deadlines," Damen said.According to Damen, parts of the city have flooded annually for decades due to their proximity to the river.

I am Spartacus! - DEME Names Mega Cutter Suction Dredger

Belgium-based offshore and dredging services firm DEME last Friday held a naming ceremony for the "mega" cutter suction dredger Spartacus," for which it says is the most powerful cutter suction dredger in the world."...a vessel like ‘Spartacus’ has never been seen before in the industry. With a total installed power of 44,180 kW, its production rates and ability to cut hard soil are unrivaled," DEME said.Annik Penders, the wife of the Prime Minister of Belgium Alexander De Croo…

Van Oord Inks Service Agreement with ABB Turbocharging

Dutch dredging company Van Oord signed a three-year agreement with ABB Turbocharging to provide fleetwide maintenance and optimization services. The agreement comes as two Van Oord vessels receive the first turbocharger upgrades of their kind in the dredger sector, an upgrade at saving fuel and carbon emissions over the next decade.The service agreement, which marks more than 30 years of cooperation between Van Oord and ABB Turbocharging, is designed to help the owner minimize lifecycle costs and improve emissions across its fleet.

Belgium: In a First, Dredging Work in Flanders Powered by LNG

Belgium-based marine contractor DEME, on Wednesday, announced "a first" in Flanders, a region in the northern part of Belgium.Namely, its dual fuel trailing suction hopper dredger (TSHD) ‘Scheldt River’ is currently carrying out maintenance dredging work on the Scheldt river and during this work, the vessel is operating on LNG.In another milestone, DEME said that the ‘Scheldt River’ last week became the first dredger to be bunkered with LNG in the Port of Antwerp, near the Kallo lock.

DREDGING: Royal IHC, Arab Potash Launch CSD Alyarmouk

Arab Potash Company's (APC) newest cutter suction dredger (CSD) was launched at Royal IHC’s shipyard in Krimpen a/d IJssel, The Netherlands, on Wednesday. APC will use Alyarmouk at its site in Jordan, where it will cut and remove crystallized salt under harsh conditions.The custom-built vessel is a 3,557-kilowatt CSD and a further developed copy of the dredger Jarash, which IHC delivered to APC in 2018.Alyarmouk is the last of three contracts signed between APC and IHC earlier this year.

Keppel Delivers Fifth Trailing Suction Hopper Dredger to Jan De Nul

Keppel Offshore & Marine has delivered another Trailing Suction Hopper Dredger (TSHD) to Jan De Nul Group.Named Ortelius, the 6000m3 Trailing Suction Hopper Dredger, is the fifth dredger that Keppel O&M has delivered to Jan De Nul Group, following the delivery of three 3500m3 TSHDs and one 6000m3 TSHD last year. According to the shipbuilder, all five dredgers are Ultra-Low Emission vessels (ULEv) and the world's first European Union (EU) Stage Vdredgers.Ortelius is fitted with a two-stage filtering technique for exhaust gases.

The Philippines: Boskalis Nets Largest Deal in Its History

Dutch marine and dredging giant Boskalis has won a contract for the land development design and construction of the Manila International Airport (MIA) in the Philippines, in what the company said Tuesday was its largest contract ever.The contract was awarded by San Miguel Aerocity Inc (SMAI), a subsidiary of San Miguel Corporation (SMC), one of the largest companies in the Philippines. SMAI is the concession holder of MIA, which is a greenfield development aimed at serving the growing air traffic demands in the Greater Capital Region of Manila and will complement the air traffic operations at the existing and congested Ninoy Aquino International Airport.

DEME Bags Its Largest Ever Dredging Deal

The Belgian dredging and offshore installation firm DEME said Friday it had secured its largest ever dredging and land reclamation contract.The contract is for work for the Abu Qir port project in Egypt. The project will see the deployment of DEME’s giant new cutter suction dredger ‘Spartacus’.While it said the contract was a "large" one, and its largest ever in the dredging and reclamation space, DEME did not provide the exact figure. However, it did say that a “large” contract…